40

List of fault displays

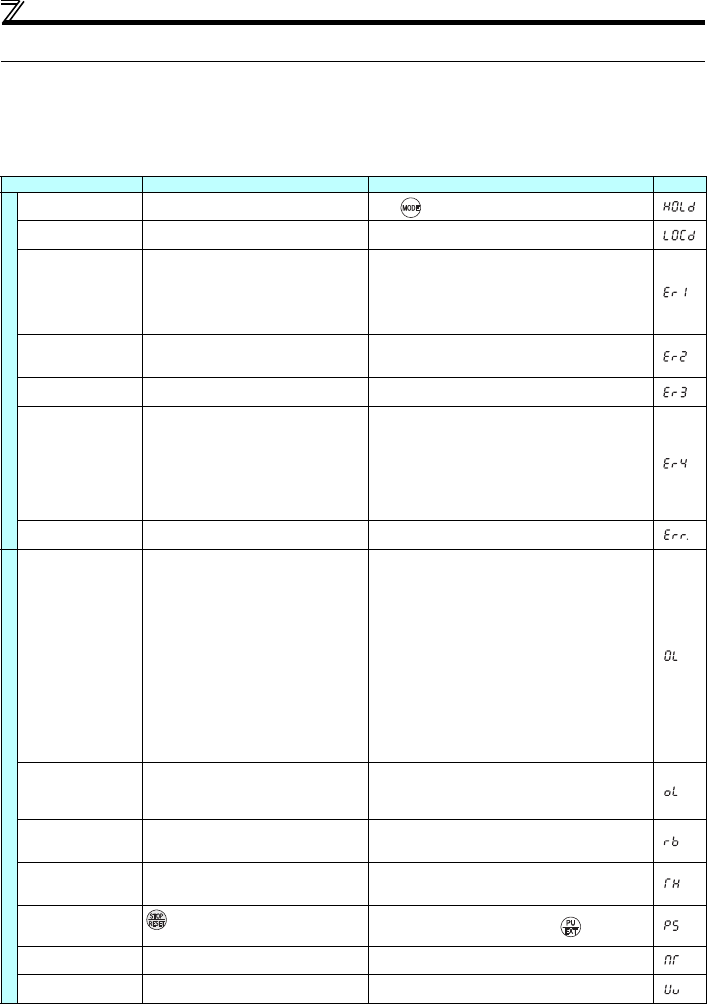

8.2 List of fault displays

When a fault occurs in the inverter, the inverter trips and the PU display automatically changes to one of the following fault or

alarm indications.

The error message shows an operational error. The inverter output is not shut off.

Warnings are messages given before faults occur. The inverter output is not shut off.

Alarms warn the operator of failures with output signals. The inverter output is not shut off.

When faults occur, the protective functions are activated to inverter trip and output the fault signals.

Function Name Description Corrective action Display

Error message

Operation panel lock

Operation has been attempted during the

operation panel lock.

Press for 2s to release the lock.

Password locked

Reading/writing of a password-restricted

parameter has been attempted.

Enter the password in Pr. 297 Password lock/unlock to unlock the

password function before operating.

Write disable error

Parameter setting has been attempted although

parameter writing is set to be disabled.

Overlapping range has been set for the

frequency jump.

PU and the inverter cannot make normal

communication.

Check the setting of Pr. 77 Parameter write selection.

Check the settings of Pr. 31 to Pr. 36 (frequency jump).

Check the connection of PU and the inverter.

Write error during

operation

Parameter writing has been attempted while a

value other than "2" is set in Pr. 77 Parameter write

selection and the STF (STR) is ON.

Set "2" in Pr. 77 Parameter write selection.

After stopping the operation, set parameters.

Calibration error

Analog input bias and gain calibration values have

been set too close.

Check the settings of calibration parameters C3, C4, C6 and C7

(calibration functions).

Mode designation error

Parameter setting has been attempted in the

External or NET operation mode when Pr.77

Parameter write selection is not "2."

Parameter writing has been attempted when the

command source is not at the operation panel.

After setting the operation mode to the "PU operation mode,"

set parameters.

Set "2" in Pr.77 Parameter write selection.

Disconnect the USB cable from the USB connector and the

parameter unit (FR-PU04/FR-PU07) from the PU connector,

then set Pr. 551 PU mode operation command source selection =

"9999 (initial setting)."

Set Pr. 551 PU mode operation command source selection = "4."

Inverter reset

The reset signal (RES signal) is ON.

(Inverter output is shutoff.)

Turn OFF the reset command.

Warning

Stall prevention

(overcurrent)

The overcurrent stall prevention has been

activated.

Increase or decrease the Pr. 0 Torque boost setting by 1% and

check the motor status.

Set the acceleration/deceleration time longer.

Reduce the load. Try Advanced magnetic flux vector control or

General-purpose magnetic flux vector control.

Check the peripheral devices for faults.

Adjust the Pr. 13 Starting frequency setting. Change the Pr. 14

Load pattern selection setting.

Set the stall prevention operation current in Pr. 22 Stall

prevention operation level. (The acceleration/deceleration time

may change.) Increase the stall prevention operation level

with Pr. 22 Stall prevention operation level, or disable stall

prevention with Pr. 156 Stall prevention operation selection.

(Operation at OL occurrence can be selected using Pr. 156

Stall prevention operation selection.)

Stall prevention

(overvoltage)

The overvoltage stall prevention function has been

activated.

(This warning is also output during the

regeneration avoidance operation.)

Set the deceleration time longer.

Regenerative brake

prealarm

The regenerative brake duty has reached 85% of

the Pr. 70 Special regenerative brake duty setting or

higher.

Set the deceleration time longer.

Check the Pr.30 Regenerative function selection and Pr. 70 Special

regenerative brake duty settings.

Electronic thermal relay

function prealarm

The cumulative value of the electronic thermal O/L

relay has reached 85% of the Pr. 9 Electronic

thermal O/L relay setting or higher.

Reduce the load and frequency of operation.

Set an appropriate value in Pr. 9 Electronic thermal O/L relay.

PU stop

on the operation panel has been pressed

during the External operation.

Turn the start signal OFF and release with .

Maintenance signal

output

The cumulative energization time has exceeded

the maintenance output timer set value.

Setting "0" in Pr. 503 Maintenance timer erases the signal.

Undervoltage

The voltage at the main circuit power has been

lowered.

Investigate the devices on the power supply line such as the

power supply itself.