6

7

APPLICATIONS

WARNING To reduce the risk of elec-

tric shock, check work area for hidden pipes

and wires before drilling or driving screws.

Fig. 7

Push for

Forward

Push for

Reverse

PUSH TO CENTER TO LOCK

Fig. 4

To Hammer

Fig. 5

To Drill

Fig. 6

To Drive Screws

Torque

selector

collar setting

1 - 5

6 - 10

11 - 15

16 - 20

Drill

Low

High

0 - 17 in. lbs.

21 - 38 in. lbs.

42 - 60 in. lbs.

65 - 85 in. lbs.

460 in. lbs.

160 in. lbs.

0615-20

& 0617-20

Torque

0 - 17 in. lbs.

21 - 38 in. lbs.

42 - 60 in. lbs.

65 - 85 in. lbs.

495 in. lbs.

175 in. lbs.

0625-20

& 0627-20

Torque

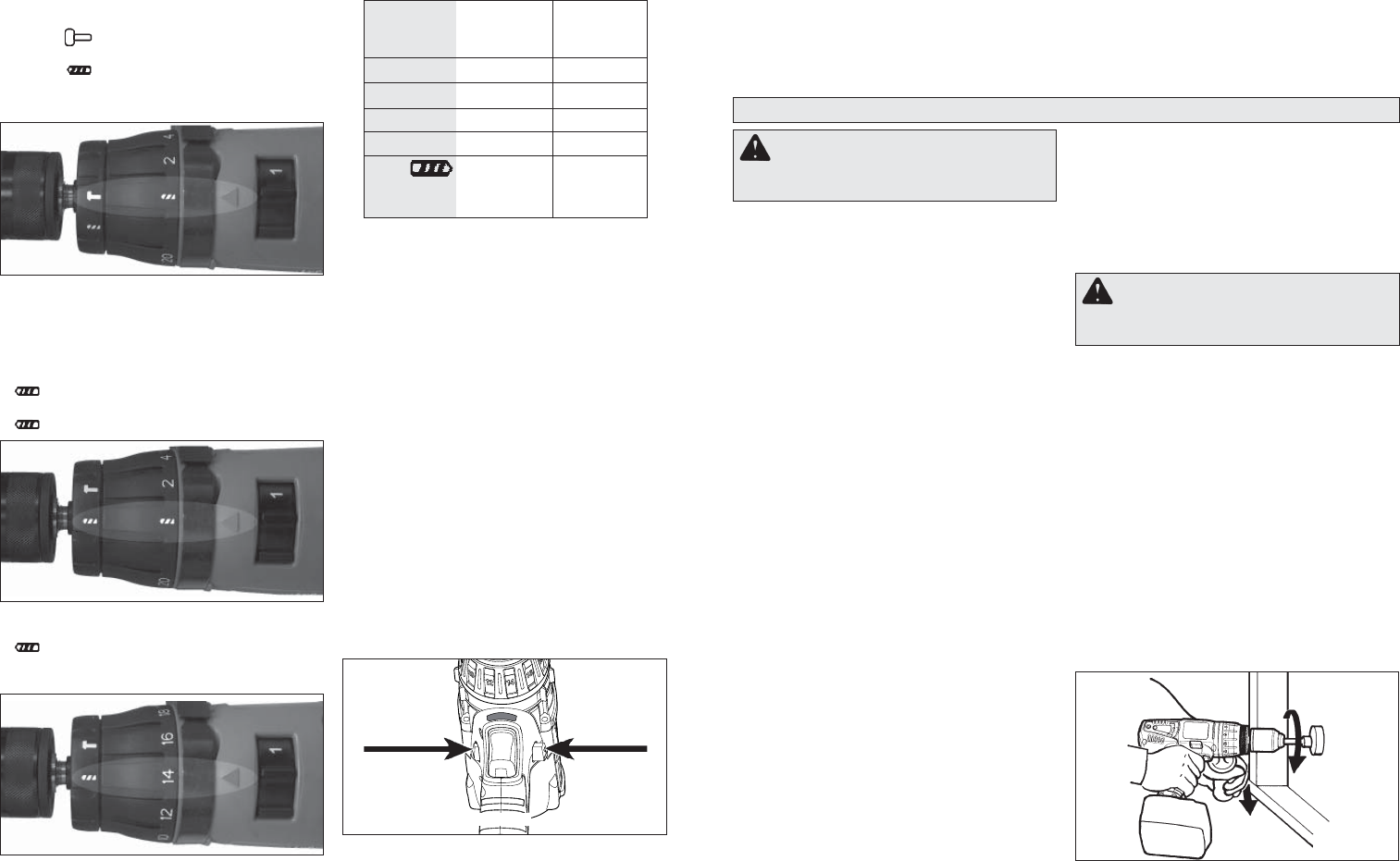

Selecting Hammer or Drill Action

MILWAUKEE Hammer-Drills are designed for three

operating modes: drilling with hammering action,

drilling only, and driving screws. To set the operating

mode, rotate the hammer/drill selector collar and

torque selector collar to the desired symbols.

