19

ENGLISH

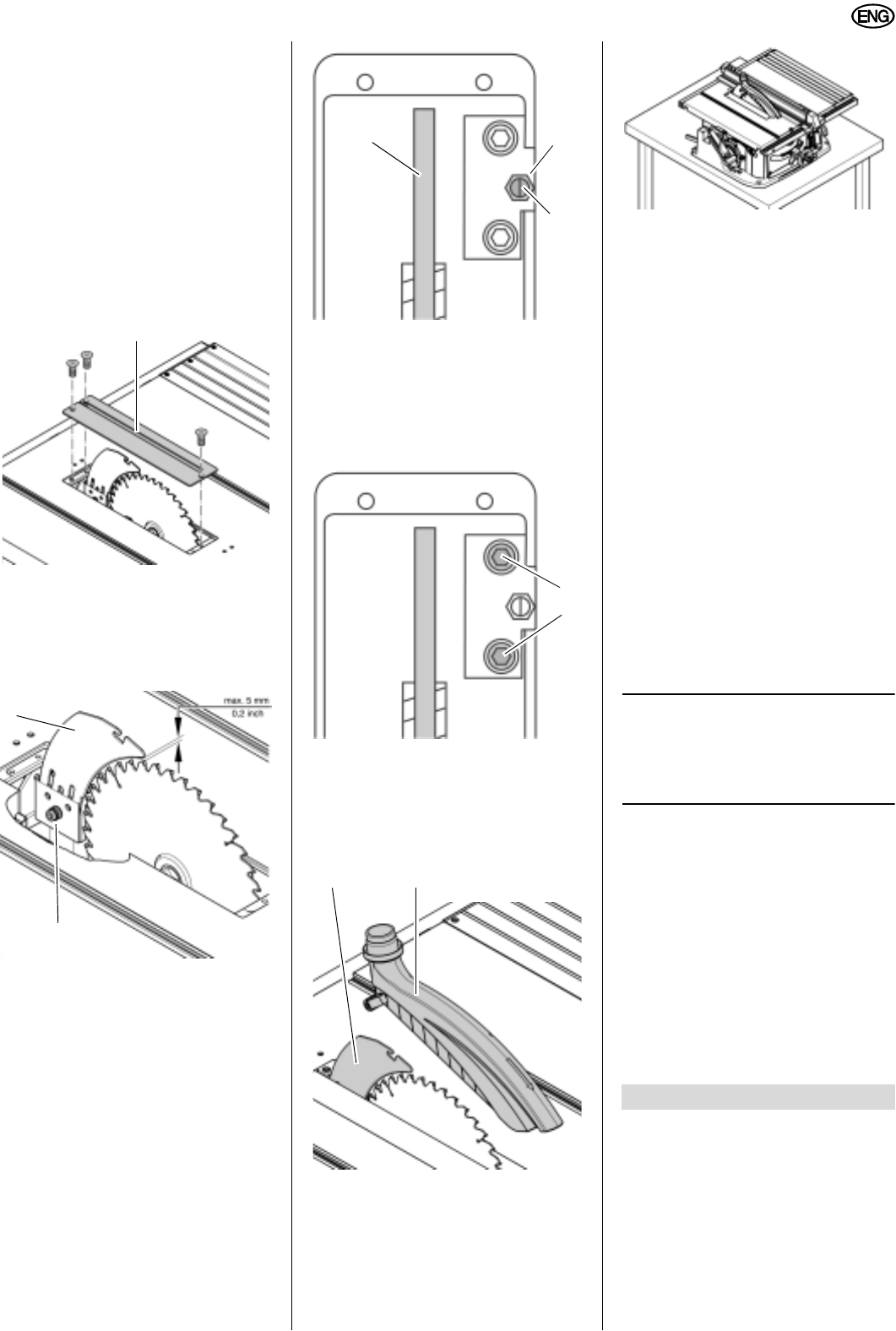

Distance between the saw

blade's outer edge and the riving

knife needs to be 3 – 5 mm.

The riving knife must be in align-

ment with the saw blade.

A

Danger!

The riving knife is one of the

safety devices and must be correctly

installed for safe operation.

Only if realignment of the riving knife is

necessary:

3. Loosen table insert (49) and remove

from table.

Setting the distance to the saw blade:

4. Loosen hexagon socket head cap

screw (50) (to do so, turn hexagon

socket head cap screw counter-

clockwise!)

5. Pull riving knife (51) fully up against

the stop and align: the gap between

saw blade and riving knife must be 3

to 5 mm.

6. Tighten hexagon socket head cap

screw (50) (to do so, turn hexagon

socket head cap screw clockwise!)

Lateral alignment:

riving knife and saw blade (52) must be

in true alignment.

7. Loosen hexagon nut (53) and adjust

vertical alignment with machine

screw (54).

8. Lock machine screw with (53).

9. Loosen both hexagon socket screws

(55).

10. Align riving knife flush with the saw

blade.

11. Tighten both hexagon socket

screws (55).

12. Reinstall table insert.

Blade guard installation

1. Raise saw blade fully.

2. Install blade guard (57) on riving

knife (56).

7.2 Installation

There are two ways to ensure a firm

stand of the machine:

mounted on floor stand

(accessory);

mounted on sturdy table or bench.

7.3 Mains connection

B

Danger! High voltage

x Operate this machine in dry sur-

roundings only.

x Operate machine only on a power

source meeting the following

requirements (see also “Techni-

cal Specifications”):

outlets properly installed,

earthed, and tested.

mains voltage and system fre-

quency conform to the voltage

and frequency shown on the

machine´s rating label;

fuse protection by a residual

current operated device (RCD)

of 30 mA sensitivity;

System impedance Z

max

at the

interconnection point (house

service connection) 0.35 Ohm

maximum.

3

Note:

Check with your local Electricity

Board or electrician if in doubt whether

your house service connection meets

these requirements.

x Position power supply cable so it

does not interfere with the work

and is not damaged.

x Protect power supply cable from

heat, aggressive liquids and

sharp edges.

x Use only rubber-jacketed exten-

sion cables with sufficient lead

cross-section (see “Technical

Specifications”).

x Do not pull on power supply

cable to unplug.

A

Risk of injury!

This saw may only be operated

by one person at a time. Other per-

sons shall stay only at a distance to

the saw for the purpose of feeding or

removing stock.

Before starting work, check to see

that the following are in proper work-

ing order:

power cable and plug;

49

50

51

52

53

54

55

56 57

8. Operation