OM-4428 Page 27

5-9. Connecting To Weld Output Terminals

803 602 / 803 778-A

Tools Needed:

2

3/4 in

1

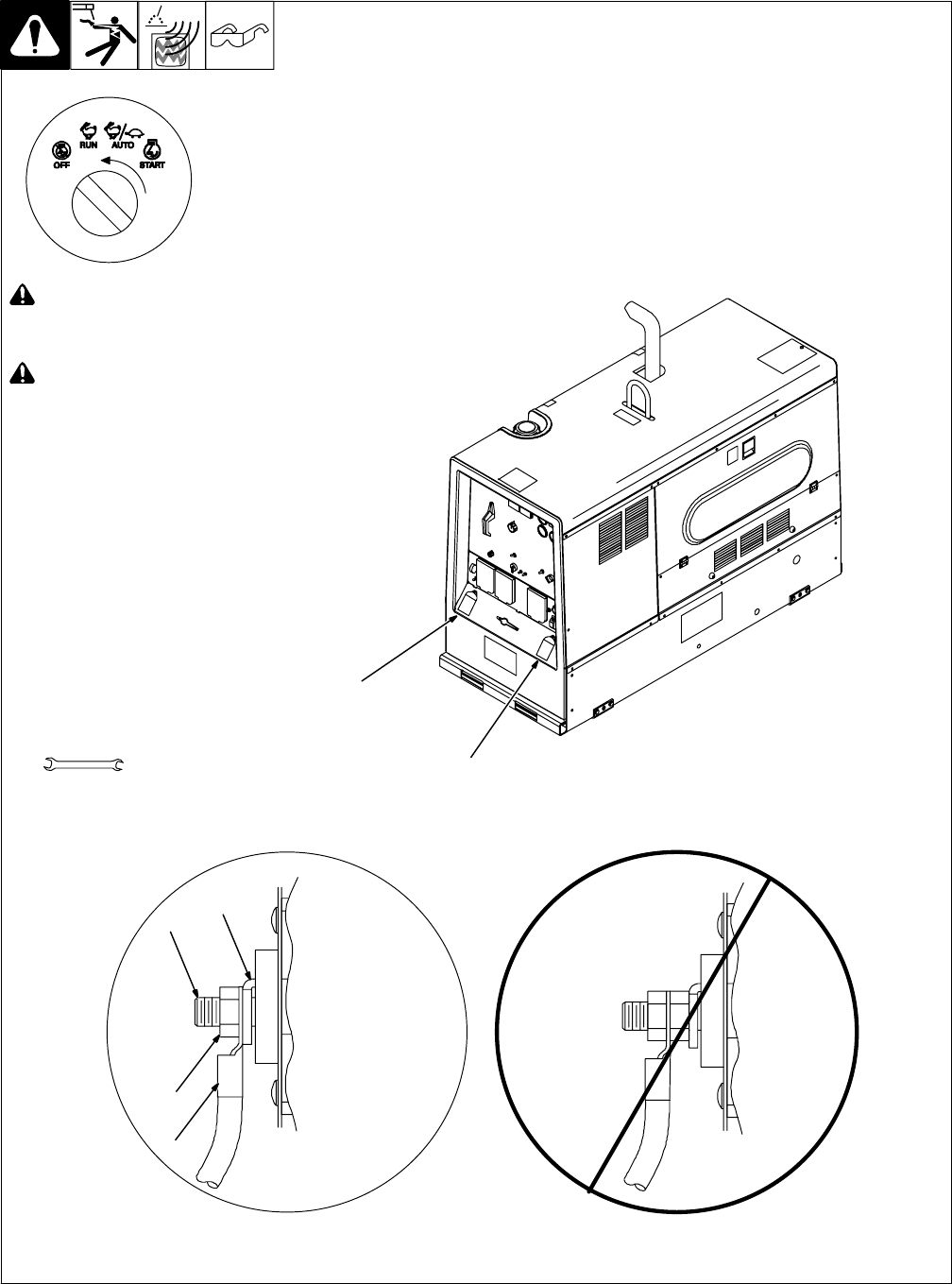

MIG and FCAW Welding

For MIG and FCAW welding Direct Current

Electrode Positive (DCEP) on CC/CV models,

connect wire feeder cable to Positive (+) termi-

nal on left and work cable to Negative (−) ter-

minal on right. Use Process/Contactor switch

to select type of weld output (see Section 7-3).

For Direct Current Electrode Negative

(DCEN), reverse cable connections.

If equipped with optional Polarity switch or op-

tional Polarity/AC switch, connect wire feeder

cable to Electrode (+) terminal on left and

work cable to Work (−) terminal on right.

6

4

5

Do not place

anything between

Correct Installation

Incorrect Installation

3

weld cable terminal

and copper bar.

! Stop engine.

1 Positive (+) Weld Output Terminal

2 Negative (−) Weld Output Terminal

! Failure to properly connect weld

cables may cause excessive heat and

start a fire, or damage your machine.

3 Weld Output Terminal

4 Supplied Weld Output Terminal Nut

5 Weld Cable Terminal

6 Copper Bar

Remove supplied nut from weld output termi-

nal. Slide weld cable terminal onto weld output

terminal and secure with nut so that weld cable

terminal is tight against copper bar. Do not

place anything between weld cable termi-

nal and copper bar. Make sure that the sur-

faces of the weld cable terminal and cop-

per bar are clean.

Stick and TIG Welding

For Stick and TIG welding Direct Current Elec-

trode Positive (DCEP), connect electrode

holder cable to Positive (+) terminal on left and

work cable to Negative (−) terminal on right.

For Direct Current Electrode Negative

(DCEN), reverse cable connections.

If equipped with optional Polarity switch or op-

tional Polarity/AC switch, connect electrode

holder cable to Electrode (+) terminal on left

and work cable to Work (−) terminal on right.