6

7

forward

reverse

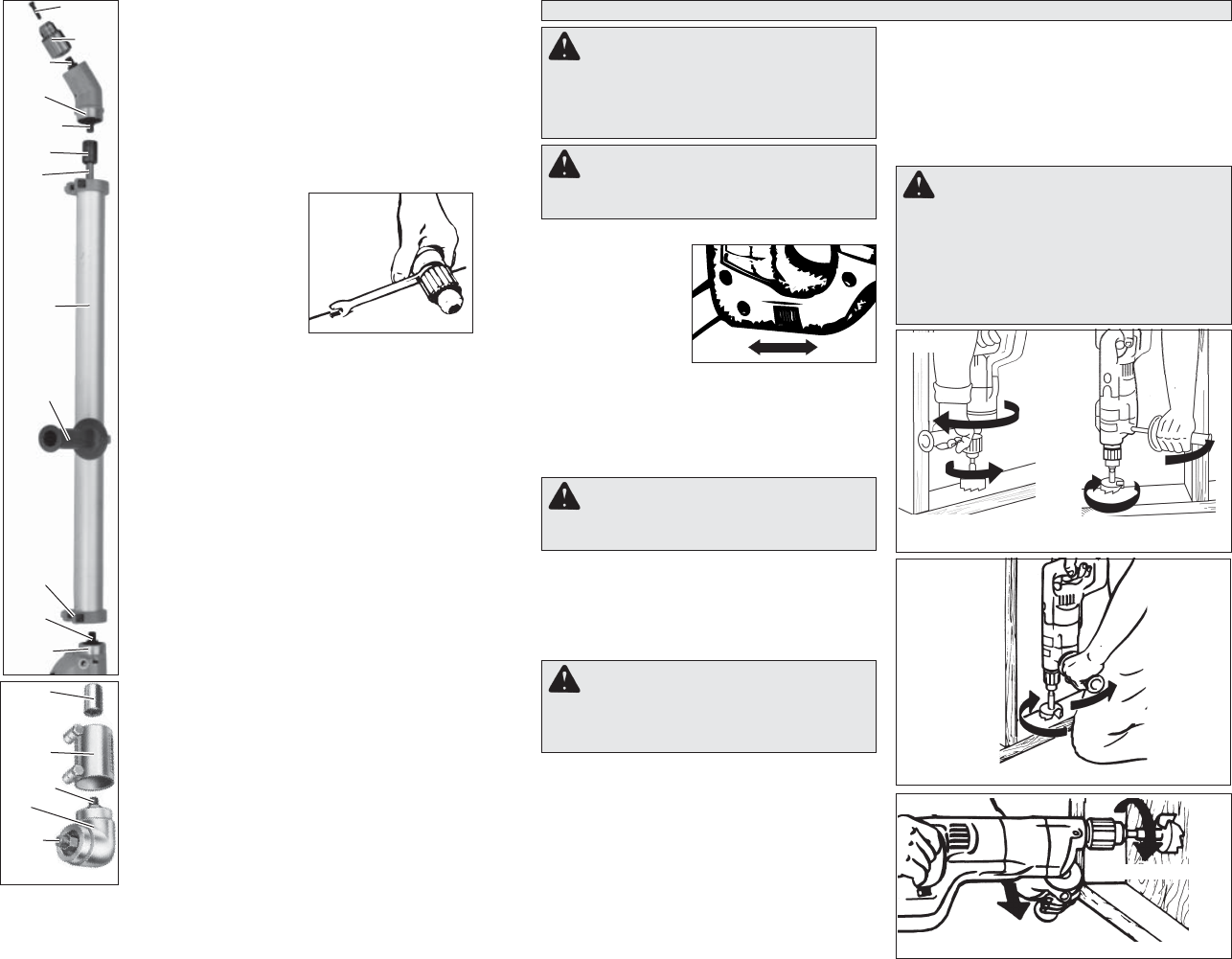

Installing 30"Extension Tube

The 30" extension tube MUST

be used when attaching the 33°

Angle Drive. The extension tube

can optionally be used with the

Right Angle Drive.

1. Remove the chuck from the

drill (see “Removing the Chuck

From the Drill”).

2. Slide extension tube over

drill collar and tighten clamp

securely.

3. Slide auxiliary side handle

onto 30" extension tube and

secure.

4. Insert drive shaft through 30"

extension tube.

5. Engage hex nut with hex drive

on drill.

Attaching 33° Angle Drive

1. Attach 33° angle drive by

inserting hex drive into hex

socket in extension drive shaft.

Secure with clamp.

