4 5

8. Never use dull or damaged bits. Sharp

bits must be handled with care. Dam-

aged bits can break during use. Dull bits

require more force to push the tool, which

could cause the bit to break. Damaged

bits can throw carbide pieces and burn

the workpiece.

9. After changing the bit or making any

adjustments, make sure the collet

nut and any other adjustment de-

vices are securely tightened. Loose

adjustment devices can unexpectedly

shift, causing loss of control. Loose

rotating components will be violently

thrown. Watch for vibration or wob-

bling that could indicate an improperly

installed bit.

10. Maintain fi rm grip on router when start-

ing motor to resist starting torque.

11. Always keep the power supply cord

away from moving parts on the tool.

Keep the cord away from the direction of

the cut.

12. Never start the tool when the bit is in

contact with the material. The bit cut-

ting edge may grab the material causing

loss of control of the tool.

13. Never lay the tool down until the bit

has come to a complete stop. The

spinning bit can grab the surface and pull

the tool out of your control.

14. Never touch the bit during or immedi-

ately after use. After use the bit may be

hot enough to burn bare skin.

15. Use clamps or another practical way

to secure and support the workpiece

to a stable platform. Holding the work

by hand or against your body leaves it un-

stable and may lead to loss of control.

16. Never clamp the workpiece to a hard

surface, such as concrete or stone.

Contact with the bit could cause the tool

to jump and loss of control.

17. Only operate the routers when held.

Do not clamp or secure the router to

a surface and hold the workpiece by

hand.

18. Never use bits larger than the smallest

of the openings in the base, sub-base,

or dust collection port.

19. Do not loosen or

remove the plunge

base caps. Internal

springs are under

pressure. If loos-

ened or removed, the

plunge base caps and

internal springs will

become projectiles,

which could cause

injury.

Amperes

Double Insulated

Symbology

Canadian Standards

Association

Underwriters

Laboratories, Inc.

Volts Alternating Current

No Load Revolutions

per Minute (RPM)

