OM-496 Page 47Return To Table Of Contents

9-6. Adjusting Engine Speed On Models With Automatic Idle (Optional)

802 490 / 802 538-A

After tuning engine, check engine

speed with tachometer or frequency

meter. See table for proper no load

speed. If necessary, adjust speed

as follows:

Start engine and run until warm.

On CC models, place Stick/TIG

switch in Stick position.

On CC/CV models, turn Process/

Contactor switch to Stick − Elec-

trode Hot position.

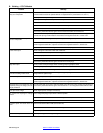

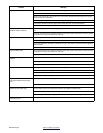

Idle Speed Adjustment

1 Throttle Rod/Plunger

2 Locknut

Loosen locknut. Place Engine Con-

trol switch in Run/Idle position.

Turn throttle rod and plunger until

engine runs at idle speed. Tighten

locknut.

. Be sure solenoid plunger pulls

all the way in (“bottoms”) when

energized.

. If necessary, move linkage to

other hole in bracket or move

cotter pin to other hole in throttle

arm to set idle speed correctly.

Weld/Power Speed Adjustment

3 Engine Weld/Power Speed

Adjustment Screw

4 Locknut

Place Engine Control switch in Run

position.

Loosen locknut. Turn screw until en-

gine runs at weld/power speed.

Tighten locknut.

. Do not set engine speed higher

than specified.

Y Stop engine.

1850 rpm max

(61.6 Hz)

1250 rpm

(41.6 Hz)

Engine Speed

(No Load)

2

1

4

3

If necessary, move

linkage to other hole in

bracket or move cotter

pin to other hole in

throttle arm to set idle

speed correctly.