20

21

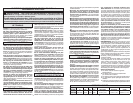

Fig. B

Fig. C

Fig. A

GROUNDING

Grounded Tools: Tools with Three Prong Plugs

Tools marked “Grounding Required” have a three

wire cord and three prong grounding plug. The

plug must be connected to a properly grounded

outlet (See Figure A). If the tool should electrically

malfunction or break down, grounding provides a

low resistance path to carry electricity away from

the user, reducing the risk of electric shock.

The grounding prong in the plug is connected

through the green wire inside the cord to the

grounding system in the tool. The green wire in the

WARNING Improperly connecting the

grounding wire can result in the risk of elec-

tric shock. Check with a qualifi ed electrician

if you are in doubt as to whether the outlet is

properly grounded. Do not modify the plug

provided with the tool. Never remove the

grounding prong from the plug. Do not use

the tool if the cord or plug is damaged. If

damaged, have it repaired by a MILWAUKEE

service facility before use. If the plug will not

fi t the outlet, have a proper outlet installed by

a qualifi ed electrician.

cord must be the only wire connected to the tool's

grounding system and must never be attached

to an electrically “live” terminal. Your tool must be

plugged into an appropriate outlet,

properly installed and grounded in

accordance with all codes and ordi-

nances. The plug and outlet should

look like those in Figure A.

Double Insulated Tools: Tools with Two Prong Plugs

Tools marked “Double Insulated” do not require

grounding. They have a special double insulation

system which satisfi es OSHA requirements and

complies with the applicable standards of Underwrit-

ers Laboratories, Inc., the Cana-

dian Standard Association and the

National Electrical Code. Double

Insulated tools may be used in ei-

ther of the 120 volt outlets shown in

Figures B and C.

In specifi c countries, double insulated tools could

be used in the out-

put connections suit-

able for the plug.

