8

MANTA I

Revision 03/05, Effective Date March 2, 2005

9

MANTA I

Revision 03/05, Effective Date March 2, 2005

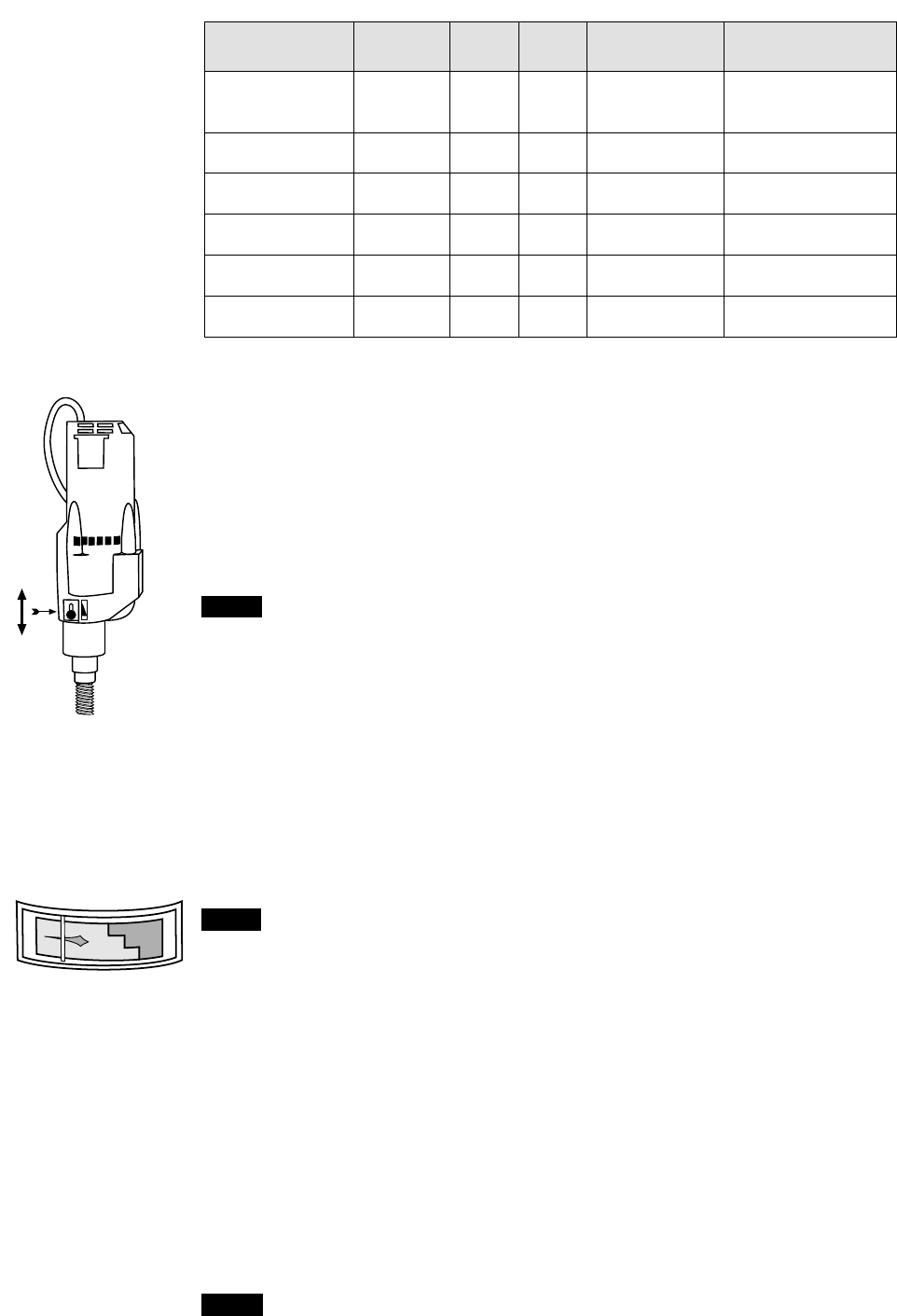

The MK-Manta I will operate in either a high or low gear speed. This speed combined

with applied pressure provides the cutting action for the core bit. Speed selection and

pressure are determined by hardness of material, aggregate size and grade of diamond

core bit. Generally, harder material and larger aggregates require more speed and

pressure. Use low speed for large diameter bits and high speed for small diameter bits.

Changing of the speeds is accomplished by using the speed shift lever built into the

gear case.

Notice: Change the gears only when the motor is off.

All building materials and work surfaces are composed of aggregate of various size.

Aggregates are materials such as gravel or crushed stone. The size of the grains and

the hardness of the material affects the speed of drilling. Most building materials contain

some type of steel reinforcements. All MK bits are designed to cut through these types

of reinforcing steel. However, bits should never be used for drilling solid steel plates.

Proper selection of the diamond core bit should be based on material to be drilled and

performance requirements.

Steady, even pressure assures accurate holes and longer bit life. Always maintain

consistent pressure so that the bit is constantly cutting.

Notice: Too much pressure will damage the bit and motor. Too little pressure will

glaze over the diamonds, reducing cutting efficiency and prematurely wearing the bit.

The ammeter is the gauge on the Control Box. It provides pressure feedback information

during drilling, allowing the operator to help prevent motor overload and premature bit

wear. The green area is the operating range, and the red area is the overload range.

Generally, the operator should keep the ammeter needle in the upper area of the

operating range for large diameter bits, and in the lower green area for small diameter

bits. If the bit contacts steel reinforcing rods, the needle on the ammeter may jump

slightly showing a heavier load. If this occurs, do not decrease pressure or you may

damage the diamonds. The Manta may be operated with the ammeter needle into the

red area for the short period of time that it takes to cut through a steel rod.

An adequate supply of clean water is necessary for drilling. Connect the water supply

hose to the hose fitting on the output of core drill motor. Take precautions that the water

supply will not be interrupted during the drilling operations.

Notice: If a bit is run dry it can be ruined in a few seconds.

Water Supply

Drilling Speeds

Drilling Pressure

and the Ammeter

LOW

HIGH

A

M

P

S

20

15

18

Manufacturer Model # AMP Volts Speed(RPM) Suggested Dia. in

Medium Aggregate

Eibenstock EBM

300/3 P

20 120 Low – 270

Medium – 700

High – 1250

Low – 4”

Medium – 2”-6”

High – 3/4”-4”

Milwaukee 4004 20 120 Low – 300

High – 600

Low – 4”

High – 14”

Milwaukee 4090 15 120 Low – 375

High – 750

Low – 5”-8”

High – 2 1/2”-5”

Milwaukee 4094 20 120 Low – 450

High – 900

Low – 6”-10”

High – 2”-6”

Milwaukee 4096 20 120 Low – 450

High – 900

Low – 6”-10”

High – 2”-6”

Milwaukee 4097-20 15 120 Low – 500

High – 1000

Low – 1 1/4”

High – 5”