7

Dimensional adjustment

Lower the main frame by turning the crank handle counter-

clockwise until the indicator plate points to the scale gradua-

tion indicating the desired finished dimension. One full turn of

the crank handle moves the main frame 2 mm (3/32”) up or

down. The scale has inch graduations on its right side and

metric graduations on its left side.

Adjusting depth of cut

The maximum depth of cut differs depending upon the width

of workpiece being cut. Refer to the table. When you need to

remove more than the amount specified in the table, set the

depth of cut shallower than the amount and make two or

more passes.

To adjust the depth of cut, proceed as follows.

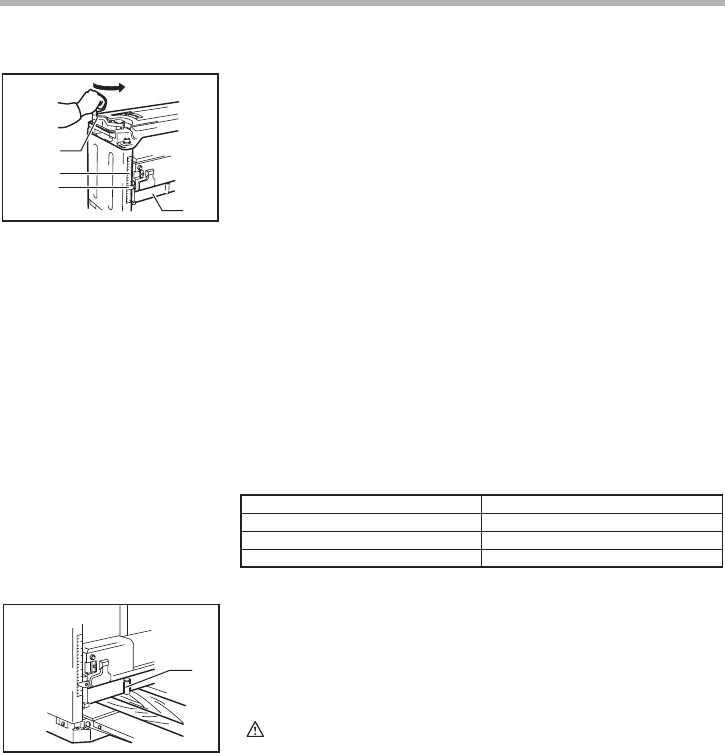

Insert the workpiece flat on the table top. Lower the main

frame by turning the crank handle counterclockwise. The

depth gauge will rise and the amount of gauge rise indicates

the depth of cut.

CAUTION:

• Always lower the main frame when aligning the indicator

plate with the graduation indicating the desired finished

dimension. If you raise the main frame into the desired

finished dimension, additional play in the screw may

result. This may cause an undesired finished dimension.

• Always place the workpiece flat on the table top when

predetermining the depth of cut. Otherwise, the

predetermined depth of cut will differ from actual depth

of cut.

1. Crank handle

2. Scale

3. Indicator plate

4. Main frame

1

2

3

4

003710

Width of workpiece being cut

Less than 150 mm (5-7/8”)

150 mm (5-7/8”) - 240 mm (9-1/2”)

240 mm (9-1/2”) - 304 mm (12”)

Maximum depth of cut

3.0 mm (1/8”)

1.5 mm (1/16”)

1.0 mm (3/64”)

003711

1. Depth gauge

1

003712