OM-477 Page 30

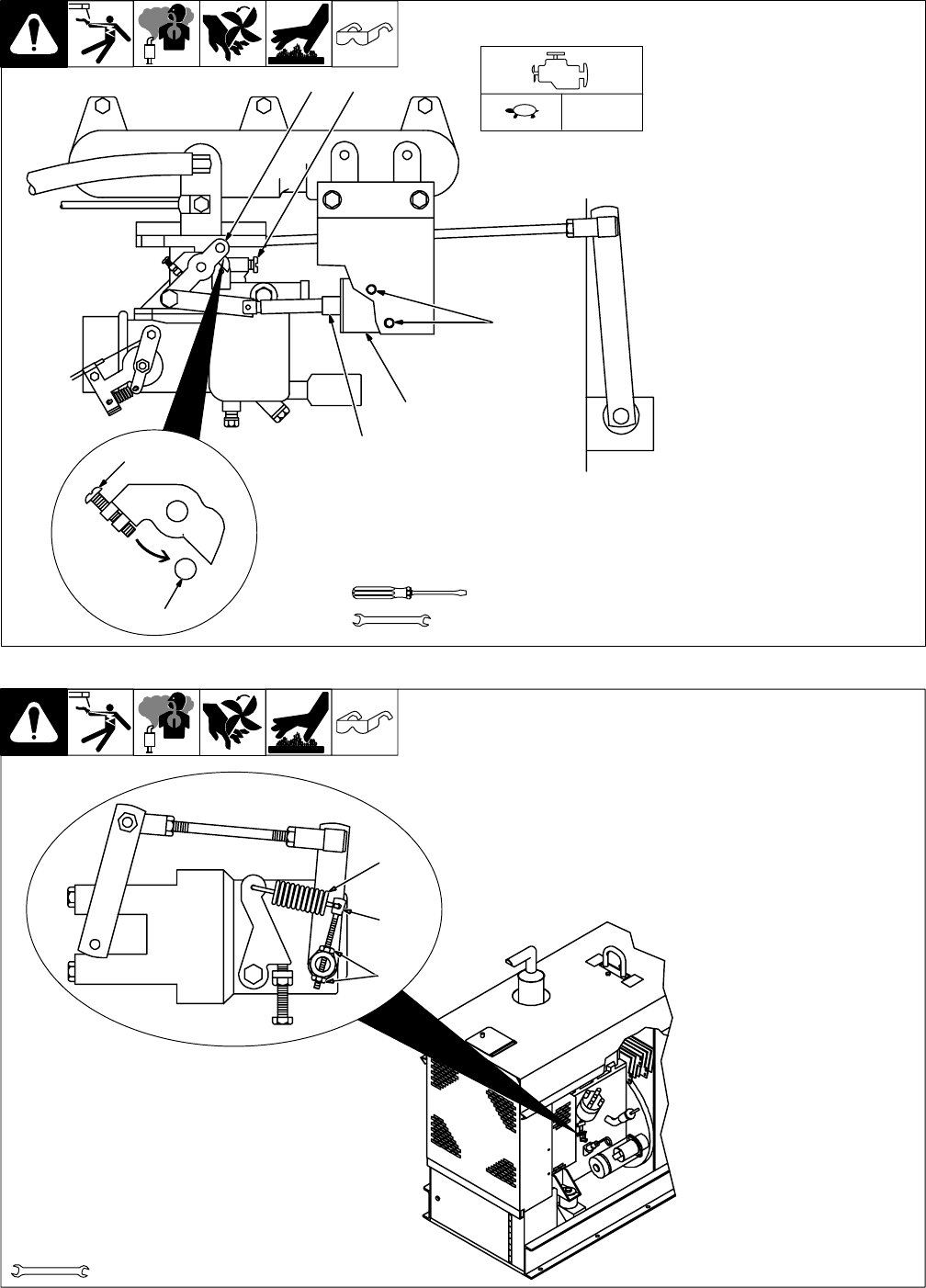

7-9. Adjusting Engine Idle Speed

Ref. ST-115 155-A

Start engine. Place Engine Control

Switch in Run/Idle position.

1 Solenoid Bracket Screws

2 Throttle Arm

3 Idle Speed Screw

4 Throttle Stop

Loosen bracket screws and move

arm so screw touches stop. Do not

release arm. Turn idle speed screw

to obtain 550 rpm.

5 Idle Mixture Screw

Turn mixture screw counterclock-

wise until engine falters, then turn

screw clockwise until engine runs

smoothly.

Turn idle speed screw to obtain

1250 rpm.

6 Solenoid

7 Plunger

Slide solenoid inside bracket so

plunger bottoms in solenoid. If nec-

essary, shim solenoid/bracket to

prevent linkage from binding. Do

not readjust idle speed screw when

adjusting solenoid.

Tighten bracket screws. Release

throttle arm. Recheck idle speed

and readjust if necessary.

Y Stop engine.

Close door.

Tools Needed:

1

2

3

4

5

6

7

Right Side

1/4 in

1250 rpm

7-10. Adjusting Governor Sensitivity

Ref. ST-115 155-A / Ref. ST-159 728-A

. Governor sensitivity may re-

quire readjustment if weld

speed is adjusted. Weld speed

must be readjusted if sensitivity

is adjusted.

Be sure carburetor and link-

ages are adjusted properly be-

fore adjusting sensitivity.

Start engine. Apply and remove

load.

1 Locking Nuts

2 Sensitivity Adjustment Screw

3 Governor Spring

If engine is slow to pick up load or

rpm drops under load, adjust spring

tension as follows:

Loosen top nut and tighten bottom

nut to move screw down. Tighten

nuts.

If engine hunts with or without load,

adjust spring tension as follows:

Loosen bottom nut and tighten top

nut to move screw up. Tighten nuts.

Y Stop engine.

Close door.

Tools Needed:

1/2 in

3

2

1