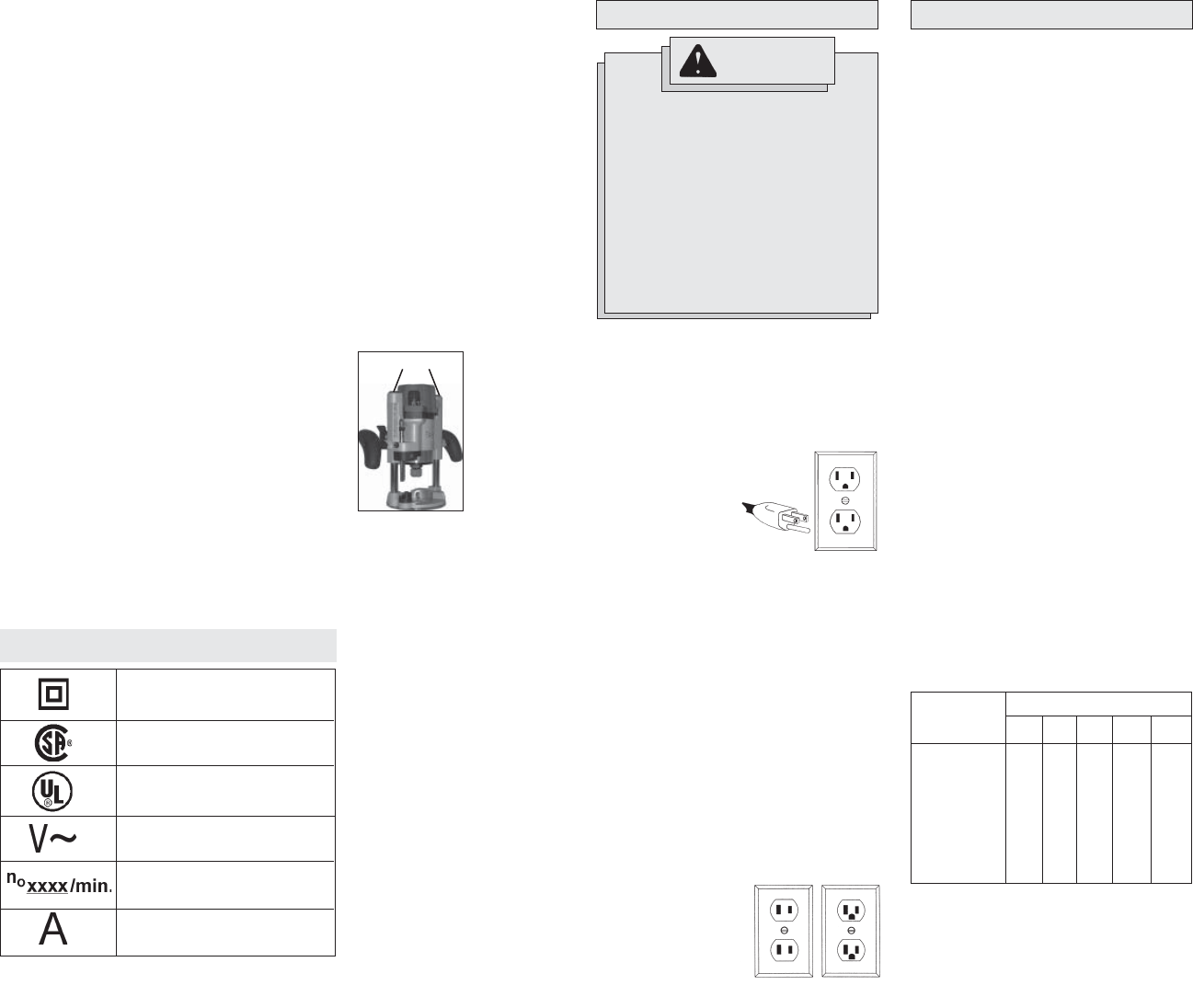

The grounding prong in the plug is connected

through the green wire inside the cord to the

grounding system in the tool. The green wire

in the cord must be the only wire connected

to the tool's grounding system and must never

be attached to an electrically “live” terminal.

Your tool must be plugged into an appropri-

ate outlet, properly installed and grounded in

accordance with all codes and ordinances.

The plug and outlet should look like those

in Figure A.

Double Insulated Tools:

Tools with Two Prong Plugs

Tools marked “Double Insulated” do not

require grounding. They have a special

double insulation system which satisfies

OSHA requirements and complies with the

applicable standards of Underwriters Labo-

Grounded Tools:

Tools with Three Prong Plugs

Tools marked “Grounding Required” have a

three wire cord and three prong grounding

plug. The plug must be connected to a prop-

erly grounded outlet (See Figure A). If the tool

should electrically malfunction or break down,

Fig. B Fig. C

Fig. A

Improperly connecting the grounding

wire can result in the risk of electric

shock. Check with a qualifi ed electri-

cian if you are in doubt as to whether

the outlet is properly grounded. Do not

modify the plug provided with the tool.

Never remove the grounding prong

from the plug. Do not use the tool if the

cord or plug is damaged. If damaged,

have it repaired by a MILWAUKEE ser-

vice facility before use. If the plug will

not fi t the outlet, have a proper outlet

installed by a qualifi ed electrician.

GROUNDING

WARNING

grounding provides a

low resistance path to

carry electricity away

from the user, reduc-

ing the risk of electric

shock.

ratories, Inc., the Cana-

dian Standard Associa-

tion and the National

Electrical Code. Double

Insulated tools may be

used in either of the 120

volt outlets shown in

Figures B and C.

Grounded tools require a three wire extension

cord. Double insulated tools can use either

a two or three wire extension cord. As the

distance from the supply outlet increases,

you must use a heavier gauge extension cord.

Using extension cords with inadequately sized

wire causes a serious drop in voltage, result-

ing in loss of power and possible tool damage.

Refer to the table shown to determine the

required minimum wire size.

The smaller the gauge number of the wire,

the greater the capacity of the cord. For

example, a 14 gauge cord can carry a higher

current than a 16 gauge cord. When using

more than one extension cord to make up

the total length, be sure each cord contains

at least the minimum wire size required. If

you are using one extension cord for more

than one tool, add the nameplate amperes

and use the sum to determine the required

minimum wire size.

Guidelines for Using Extension Cords

• If you are using an extension cord out-

doors, be sure it is marked with the suffi x

“W-A” (“W” in Canada) to indicate that it

is acceptable for outdoor use.

• Be sure your extension cord is prop-

erly wired and in good electrical

condition. Always replace a damaged

extension cord or have it repaired by a

qualifi ed person before using it.

• Protect your extension cords from sharp

objects, excessive heat and damp or wet

areas.

READ AND SAVE ALL

INSTRUCTIONS FOR

FUTURE USE.

Recommended Minimum Wire Gauge

for Extension Cords*

Extension Cord Length

* Based on limiting the line voltage drop to

fi ve volts at 150% of the rated amperes.

Nameplate

Amperes

0 - 2.0

2.1 - 3.4

3.5 - 5.0

5.1 - 7.0

7.1 - 12.0

12.1 - 16.0

16.1 - 20.0

25'

18

18

18

18

16

14

12

75'

18

18

16

14

12

10

100'

18

16

14

12

10

150'

16

14

12

12

50'

18

18

18

16

14

12

10

EXTENSION CORDS

Plunge Base Caps