. A complete Parts List is available at www.MillerWelds.com

OM-230 693 Page 29

SECTION 6 − MAINTENANCE &TROUBLESHOOTING

6-1. Routine Maintenance

! Disconnect power

before maintaining.

. Maintain more often

during severe conditions.

n = Check Z = Change ~ = Clean l = Replace

* To be done by Factory Authorized Service Agent

Reference

Every

3

Months

l Unreadable Labels ~ Weld Terminals nl Weld Cables

Every

6

Months

OR

~ Inside Unit n Apply Light Coat Of Oil

Or Grease To Drive Motor

Shaft

6-2. Unit Overload

Thermistor T in SCR1 protects the unit from damage due to overheating. If HL.P 002 is displayed on the meters, wait

for unit to cool allowing fan motor to run before trying to weld. If unit is cool and no weld output continues, contact

Factory Authorized Service Agent.

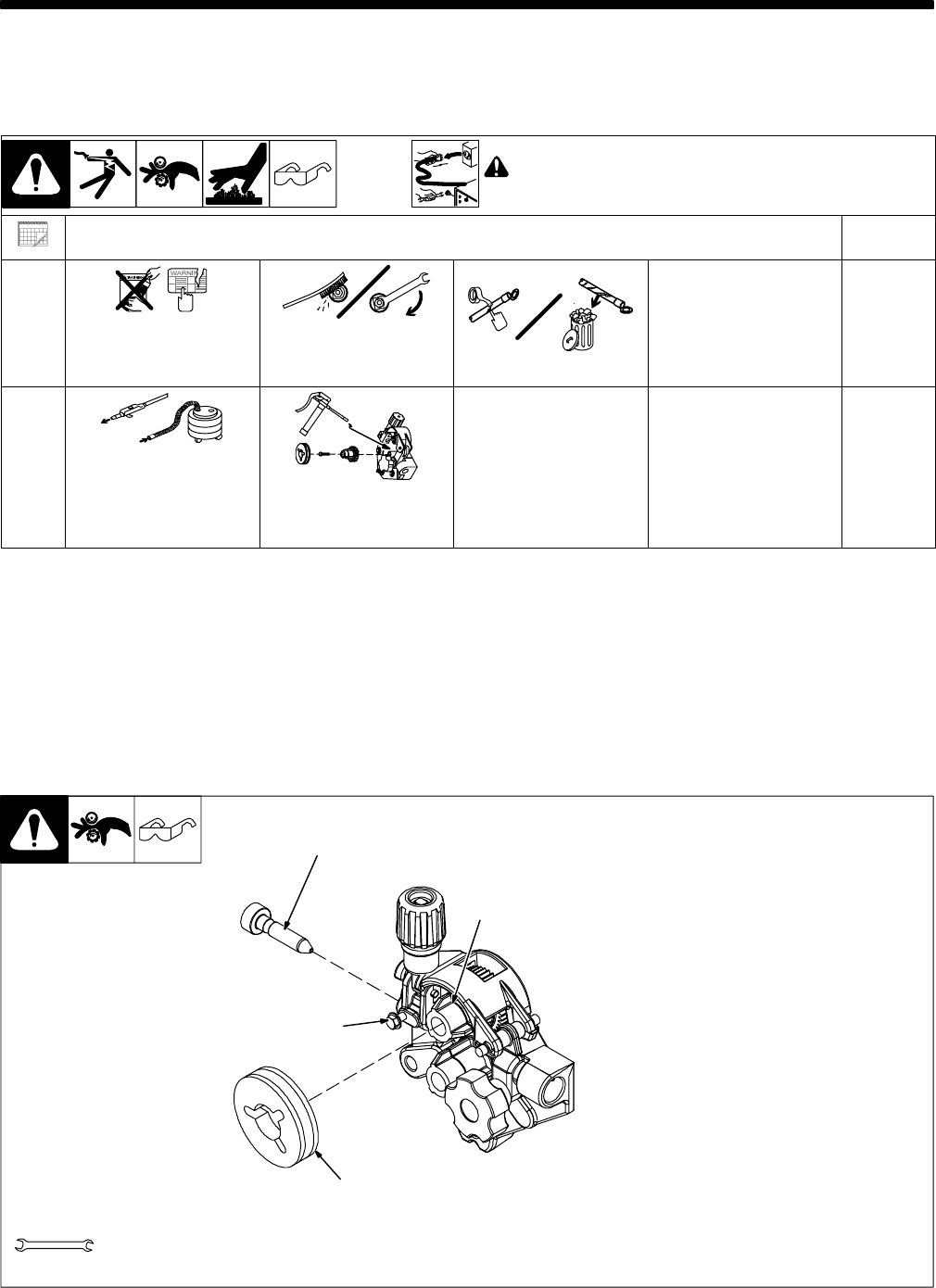

6-3. Changing Drive Roll and Wire Inlet Guide

1 Securing Screw

2 Inlet Wire Guide

Loosen screw. Slide tip as close to

drive rolls as possible without

touching. Tighten screw.

3 Drive Roll

The drive roll consists of two

different sized grooves. The

stamped markings on the end

surface of the drive roll refers to the

groove on the opposite side of the

drive roll. The groove closest to the

motor shaft is the proper groove to

thread (see Section 4-14).

4 Drive Roll Securing Nut

Turn nut one click to secure drive

roll.

Tools Needed:

7/16 in

1

2

3

4

Ref. 804 914-A