1. To use the hammer-drilling mode, rotate the

hammer/drill selector collar until the hammer

symbol

appears in line with the arrow. Then

rotate the Torque selector collar until the drill

symbol appears in line with the arrow. Ap-

ply pressure to the bit to engage the hammering

mechanism.

NOTE: When using carbide bits, do not use water

to settle dust. Do not attempt to drill through steel

reinforcing rods. This will damage the carbide

bits.

2. To use the drilling only mode, rotate the

hammer/drill selector collar until the drill symbol

appears in line with the arrow. Then rotate

the Torque selector collar until the drill symbol

appears in line with the arrow.

3. To use the driving screws mode, rotate the

hammer/drill selector collar until the drill symbol

appears in line with the arrow. Then rotate

the torque selector collar until the desired clutch

setting appears in line with the arrow.

The adjustable clutch ,when properly adjusted,

will slip at a preset torque to prevent driving the

screw too deep into different materials and to

prevent damage to the screw or tool.

The torque specifi cations shown here are approxi-

mate values.

NOTE: Because the above settings are only a

guide, use a piece of scrap material to test the dif-

ferent clutch positions before driving screws into

the workpiece.

Using Control Switch

The control switch may be set to three positions:

forward, reverse and lock. Due to a lockout mecha-

nism, the control switch can only be adjusted when

the ON/OFF switch is not depressed. Always allow

the motor to come to a complete stop before using

the control switch.

For forward (clockwise) rotation, push in the control

switch from the right side of the tool. Check the

direction of rotation before use.

For reverse (counterclockwise) rotation, push in the

control switch from the left side of the tool. Check

direction of rotation before use.

To lock the trigger, push the control switch to the

center position. The trigger will not work while

the control switch is in the center locked position.

Always lock the trigger or remove the battery

pack before performing maintenance, changing

accessories, storing the tool and any time the tool

is not in use.

Starting, Stopping and Controlling Speed

1. To start the tool, grasp the handle fi rmly and

pull the trigger.

2. To vary the speed, increase or decrease the

pressure on the trigger. The further the trigger

is pulled, the greater the speed.

3. To stop the tool, release the trigger. Make sure

the bit comes to a complete stop before laying

the tool down.

Drilling

Set both the hammer/drill and torque selector col-

lars to the drill positions.

Place the bit on the work surface and apply fi rm

pressure before starting. Too much pressure will

slow the bit and reduce drilling effi ciency. Too little

pressure will cause the bit to slide over the work

area and dull the point of the bit.

If the tool begins to stall, reduce pressure slightly to

allow the bit to regain speed. If the bit binds, reverse

the motor to free the bit from the workpiece.

Drilling in Wood, Composition Materials and

Plastic

When drilling in wood, composition materials and

plastic, start the drill slowly, gradually increasing

speed as you drill. When drilling into wood, use

wood augers or twist drill bits. Always use sharp

bits. When using twist drill bits, pull the bit out of the

hole frequently to clear chips from the bit fl utes. To

reduce the chance of splintering, back work with a

piece of scrap wood. Select low speeds for plastics

with a low melting point.

Drilling in Metal

When drilling in metal, use high speed steel twist

drills or hole saws. Use a center punch to start the

hole. Lubricate drill bits with cutting oil when drilling

in iron or steel. Use a coolant when drilling in non-

ferrous metals such as copper, brass or aluminum.

Back the material to prevent binding and distortion

on breakthrough.

Drilling in Masonry

When drilling in masonry, select the hammer-drill

operating mode (hammer-drills only). Use high

speed carbide-tipped bits. Drilling soft masonry ma-

terials such as cinder block requires little pressure.

Hard materials like concrete require more pressure.

A smooth, even fl ow of dust indicates the proper

drilling rate. Do not let the bit spin in the hole without

cutting. Do not use water to settle dust or to cool

bit. Both actions will damage the carbide.

Driving Screws and Nut Running

Drill a pilot hole when driving screws into thick or

hard materials. Set the torque selector collar to the

proper position and set the speed to low. Use the

proper style and size screwdriver bit for the type

of screw you are using.

With the screwdriver bit in the screw, place the tip of

the screw on the workpiece and apply fi rm pressure

before pulling the trigger. Screws can be removed

by reversing the motor.

Overloading

Continuous overloading may cause permanent

damage to tool or battery pack.

Fig. 8

Reaction

Forward

rotation

Bracing

against the

fl oor

WARNING High rotational force. To

reduce the risk of injury, always hold or brace

securely. Always use side handle on tools.

Bit Binding

A high rotational force occurs when a bit binds. If

the bit binds, the tool will be forced in the opposite

direction of the bit rotation. Bits may bind if they

are misaligned or when they are breaking through

a hole. Wood boring bits can also bind if they run

into nails or knots. Be prepared for bit binding

situations.

To reduce the chance of bit binding:

• Use sharp bits. Sharp bits are less likely to bind

when drilling.

• Use the proper bit for the job. There are bits that

are designed for specifi c purposes.

• Use caution when drilling pitchy, knotty, wet or

warped material or when drilling in material that

may contain nails.

Typical Bracing Methods