2. Thread the chuck onto the 33°

angle drive spindle. INSTALL

CHUCK LOCKING SCREW.

Attaching Right Angle Drive

to Drill

1. Remove the chuck from the

drill (see “Removing the Chuck

From the Drill”). Slip the dou-

ble hex coupling over the hex

on the drill spindle.

Loosen the clamping screws

on the clamping sleeve and

slip the sleeve onto the drill

collar.

2. Slide the Right Angle Drive

head into the other side

of the sleeve and turn the

drive head slightly in either

direction so the hexagonal

hole in the coupling engages

the hexagonal portion of the

spindle.

NOTE: Attaching the drill

chuck to the side marked

“LOW” reduces the speed

by 1/3, or 33%. Attaching the

drill chuck to the opposite

side increases the speed by

50%.

3. When assembled, turn the Right Angle Drive

head to the desired position and tighten the

clamping screws to secure the unit. Thread

the chuck onto the Right Angle Drive spindle.

INSTALL CHUCK LOCKING SCREW.

Auxiliary

side

handle

30"

Extension

tube

Clamp

Collar

Hex

drive

Drive

shaft

Hex

socket

Hex drive

Clamp

Locking

screw

Chuck

Spindle

Double

hex

coupling

Clamping

sleeve

Drill

head

Spindle

hexagon

Right

Angle

Drive

Spindle

Using Forward/Reverse Switch

1. For forward (clock-

wise) rotation, push

the forward/reverse

switch to FWD as

shown.

Check the direction

of rotation before

use.

2. For reverse (counterclockwise) rotation, push

the forward/reverse switch to REV as shown.

Check the direction of rotation before use.

Although an interlock prevents reversing the

tool while the motor is running, allow the motor

to come to a full stop before reversing.

Starting, Stopping and Controlling Speed

1. To start the tool, pull trigger.

2. To stop the tool, release the trigger.

3. To vary the speed, increase or decrease pres-

sure to the trigger. The further the trigger is

pulled, the greater the speed.

Drilling

1. Before drilling, be sure the workpiece is clamped

securely. Use backing material to prevent dam-

age to the workpiece during breakthrough.

2. When starting a hole, place the drill bit on the

work surface and apply fi rm pressure. Begin

drilling at a slow speed, gradually increasing the

speed as you drill.

3. Always apply pressure in line with the bit. Use

enough pressure to keep the drill biting, but do

not push hard enough to stall the motor.

4. Reduce pressure and ease the bit through the

last part of the hole. While the tool is still running,

pull the bit out of the hole to prevent jamming.

OPERATION

WARNING To reduce the risk of injury,

wear safety goggles or glasses with side

shields.

WARNING To reduce the risk of injury,

always unplug tool before attaching or remov-

ing accessories or making adjustments. Use

only specifi cally recommended accessories.

Others may be hazardous.

WARNING To reduce the risk of injury,

keep hands and cord away from the bit and

all moving parts.

WARNING To reduce the risk of explo-

sion, electric shock and property damage,

always check the work area for hidden pipes

and wires before drilling.

Attaching Right Angle Drive to 30" Extension

1. Attach right angle drive by inserting spindle

hexagon into hex socket in extension drive shaft.

Secure with clamp.

2. Thread the chuck onto the right angle drive

spindle. INSTALL CHUCK LOCKING SCREW.

Removing Chuck From Angle Drive Units

The chuck can be removed from the angle drive

unit in the same manner it is removed from the

drill; however, ALWAYS REMOVE ANGLE DRIVE

FROM THE DRILL BEFORE ATTEMPTING TO

LOOSEN THE CHUCK.

This will prevent dam-

aging the drill's gear-

ing. Use the open end

wrench provided to hold

the angle drive spindle

before attempting to

loosen the chuck.

Bracing against the fl oor

reaction

forward rotation

Fig. 3

Bracing against your leg

forward

rotation

Fig. 2

reaction

reaction

forward rotation

reverse rotation

Bracing against a stud

reaction

Fig. 1

WARNING To reduce the risk of per-

sonal injury, hold the tool securely. Brace

tools with side handles as shown (Fig. 1, 2 &

3). If the bit binds, the tool will be forced in

the opposite direction. Bits may bind if they

are misaligned or when breaking through a

hole. Wood boring bits can also bind if they

run into nails or knots.

Stalling

If the tool seems as if it is about to stall, maintain a

fi rm grip and reduce pressure slightly to allow the

bit to regain speed. If the tool does stall, release

the trigger immediately. Reverse the motor, remove

the bit from the work and start again. Do not pull

the trigger on and off in an attempt to start a stalled

drill. This can damage the drill.