10 11

WARNING

To reduce the risk of injury, wear

safety goggles or glasses with side

shields.

Unplug the tool before changing ac-

cessories or making adjustments.

Never make adjustments while the

router is running.

DO NOT use the router if the lock-

ing lever does not hold the motor

securely in the base.

NEVER use the Plunge Base Router

models in a router table.

OPERATION

For deeper cuts:

1. Align the "0" on the scale with the arrow

on the tool.

2. Rotate depth adjustment knob clockwise

to desired depth measurement.

For shallower cuts:

1. Align the desired depth measurement

with the arrow on the tool.

2. Rotate depth adjustment knob counter-

clockwise to "0."

Push in locking lever to fully closed position

when fi nished adjusting.

When using a socket wrench, place the

router upside down on a fl at surface and fully

open the locking lever. Insert a 3/8" socket

wrench into the hole on the base and turn to

desired depth (Fig. 12). Push in locking lever

to fully closed position.

Installing the Bit

It is not necessary to remove the motor from

the base to install a collet assembly or a bit. If

removal of the base is desired, see previous

section. Always remove wood chips, dust or

other foreign materials from the collet shaft

and collet assembly before assembling.

Insert the collet assembly into the collet shaft.

Insert the bit shank into the collet as follows:

1. Unplug the tool.

2. Insert the bit shank into the collet as far

as it will go.

3. Back the bit shank out slightly to avoid

bottoming out.

4. Be sure there is a minimum of 1/16" be-

tween the bottom of the collet assembly

and the radius to the cutting portion of

the bit (Fig. 10).

WARNING

To reduce the risk of injury, wear

safety goggles or glasses with side

shields.

Always unplug the tool before at-

taching or removing accessories or

making adjustments.

Use only specifi cally recommended

accessories. Others may be hazard-

ous.

Never use bits larger than the smallest

of the openings in the base, sub-base,

or dust collection port.

5. Be sure that the collet is not clamped

to a fl uted section on the bit shank. The

collet should be clamped to a solid part

on the bit shank to ensure a tight grip.

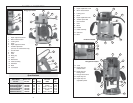

To tighten the bit in the collet assembly, use

two wrenches (Fig. 11).

Removing the Bit

1. Unplug the tool.

2. Loosen the collet nut from the collet shaft

using two wrenches.

3. Once loose, unscrew the collet nut by

hand until it feels tight again.

4. Use the wrenches again until the bit

shank can be pulled out.

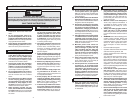

Fig. 10

Minimum

1/16"

Bit shank

Collet

Collet nut

Fig. 11

Fig. 12

Templet Guides

A 1-3/16" center hole sub-base is needed to

use a template guide.

To install a templet guide, insert the guide

into the center hole of a 1-3/16" router base

and secure according to the templet guide

instructions.

