MQ-WHITEMAN FS2/FS2SP CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (06/26/06) — PAGE 31

General Transmission Care

All FS2SP Models utilize spline gear wheel design coupled

with an EATON Model 7 Hydrostatic Transmission that provides

forward/reverse propulsion. The simple design of the system

keeps maintenance to a minimum.

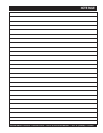

1. Transmission Reservoir Cup: Check every 8 hours

of operation. When the transmission is

cold

(A), check oil

level against the level indicator (see Figure 26).

DO NOT use multiple viscosity oils! DO NOT OVERFILL.

2. Servicing: The transmission reservoir is factory filled.

Should servicing be required, use SAE20W-20, API classi-

fication (SE,CC,CD) or better, General Motors Dexron B,

Ford M2C-33F, M2C-41A or International Harvester Hy-Tran

fluids. For extreme

hot weather

, drain oil and refill with an

oil having a viscosity of SAE30W-30 or SAE40W-40.

3. Drive Chain: Check every 50 hours. Periodically wipe the

chain clean and relubricate with penetrating chain oil.

The drive chain may stretch requiring tension adjustments.

Loosen the (3) transmission attachment screws (see page

68, item 11), and pivot the transmission in the

“U” slots

of

the

transmission mount

until the proper tension is achieved.

(see page 68, item 33). EXCESSIVE TENSION ON THE

DRIVE CHAIN WILL REDUCE CHAIN LIFE.

4. SPLINE GEAR WHEELS: Check every 25 hours and clean

as necessary. If the spline wheels DO NOT engage the

rear

wheels

with sufficient pressure, slippage of the rear wheels

may occur.

To adjust the

Spline Gear Assembly

, place the transmis-

sion disengage lever in the

DISENGAGE

position. Remove

the

rear console cover

(see page 52, item 19). Loosen the

linkage adjustment nut and slightly lengthen the linkage rod

(see page 68, items 12 and 13). Recycle the transmission

ENGAGE/DISENGAGE

lever to observe the proper spline-

to-rear wheel contact. Retighten adjustment nut and return

Rear Console Cover.

FS2/FS2SP CONCRETE SAW — MAINTENANCE

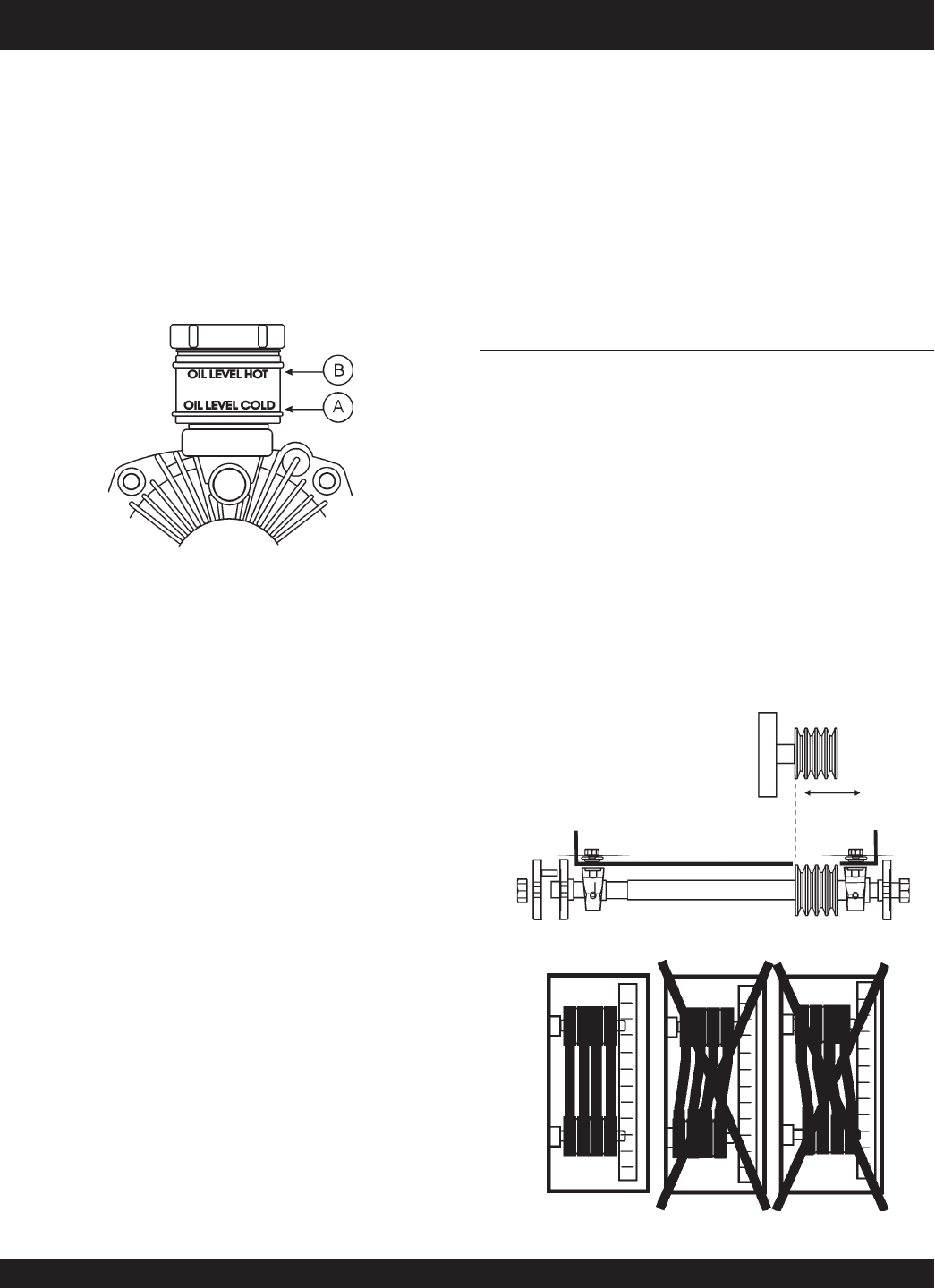

Adjust V-Belt Alignment/Replacement Pulleys

The V-belts and their respective pulleys have been professionally

aligned at the factory. If there is a requirement to remove/replace

or adjust the pulleys, proceed with the following instructions.

1. Select the proper sized pulley both in outside diameter and

arbor size. Use approved Multiquip parts to ensure the

component compatibility.

2. A change in Pulley diameters may require specifically sized

V-Belts. Contact Multiquip Service Department to en-

sure V-Belt compatibility.

Complete Drive V-Belt(s) Replacement steps (1 through 7)

3. Remove the V-Belts from around the Pulley(s).

4. Remove the set screws that secure the pulleys to the respec-

tive shafts (PTO shaft) for engine pulley or the (blade shaft)

for the blade shaft pulley.

5. Remove/replace the pulley by sliding it off the shaft.

6. Reorient the new pulley on the shaft, and ensure precise

pulley alignment by utilizing an accurate straight edge (see

Figures 27 and 28).

7. Replace/tighten set screws treated with a drop of

LOCTITE

Threadlocker 266.

8. Orient the proper replacement V-Belt(s) around the blade

shaft pulley and engine pulley.

9. Reference the final stages of the Drive V-Belt(s) Replace-

ment steps.

Figure 28. V-Belt Alignment

Figure 27. Pulley Alignment

Figure 26. Transmission Reservoir