9

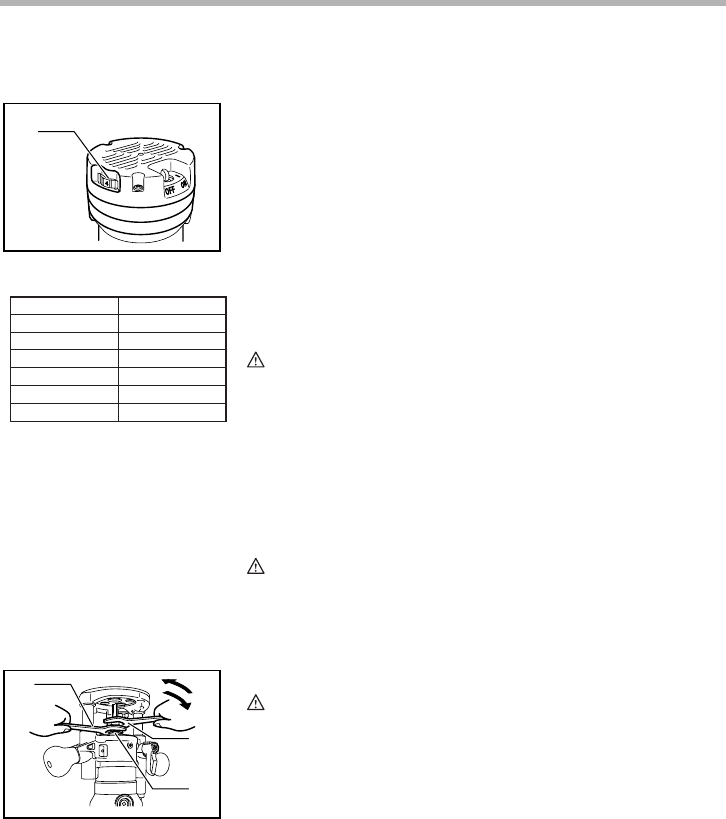

Speed adjusting dial

For model RP1101 only

The tool speed can be changed by turning the speed adjust-

ing dial to a given number setting from 1 to 6.

Higher speed is obtained when the dial is turned in the direc-

tion of number 6. And lower speed is obtained when it is

turned in the direction of number 1.

This allows the ideal speed to be selected for optimum mate-

rial processing, i.e. the speed can be correctly adjusted to

suit the material and bit diameter.

Refer to the table for the relationship between the number

settings on the dial and the approximate tool speed.

CAUTION:

• If the tool is operated continuously at low speeds for a

long time, the motor will get overloaded, resulting in tool

malfunction.

• The speed adjusting dial can be turned only as far as 6

and back to 1. Do not force it past 6 or 1, or the speed

adjusting function may no longer work.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Installing or removing the bit

CAUTION:

• Use always a collet which is suitable for the shank

diameter of the bit.

• Do not tighten the collet chuck without inserting a bit, or

the collet chuck will break.

• When using bit of bigger than 1-1/4” in diameter, install

base plate with center hole diameter 2-1/2”, replacing

the original base plate.

1. Speed adjusting dial

1

003666

Number

1

2

3

4

5

6

RPM

8,000

10,000

14,000

18,000

22,000

24,000

1. Wrench

2. Collet chuck

1

1

2

003671