21

20

19

18

22

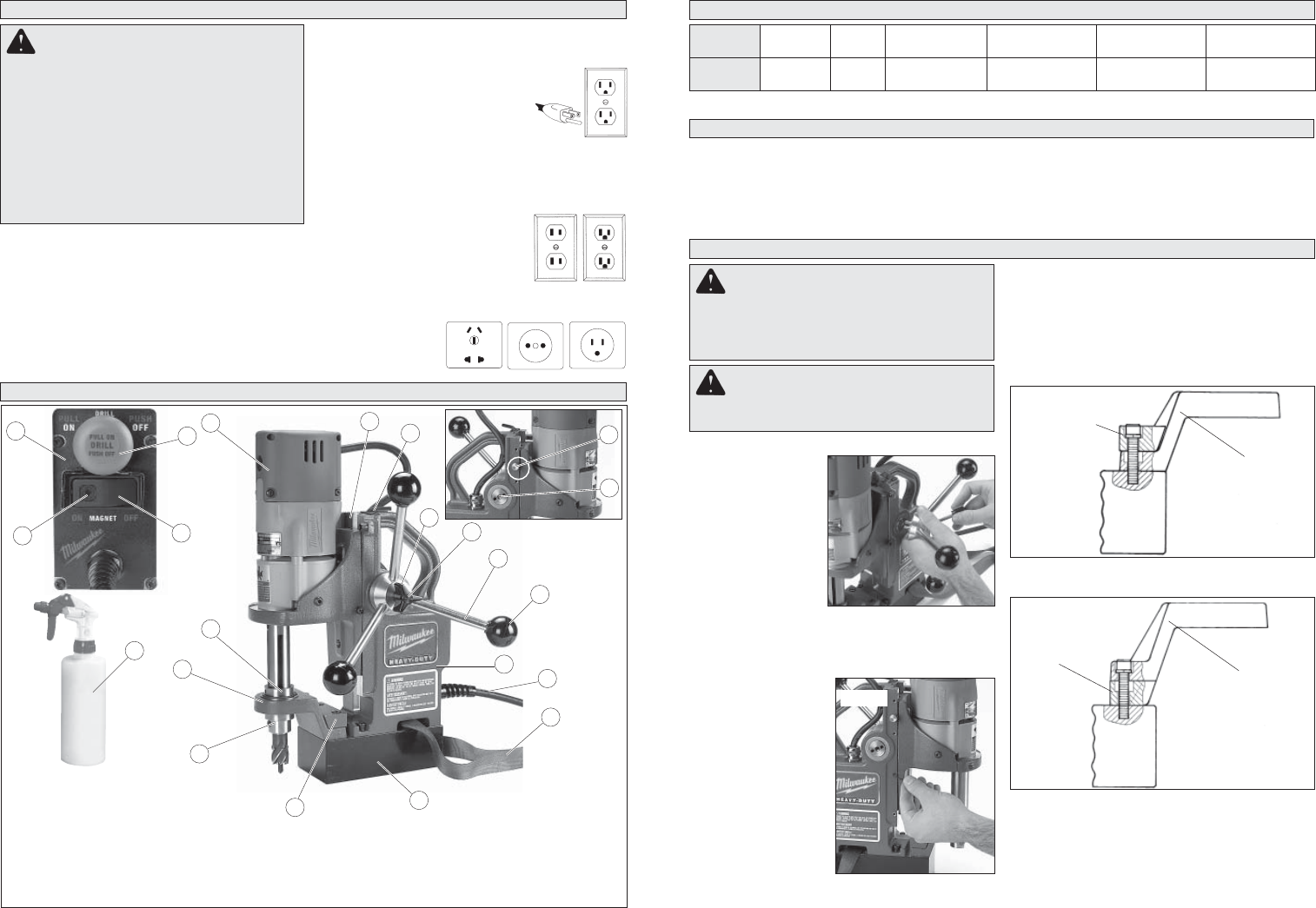

1. Drill motor

2. Slide

3. Wrench storage

(includes 3/32" and

3/16" hex keys)

4. Stop knob

5. Pinion

6. Hub

7. Handle screw

14

9

11

12

10

13

16

15

7

17

1

8. Feed handle

9. Grip

10. Housing

11. Cord

12. Safety strap

13. Magnetic base

14. Spacer

15. Drill spindle

16. Support bracket

17. Cutting fl uid reservoir

18. Control panel

19. Magnet indicator light

20. Magnet switch

21. Drill on/off switch

22. Hand pump

2

3

4

5

8

6

FUNCTIONAL DESCRIPTION

ASSEMBLY

WARNING To reduce the risk of injury,

always unplug tool before attaching or remov-

ing accessories or making adjustments. Use

only specifi cally recommended accessories.

Others may be hazardous.

WARNING To reduce the risk of injury,

wear safety goggles or glasses with side

shields.

Line Lockout

The line lockout prevents the drill motor from start-

ing when line power is fi rst applied to the system

or after a momentary power loss. To reset tool,

turn magnet switch to "OFF" position and drill on/

off switch to "OFF" position.

FEATURES

Cat. No. Volts AC W No Load RPM

Arbor

Bore

*Twist

Drill

HSS

Cutter

4270-59

4270-59A

220-240

220-240

1050

1050

450

450

19 mm (3/4")

19 mm (3/4")

13 mm (1/2")

13 mm (1/2")

38 mm (1-1/2")

38 mm (1-1/2")

* Requires use of 1/2" drill chuck adapter

SPECIFICATIONS

Attaching Feed Handles and Grips

1. Assemble the feed

handles and grips

to the hub. Tighten

securely.

2. To mount the hub

to either side, align

the two (2) dowel

pins on the hub

with the holes in

the pinion. Tighten

the handle screw.

Fig. 1

Fig. 4

Support bracket

Spacer

When using 2" depth cutters, install support bracket

with spacer on bottom, as shown in Fig. 4.

Stop Knob

The stop knob is designed to stop the slide from

moving. To install, screw stop knob into place.

Adjusting the Gib Assembly

To adjust the gib, loos-

en or tighten the gib

adjustment set screws

on the side of the sup-

port housing accord-

ingly with the 3/32" hex

key provided. Tight-

ening the set screws

increases friction on the

slide. The gib should

be set tight enough to

support the weight of

the drill in any position.

All adjusting screws

should be set to provide

smooth and even travel over the entire length of

slide movement.

Fig. 2

The set screws contain a nylon patch that prevents

them from moving freely. Additional adjustment

of the gib may be required from time to time with

extended use of the tool.

Adjusting the Support Bracket and Spacer for

Depth of Cut

This unit is shipped from the factory set for 1" depth

cutters (Fig. 3).

Fig. 3

Support bracket

Spacer

NOTE: Do not use a spacer and support bracket

with chuck adapter.

Motor/Magnet Interlock

The motor/magnet interlock is a feature that pre-

vents power from being applied to the drill motor

if the magnet is not energized. The motor magnet

interlock also prevents the magnet from being de-

energized while the motor is running.