OM-477 Page 29

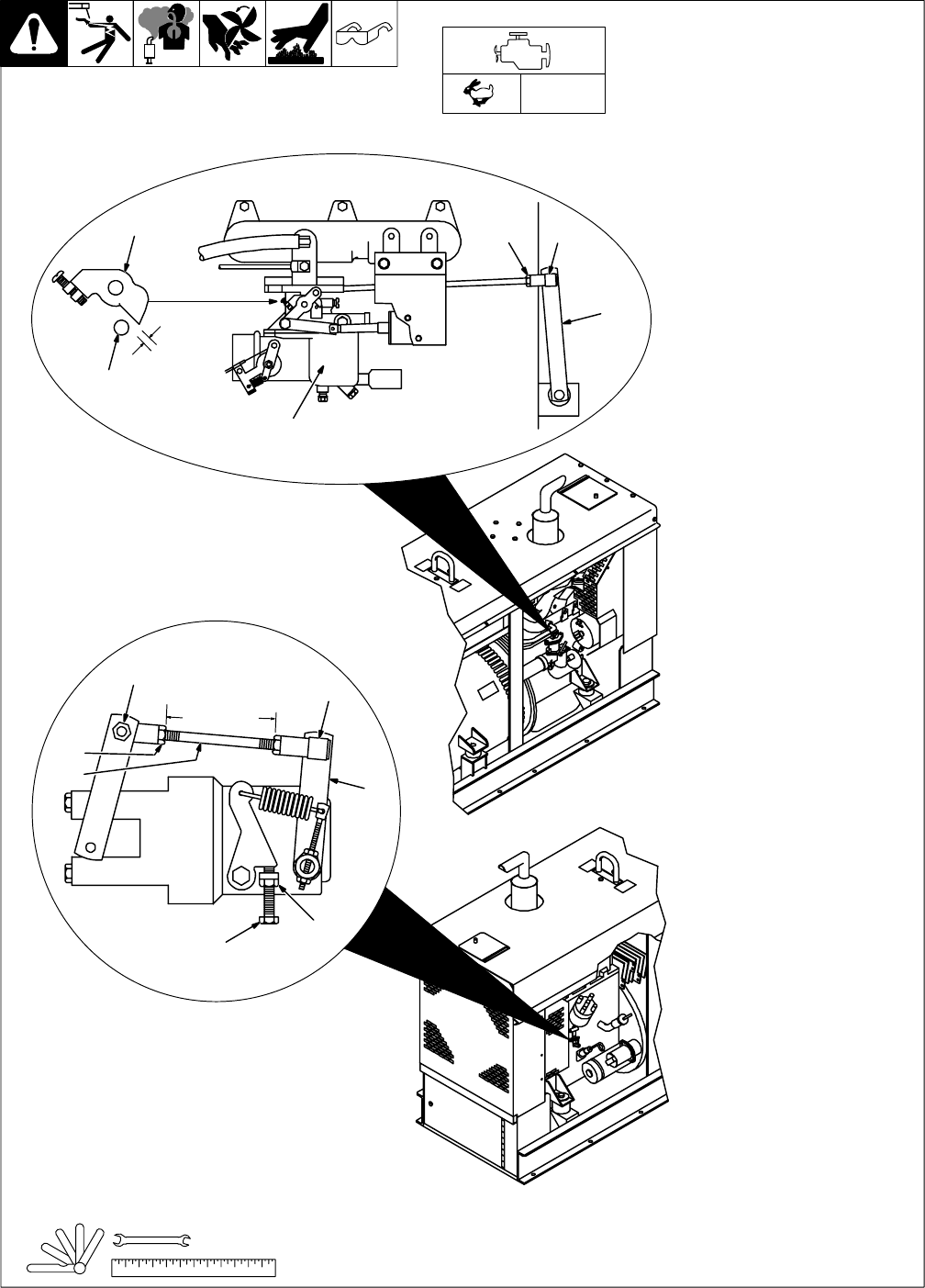

7-8. Adjusting Engine Weld/Power Speed

Ref. ST-801 179 / Ref. ST-800 159-C / Ref. ST-800 161

. Governor sensitivity may re-

quire adjustment if engine

speed is adjusted (see Section

7-10).

If linkage binds, loosen socket

nuts and turn sockets until link-

age works smoothly. Tighten

nuts.

After tuning engine, check engine

no load speed with a tachometer

(see table for no load speeds). If

necessary, adjust speed as follows:

1 Socket Nut

2 Governor Linkage Rod

3 Lock Nut

4 Socket

5 Governor Arm

Rod length should be 3-1/4 in (83

mm) between lock nuts. To adjust,

remove socket from arm and loos-

en lock nut. Turn socket to adjust

length. Tighten nut and reattach

socket to arm.

6 Carburetor

7 Throttle Stop Plate

8 Throttle Stop

Clearance between plate and stop

should be 1/16 in (1.6 mm). To ad-

just clearance, proceed as follows:

9 Linkage Pivot Arm

10 Linkage Socket

11 Lock Nut

Remove socket at arm and loosen

lock nut. Turn socket to adjust

clearance. Reattach socket and

tighten nut.

Start engine and run until warm.

Turn Engine Control switch to Run

position.

12 Governor Speed Screw

13 Lock Nut

Loosen nut. Turn screw until engine

runs at weld/power speed.

Y Stop engine.

Close door.

Tools Needed:

3/8, 7/16 in

1850 rpm

(max)

2

3

4

5

6

7

8

9

1011

12

13

3-1/4 in

(83 mm)

1/16 in

(1.6 mm)

1