15

Installing or removing socket

To install the socket, push it onto the anvil of the tool until it

locks into place.

To remove the socket, simply pull it off.

OPERATION

[*1] Presetting number of impacts is impossible for more than

200 impacts (4 seconds).

[*2] Fastening time includes when you pull the trigger com-

pletely.

CAUTION:

• Hold the tool firmly and place the socket over the bolt or

nut. Turn the tool on and fasten for the proper fastening

time and number of impacts (presetting number).

• If the tool is operated continuously until the battery

cartridge has discharged, allow the tool to rest for 15

minutes before proceeding with a fresh battery.

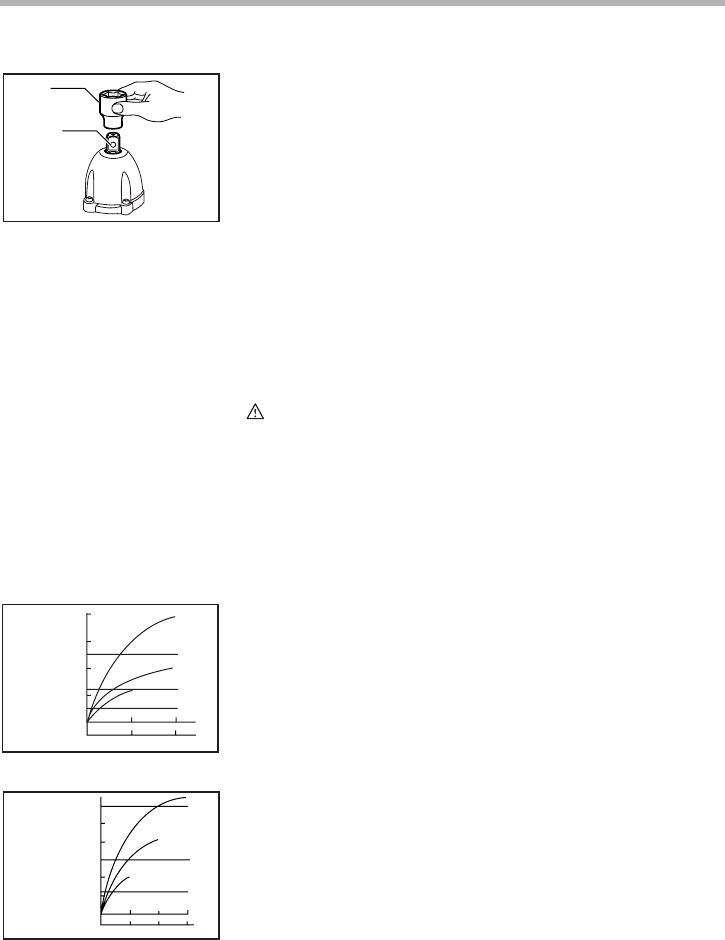

The proper fastening torque may differ depending upon the

kind or size of the bolt, the material of the workpiece to be

fastened, etc. The relation between fastening torque and fas-

tening time is shown in the figures.

NOTE:

• When fastening screw M8 (5/16”) or smaller, carefully

adjust pressure on the switch trigger so that the screw is

not damaged.

• Hold the tool pointed straight at the bolt or nut without

applying excessive pressure on the tool.

• Excessive fastening torque may damage the bolt/nut or

socket. Before starting your job, always perform a test

operation to determine the proper fastening time for your

bolt or nut. Especially for the bolt smaller than M8

(5/16”), perform the above test operation to prevent the

trouble on socket or bolt, etc.

The fastening torque is affected by a wide variety of factors

including the following. After fastening, always check the

torque with a torque wrench.

1. Socket

2. Anvil

2

1

001265

001274

M8 (5/16”)

M6 (1/4”)

0.5

40

(29)

30

(21)

20

(14)

10

(7)

0

1.0

(S)

25

(13)

50

(25)

*1

(*2)

N·m

(ft·lbs)

(M8)

(M10)

(M6)

M10 (3/8”)

Standard

bolt

*1 Number of impacts

*2 Dial setting

001275

M8 (5/16”)

1.0

40

(29)

30

(21)

20

(14)

10

(7)

0

2.0

50

(25)

100

(50)

3.0

150

(75)

N·m (ft·lbs)

(S)

*1

(*2)

(M8)

(M6)

50

(36)

60

(43)

M10 (3/8”)

(M10)

M6 (1/4”)

High tensile

bolt

*1 Number of impacts

*2 Dial setting