OM-4433 Page 39

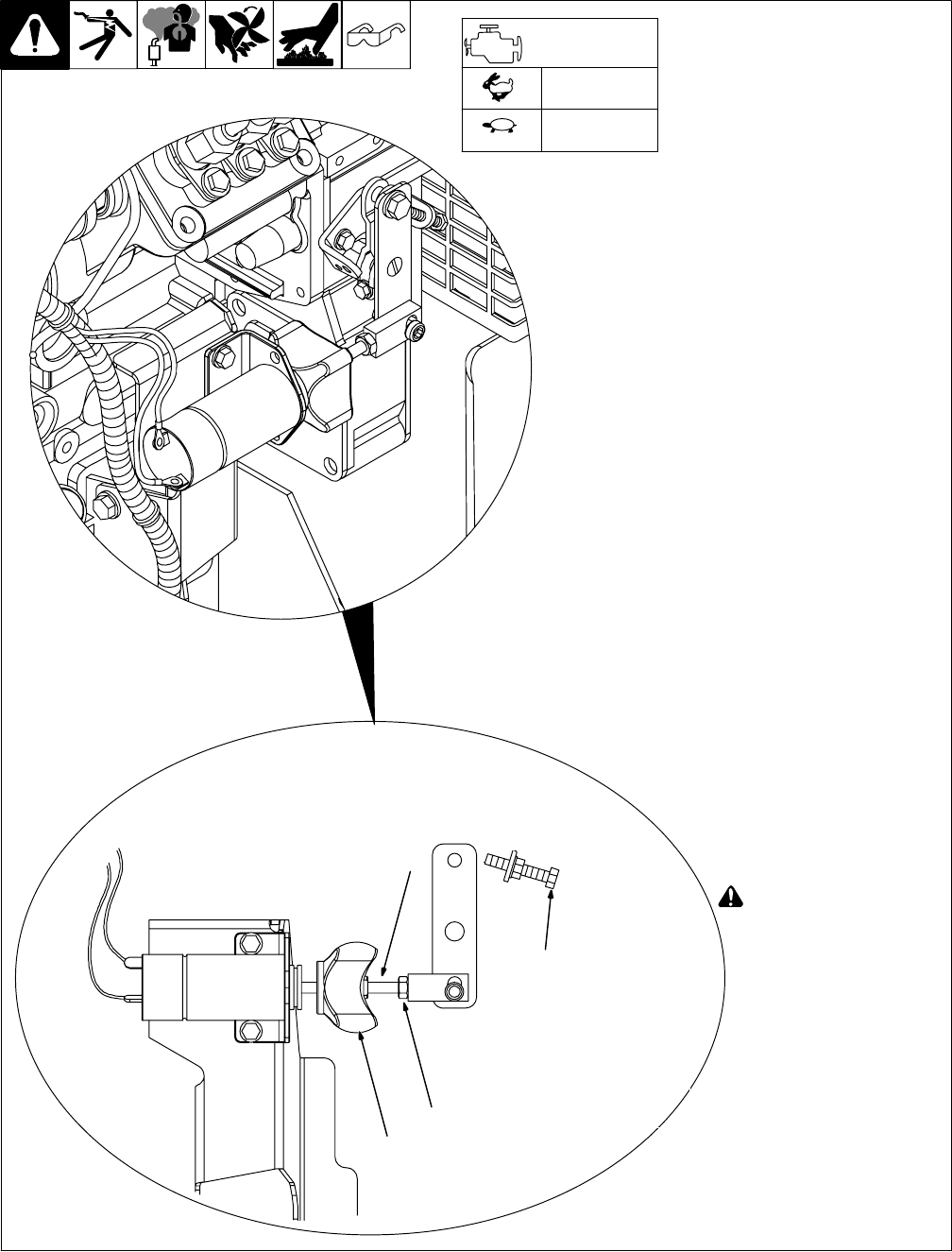

8-7. Adjusting Engine Speed On Models With Automatic Idle (Optional)

803 563-G

1880 rpm max

(62.6 Hz)

1500 rpm

(50 Hz)

Engine Speed

(No Load)

1

2

3

4

. To prevent solenoid

damage, be sure a 1/8

in (3 mm) gap exists be-

tween the engine low

speed screw and

throttle lever when the

solenoid is held in the

energized position.

Engine Speed Adjustment

After tuning engine, check en-

gine speed with tachometer or

frequency meter. See table for

proper no load speed. If neces-

sary, adjust speed as follows:

Start engine and run until warm.

Turn Process/Contactor switch

to Stick − Weld Terminals Al-

ways On position.

1 Throttle Rod / Plunger

2 Lock Nut

3 Rubber Boot

4 Adjustment Screw

Adjustment screw is not used to

adjust engine speed when auto-

matic idle option is installed.

However, it must be at least 1/8

in (3 mm) away from the throttle

arm when engine is running at

idle rpm.

Unhook rubber boot from the so-

lenoid housing but leave con-

nected to plunger.

Loosen lock nut. Place Engine

Control Switch in Auto position.

Turn throttle rod and plunger un-

til engine runs at idle speed.

Tighten lock nut.

Hook rubber boot back onto so-

lenoid housing.

. Be sure solenoid plunger

pulls all the way in (“bot-

toms”) when energized.

Weld/Power Speed

Adjustment

. Weld/power speed adjust-

ment must be done by the

engine manufacturer’s fac-

tory authorized service

agent.

Tampering with adjustments

other than shown may affect

engine warranty.

! Stop engine.