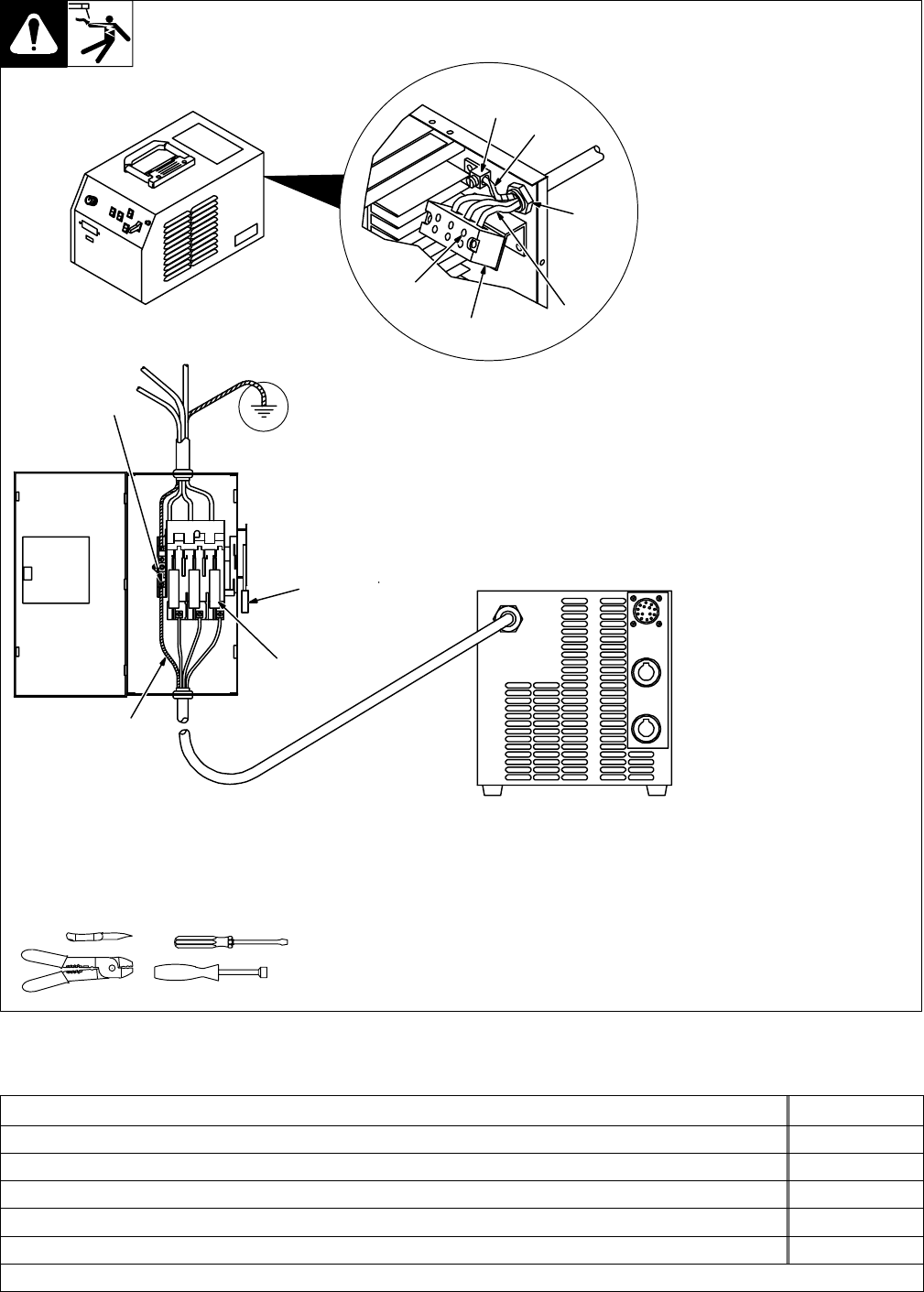

OM-206 Page 14

Have only qualified persons make

this installation.

1 Line Disconnect Device Of

Proper Rating

2 Input Conductors

3 Grounding Conductor

Select size and length using Sec-

tion 3-10. Conductor rating must

comply with national, state, and

local electrical codes. Strip 3/8 in

(10 mm) insulation off conductors.

4 Strain Relief Connector

Remove wrapper and insert con-

ductors.

5 Input Terminal Block

6 Line Terminals

7 Welding Power Source

Ground Terminal

Connect grounding conductor to

ground terminal first. Then connect

input conductors to line terminals.

Tighten strain relief connector.

8 Disconnect Device Ground

Terminal

Install and connect grounding

conductor and input conductors in

conduit or equivalent to deener-

gized line disconnect device.

Connect grounding conductor first,

then line input conductors. Be sure

grounding conductor goes to an

earth ground.

Reinstall wrapper.

9 Overcurrent Protection

Select type and size using Section

3-10. Install into deenergized line

disconnect device (fused

disconnect switch shown).

ssb2.4* 1/94 – ST-145 667-B / SA-145 666-C

7

3

4

2

5

1

9

Tools Needed:

5/16 in

6

3

8

3-9. Connecting Input Power To 175 Models

3-10. Electrical Service Guide For 175 Ampere Models

Input Voltage

460

Input Amperes At Rated Output

7.4

Max Recommended Standard Fuse Or Circuit Breaker Rating In Amperes

10

Min Input Conductor Size In AWG/Kcmil

14

Max Recommended Input Conductor Length In Feet (Meters)

443 (135)

Min Grounding Conductor Size In AWG/Kcmil

14

Reference: 1993 National Electrical Code (NEC). S-0092J