8

installation bolts with the socket wrench. The drum

cover comes off together with the blades. (Fig. 7)

2. To install the blades, loosely attach the adjusting plate

to the set plate with the pan head screws and set the

mini planer blade on the gauge base so that the

cutting edge of the blade is perfectly flush with the

inside flank of the gauge plate. (Fig. 8)

3. Set the adjusting plate/set plate on the gauge base so

that the planer blade locating lugs on the set plate rest

in the mini planer blade groove, then press in the heel

of the adjusting plate flush with the back side of the

gauge base and tighten the pan head screws.

4. It is important that the blade sits flush with the inside

flank of the gauge plate, the planer blade locating lugs

sit in the blade groove and the heel of the adjusting

plate is flush with the back side of the gauge base.

Check this alignment carefully to ensure uniform

cutting.

5. Slip the heel of the adjusting plate into the groove of

the drum.

6. Set the drum cover over the adjusting plate/set plate

and screw in the three hex flange head bolts so that a

gap exists between the drum and the set plate to slide

the mini planer blade into position. The blade will be

positioned by the planer blade locating lugs on the set

plate. (Fig. 9)

7. The blade’s lengthwise adjustment will need to be

manually positioned so that the blade ends are clear

and equidistant from the housing on one side and the

metal bracket on the other.

8. Tighten the three hex flange head bolts (with the

socket wrench provided) and rotate the drum to check

clearances between the blade ends and the tool body.

9. Check the three hex flange head bolts for final

tightness.

10. Repeat procedures 1 - 9 for other blade.

For the correct planer blade setting

Your planing surface will end up rough and uneven,

unless the blade is set properly and securely. The blade

must be mounted so that the cutting edge is absolutely

level, that is, parallel to the surface of the rear base.

Refer to some examples below for proper and improper

settings.

(A) Front base (Movable shoe)

(B) Rear base (Stationary shoe)

EN0004-1

Change of chip discharge direction

(Fig. 10)

Chip discharge direction can be changed to the right or

left. To change the direction, pull out the stopper while

turning it slightly backward and fit in it in one of two

openings on the opposite side of chip discharge so that

the recessed part fits to protrusion. (Fig. 11)

Dust bag (accessory) (Fig. 12)

Attach the dust bag onto the chip discharge opening.

The chip discharge opening is tapered. When attaching

the dust bag, push it onto the chip discharge opening

firmly as far as it will go to prevent it from coming off

during operation.

When the dust bag is about half full, remove the dust bag

from the tool and pull the fastener out. Empty the dust bag

of its contents, tapping it lightly so as to remove particles

adhering to the insides which might hamper further

collection. (Fig. 13)

NOTE:

• If you connect a Makita vacuum cleaner to this tool,

more efficient and cleaner operations can be

performed.

Connecting a vacuum cleaner (Fig. 14)

When you wish to perform clean planing operation,

connect a Makita vacuum cleaner to your tool. Then

connect a hose of the vacuum cleaner to the chip

discharge opening as shown in the figures.

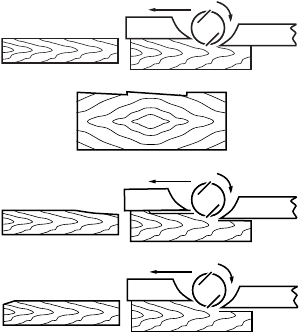

Correct setting Although this side view cannot show it, the

edges of the blades run perfectly parallel to

the rear base surface.

Nicks in surface Cause: One or both blades fails to have edge

parallel to rear base line.

Gouging at start Cause: One or both blade edges fails to

protrude enough in relation to rear

base line.

Gouging at end Cause: One or both blade edges protrudes

too far in relation to rear base line.

(A)

(B)

(B)

(A)

(A)

(B)