OM-4433 Page 40

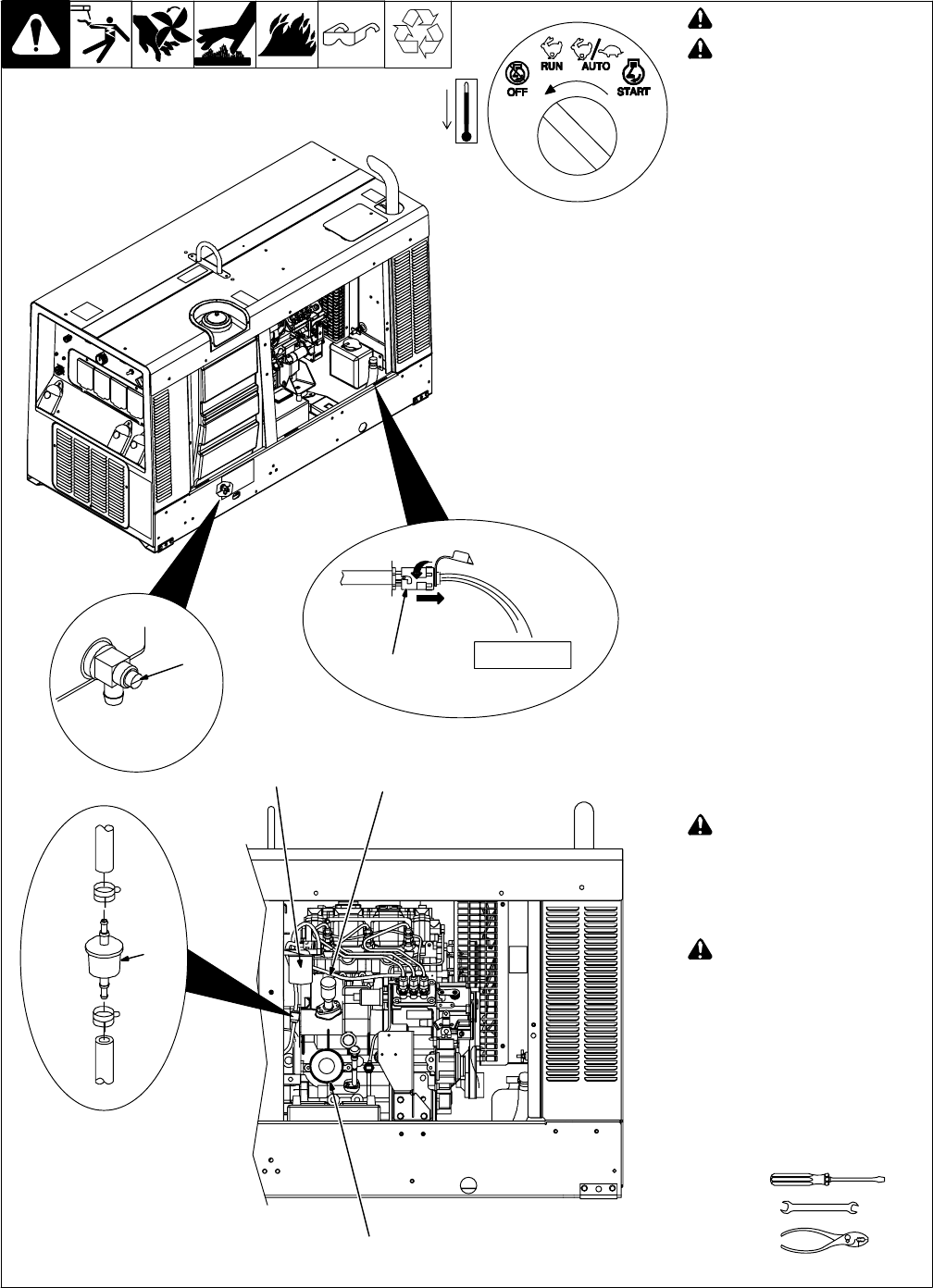

8-8. Servicing Fuel And Lubrication Systems

802 490 / Ref. 801 434

! Stop engine and let cool.

! After servicing, start engine

and check for fuel leaks.

Stop engine, tighten connec-

tions as necessary, and wipe

up spilled fuel.

1 Oil Filter

2 Oil Drain Valve And Hose

3 Oil Fill Cap

4 Primary (Canister) Fuel Filter

5 Secondary (In-Line) Fuel

Filter

6 Fuel Tank Sludge Drain Valve

To change oil and filter:

Route oil drain hose and valve

through hole in base. See engine

manual and engine maintenance

label for oil/filter change in-

formation.

To replace primary (canister) fuel

filter:

Turn filter counterclockwise. Re-

move filter.

Fill new filter with fresh fuel. Apply

thin coat of fuel to gasket on new fil-

ter. Install new filter and turn clock-

wise.

Inspect fuel lines, and replace if

cracked or worn.

To drain water from fuel system:

See engine manual.

To replace secondary (in-line)

fuel filter:

Note direction of fuel flow as indi-

cated by arrow on side of filter. Re-

move fuel line clamps and discon-

nect fuel lines from fuel filter. Re-

place filter, reconnect fuel lines, and

reinstall clamps.

To drain sludge from fuel tank:

! Beware of fire. Do not smoke

and keep sparks and flames

away from drained fuel. Dis-

pose of drained fuel in an en-

vironmentally-safe manner.

Do not leave unit unattended

while draining fuel tank.

! Properly lift unit and secure

in a level position. Use ade-

quate blocks or stands to

support unit while draining

fuel tank.

Attach 1/2 ID hose to drain valve.

Put metal container under drain,

and use screwdriver to open

sludge drain valve. Close valve

when sludge has drained. Remove

hose.

Close door.

Tools Needed:

6

3

5

2

4

1