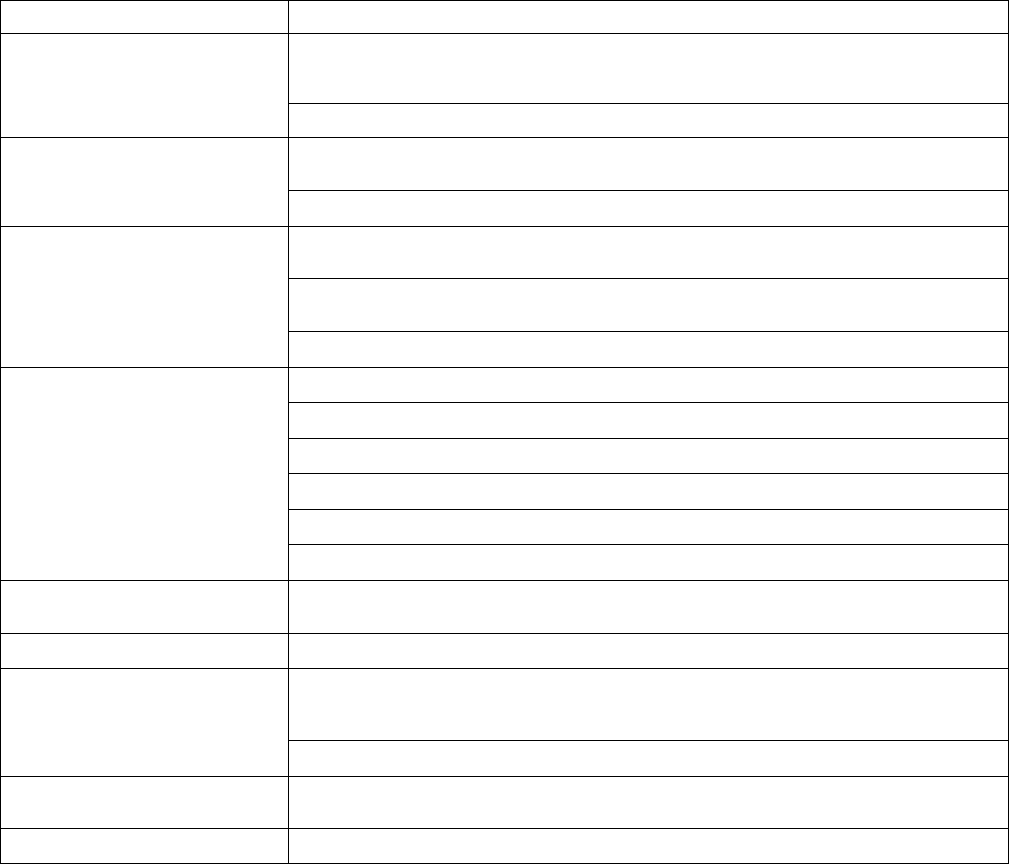

OM-197 509 Page 15

Trouble Remedy

Fan in welding power source not oper-

ating. Note: fan runs only when cool-

ing is necessary.

Check for and remove anything blocking fan movement.

Have Factory Authorized Service Agent check fan motor.

Wire does not feed, unit completely

inoperative.

Check 10–pin plug PLG8 connections (see Section 3-7).

Check input power.

Wire does not feed. Check circuit breaker CB2 on welding power source, and reset if necessary (see welding power source

owner’s manual).

Check gun trigger connection at wire feeder (see Section 3-9). Check gun trigger leads and trigger

switch.

Have Factory Authorized Service Agent check drive motor, control board PC1, and motor board PC2.

Wire feeds erratically. Readjust hub tension and drive roll pressure (see Section 3-11 and 3-12).

Use correct size drive roll (see Parts List).

Clean or replace dirty or worn drive roll (see 3-4 Section).

Remove weld spatter around nozzle opening.

Replace contact tip or liner.

Have Factory Authorized Service Agent check drive motor and control board PC1.

Wire feeds when Jog switch is pressed

but not when gun trigger is pressed.

Check gun trigger connection at wire feeder (see Section 3-9). Check gun trigger leads and trigger

switch.

Wire feeds as soon as power is applied. Check gun trigger.

Wire does not feed until trigger is

pressed, but continues to feed after

trigger is released.

Check position of Mode switch on welding power source. This is normal operation when switch is in

Crater Fill On or Trigger Hold On positions (see welding power source owner’s manual).

Check for short between gun trigger leads and weld cable. Repair or replace gun trigger leads.

Gas valve rattles loudly and wire feeds

slowly or erratically.

Check for short between gun trigger leads and weld cable. Repair or replace gun trigger leads.

Gas does not flow; wire feeds. Check gas valve and flowmeter.