ASSEMBLY INSTRUCTIONS/OPERATIONS

8FP FLOOR PLANER SERIES OPERATION AND PARTS MANUAL REV #2 (05/28/09) PAGE 35

FIGURE 38.

11) If the Floor Planer is powered by an engine,

reconnect the engine spark plug wire. If powered by

an electric motor and the machine is to be used

immediately, reconnect the extension cord or Floor

Planer to the power source. Determine that the

ON/OFF switch located on the operator handle is in

the OFF position.

DANGER

UNEXPECTED MACHINE START UP CAN RESULT

IN PROPERTY DAMAGE AND/OR PERSONAL

INJURY.

INSTALLING A REPLACEMENT BEARING ON THE

V-BELT SIDE.

Application: All Models.

Tools Required:

1 each, 9/16 inch wrench.

1 each, 7/16 inch wrench.

1 each, torque wrench, 35 ft lbs (47 Nm.) capacity with

9/16 inch socket.

1 each, 5/16 inch Allen wrench.

1 each, pliers for large, external type snap rings.

1 each, shop press.

Parts Required:

1 each, PN 29020-016 sealed ball bearing.

1 each, container of bearing and shaft locking grade,

anaerobic adhesive/sealant.

1 each, PN 290020-011 snap ring (if required).

1 each, PN 29020-015 driveshaft (if required)

1) If the Floor Planer is powered by an engine,

disconnect the spark plug wire. If powered by an

electric motor, disconnect the extension cord or Floor

Planer from the power source.

2) Position the Floor Planer on a suitable work surface

with the V-belt approxima

tely at waist level.

3) Using the 9/16 inch wrench, remove the belt guard

from the main frame. Clean the inside of the belt guard

with an appropriate solvent. Check for signs of wear

and damage.

CAUTION

Observe all applicable safety precautions for the

solvent.

4) Remove the V-belt and driveshaft pulley. Refer to

INSTALLING A REPLACEMENT V-BELT OR PULLEY

for specific information.

5) Using the 5/16 inch Allen wrench and 9/16 inch

wrench, remove the bearing block/driveshaft assembly

from the main frame. For accuracy and alignment

purposes, the main frame incorporates tapped holes to

properly position the capscrews.

6) Position the driveshaft assembly on a suitable work

surface. Use the snap ring pliers to remove the snap

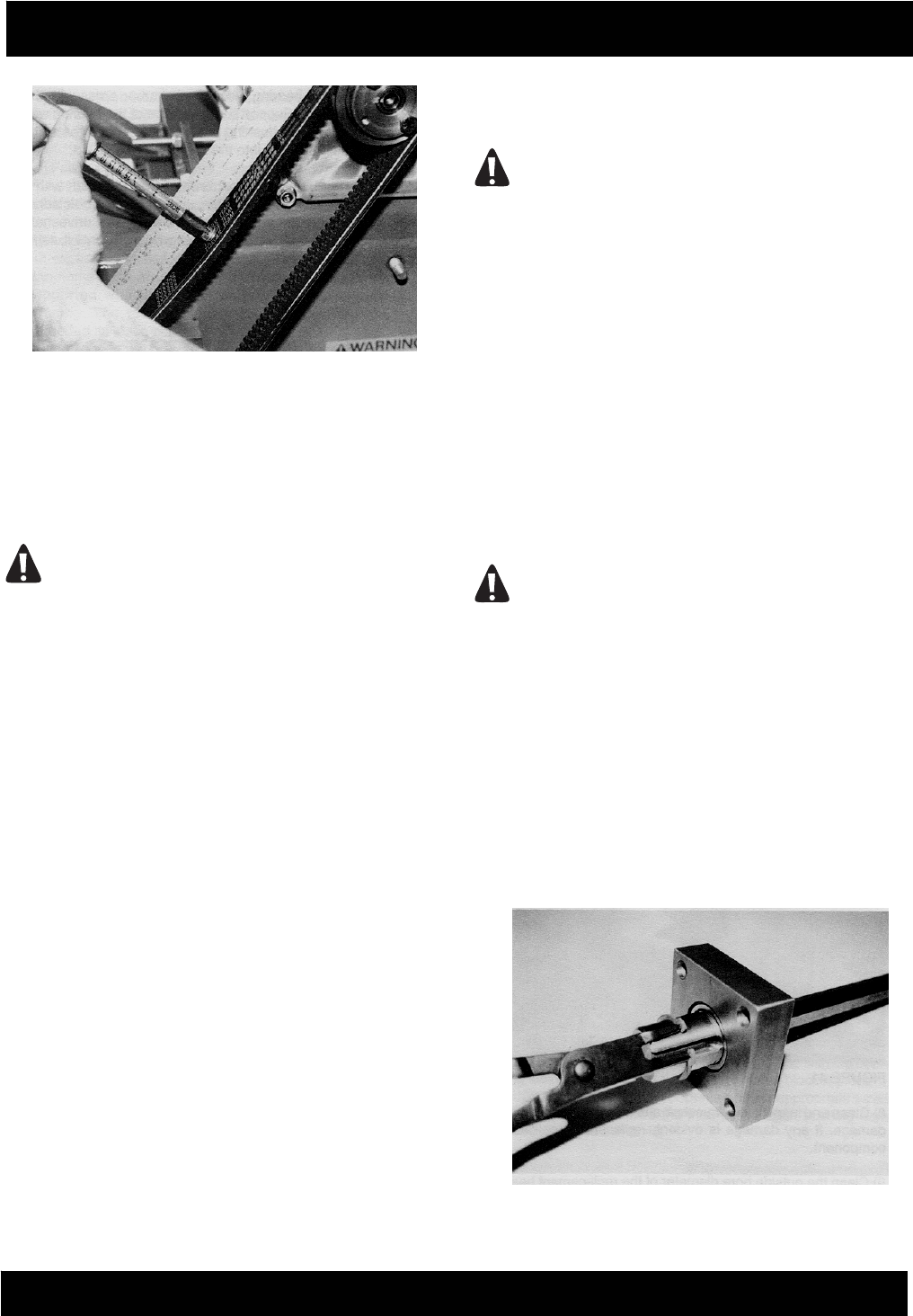

ring. FIGURE 39. Remove the spacer.

CAUTION

Wear safety glasses and other appropriate safety

apparel when removing the snap ring or

performing any work with an arbor press. Caution

all onlookers about the possibility of flying debris

and personal injury.

7) Position the driveshaft assembly in a suitable arbor

press. Determine that the outer race of the bearing is

properly supported. Press the bearing/driveshaft

assembly from the bearing block. FIGURE 40.

Reposition the assembly and press the bearing from

the bearing block. FIGURE 41.

FIGURE 39