MQ-WHITEMAN FS3SP CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #0 (07/15/02) — PAGE 33

FS3SP CONCRETE SAW — MAINTENANCE

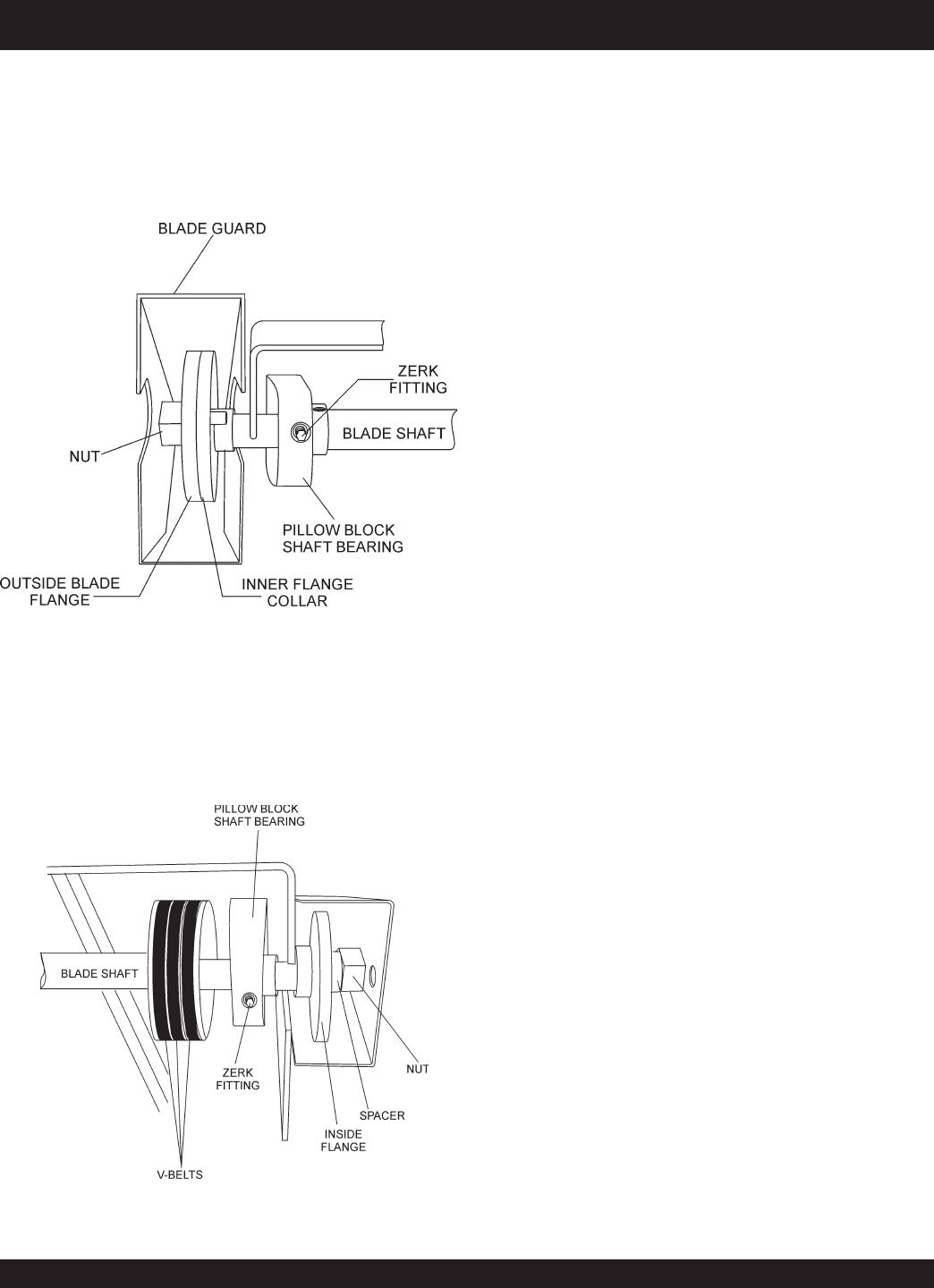

Blade Shaft Bearing Replacement

The FS3SP is supported by “tapped base lock collar (w/set

screw)’ self-aligning blade shaft bearings. These heavy duty

bearings support the 1-1/4 blade shaft, and have grease (zerk)

points (Figures 28 and 29) conveniently located for service.

Figure 28. Right-Side Shaft Bearing

1. Reference pages 46 (

Blade Shaft Assembly

) and

72 (

Engine Mount Assembly

).

2. Its recommended to replace both left & right hand bearings

collectively.

Figure 29. Left-Side Shaft Bearing

3.

To loosen the tension on the three V-Belts perform the

following:

z

Remove the

Belt Guard

, item, page 50, item 17

(Pointers and Covers Assembly)

z

Loosen the

Carriage Bolt

, page 48, item 4 (Engine

Mount Assembly).

z

Loosen the

Hex Head Cap Screws

, page 48, item 7

(Engine Mount Assembly).

z

Rotate the engine down to provide slack in the V-Belts

Replacement of the Blade Shaft Bearings

4. Perform the following to replace the blade shaft bearings:

z

Remove

blade flanges

(page 46, items 7 and 8,

Blade

Shaft Assembly

) as required to permit the Shaft Bearing(s)

to slide off the blade shaft.

z

Loosen/remove

shaft bearing(s)

hex head cap screws

,

page 44, item 11.

z

Loosen

set screw

on the blade shaft bearing collar.

z

Slide “old” bearing(s) off the blade shaft and replace with

“new” bearing(s)- grease (zerk) fitting pointing forward, and

the lock collar oriented to the “right" as you face the saw.

5. Loosely bolt the bearing(s) into place on the saw frame, then

ensure the alignment by referencing past bearing position-

ing.

6. Tighten the hex head cap screw, page 46, item 11 to secure

the shaft bearing (s) to the frame.

7. To complete the re-installation process, reverse the order of

the above mentioned steps. For V-belt adjustmemt and

tensioning see pages 32 (Figures 26 and 27) and page

34(Figure 30).

W — TRANSMISSION ASSY.