Fig. 9

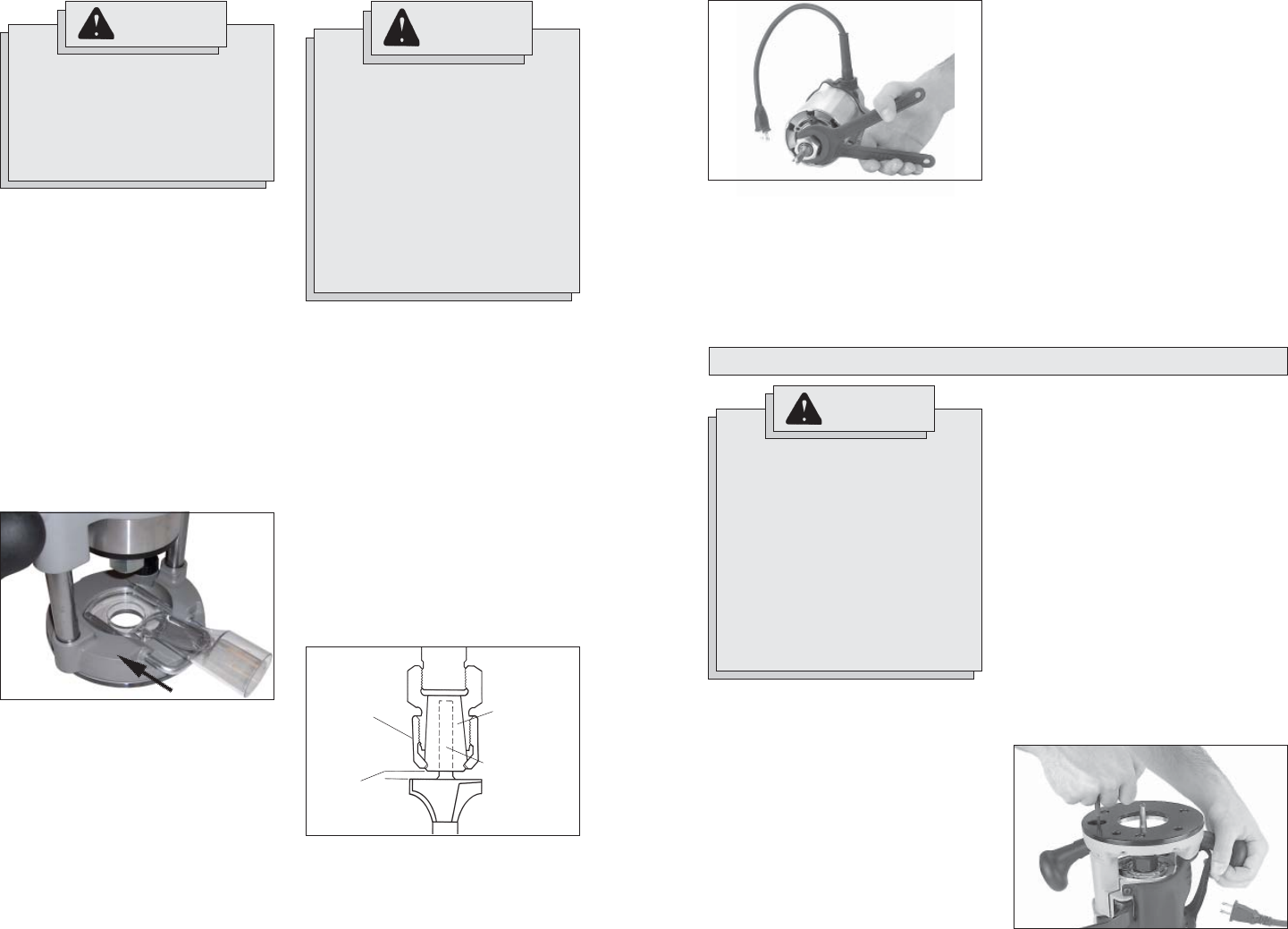

WARNING

To reduce the risk of injury, do not use

the dust collection port when plunge

cutting if the bit is larger than the port

opening (1-3/8"). If a rotating router

bit contacts the dust collection port,

the port will break and fl ying debris

may cause injury.

Installing the Dust Collection Port (not

available on the Production model)

1. If an edge guide has been installed, it

must be removed temporarily to install

the dust collection port.

2. Loosen the rod screws.

3. Place the router upright and set the circle

into the base (as shown in Fig. 9).

4. Slide the rods through the base rod

holes and into the port rod holes.

NOTE: Use either the rods supplied with

the dust collection port or rods from a

MILWAUKEE edge guide.

5. Tighten the rod screws.

6. Twist a vacuum hose into the end of the

port.

Adjusting the Depth of Cut

Bodygrip®, D-Handle and Production

models:

The tool depth can be adjusted by using

the depth adjustment knob or a 3/8" socket

wrench with an extension, or the Above-the-

table Depth Wrench (Cat. No. 49-96-0370).

When using the depth adjustment knob, fully

open the locking lever and rotate knob to

the desired depth of cut. One revolution of

the depth adjustment knob is equal to 0.2".

For fi ne adjustments less than 5/32", use

the independent scale on the depth adjust-

ment knob.

NOTE: Never tighten a collet assembly

without inserting a bit shank of the proper

size. This may damage the collet.