ASSEMBLY INSTRUCTIONS/OPERATIONS

8FP FLOOR PLANER SERIES OPERATION AND PARTS MANUAL REV #2 (05/28/09) PAGE 18

Suggested Applications:

1) Removing synthetic coatings, thermoplastic and

cold plastic marking and lines from concrete and

asphaltic surfaces.

COST 10

PRODUCTIVITY 7

SERVICE LIFE 7. Milling flails are designed to remove

a variety of traffic line materials from concrete and

asphaltic type surfaces. With proper techniques,

minimal amounts of parent work surface material will

also be removed during the planing process. Milling

flails are expensive. To realize maximum service life,

milling flails should not be utilized for the direct

removal of concrete and asphaltic work surface

materials. Such use will drastically reduce their

service life and subst

antially increase project costs.

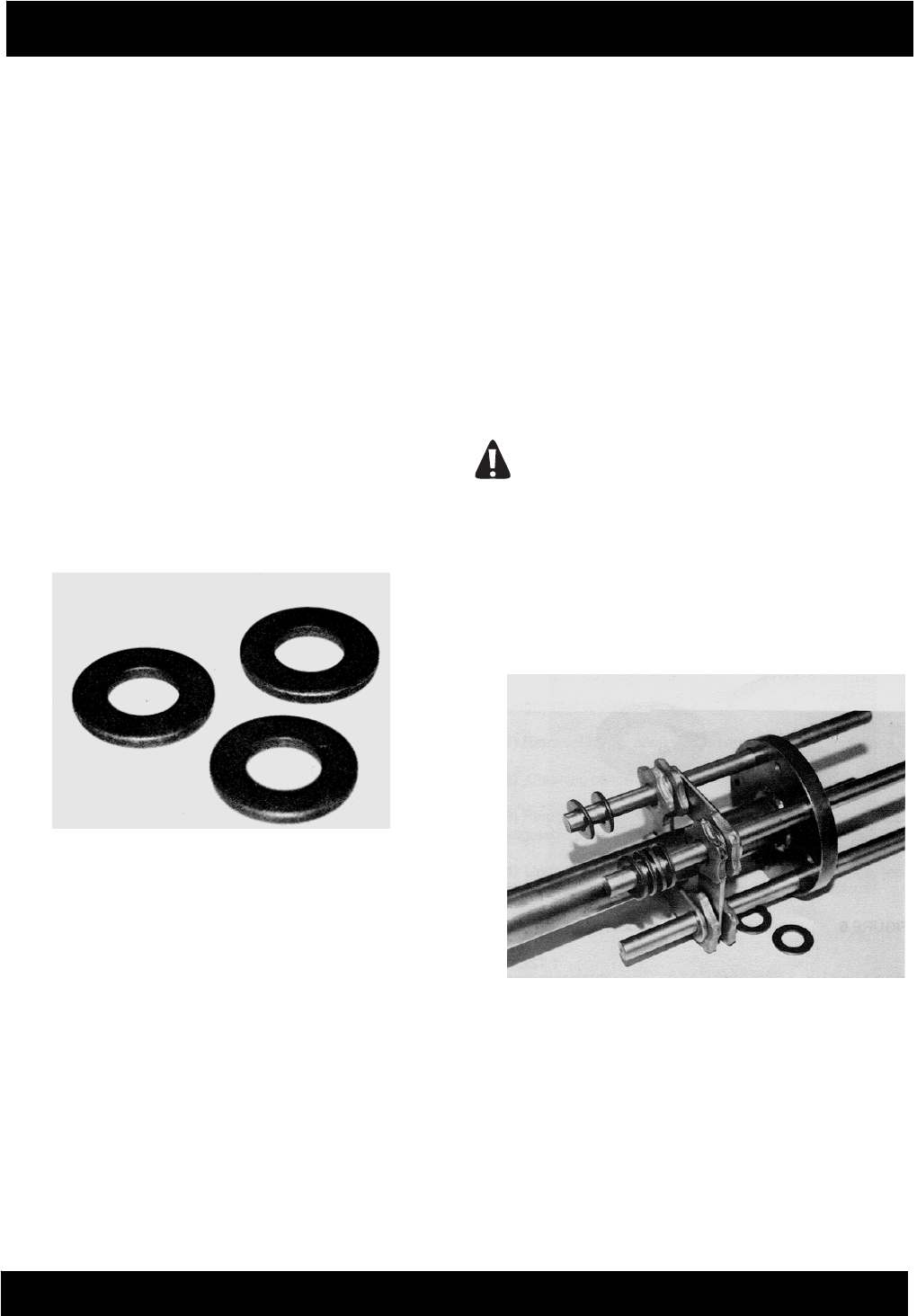

SPACER WASHERS.

Spacer washers are stamped from high carbon, a lloy

steel that is heat treated for additional service life.

FIGURE 6.

FIGURE 6

The Function of Spacer Washers

1) Reduce the number of flails required to be mounted

on the flail drum, thus reducing purchase and

operational costs.

2) Arrange the flails in a sequence or pattern that

minimizes "blind" or "open" spots created by the

additional support plates of the two section flail drum.

Always insert at least one spacer washer between two

(2) consecutive flails. The exception to this rule is a

configuration where its design does not require the

use of spacer washers. A flail drum set up with only

star, bea

m or pentagonal flails and no spacer washers

will not penetrate the work surface a t satisfactory

rates. Typical configurations minimize the hammering

or impact action of the flails. However, this can also be

useful when removing traffic lines.

3) Allow the flails to be arranged on the one section

flail drum in configurations of specific widths for many

job applications. An example would be the use of

pentagonal flails to groove a concrete floor. The

spacer washers are used to position the pentagonal

flails at the desired width. FIGURE 7.

Variances in ma

terial thickness and manufacturing

processes can affect the final thickness of both flails

and spacer washers. Because of this occurrence, trial

and error is important for assembling flails and spacer

washers on a flail drum. By mixing and matching flails

and spacer washers of specific thicknesses, the

required number of components can be assembled on

a flail drum in a minimum amount of time.

DANGER

USE ONLY FACTORY SUPPLIED SPACER

WASHERS ON THE FLAIL DRUM. OTHER

WASHER TYPES AND/OR CONFIGURATIONS CAN

PRODUCE ABNORMAL WEAR AND ELONGATION,

RESULTING IN COMPLETE SEPARATION FROM

THE FLAIL DRUM. SPACER WASHER

SEPARATION CAN RESULT IN PROPERTY LOSS

AND/OR PERSONAL INJURY.

FIGURE 7

FLAIL DRUM RODS

Flail drum rods are manufactured from 1/2 inch

diameter alloy steel. They are heat treated in a two

step process that yields a surface hardness that

resists wear and extends service life.

Drum rod service life is difficult to predict because of

the large number of flail configurations and work

surface materials. Normal wear should be uniform

about the rod circumference. FIGURE 8.