MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 29

Engine Oil Replacement:

1. Replace engine oil in the first 25 hours of operation and

every 50 to 100 hours afterwards.

2. Oil may be drained more easily when it is warm after

operation (For more details, see separate engine Owner's

Manual).

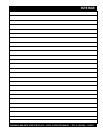

Air Filter

1. The air filter element should be cleaned because a clogged

air cleaner can cause poor engine starting, lack of power

and shorten engine life substantially.

2. To clean or replace air filter loosen the wing nut on the air

filter housing (Figure 24) remove the cover and take out air

filter cartridge. If only cleaning of the air filter is desired blow

through the air filter cartridge from the inside, moving a jet of

dry compressed air up and down until all dust is removed.

Figure 24. Engine Air Filter and Element

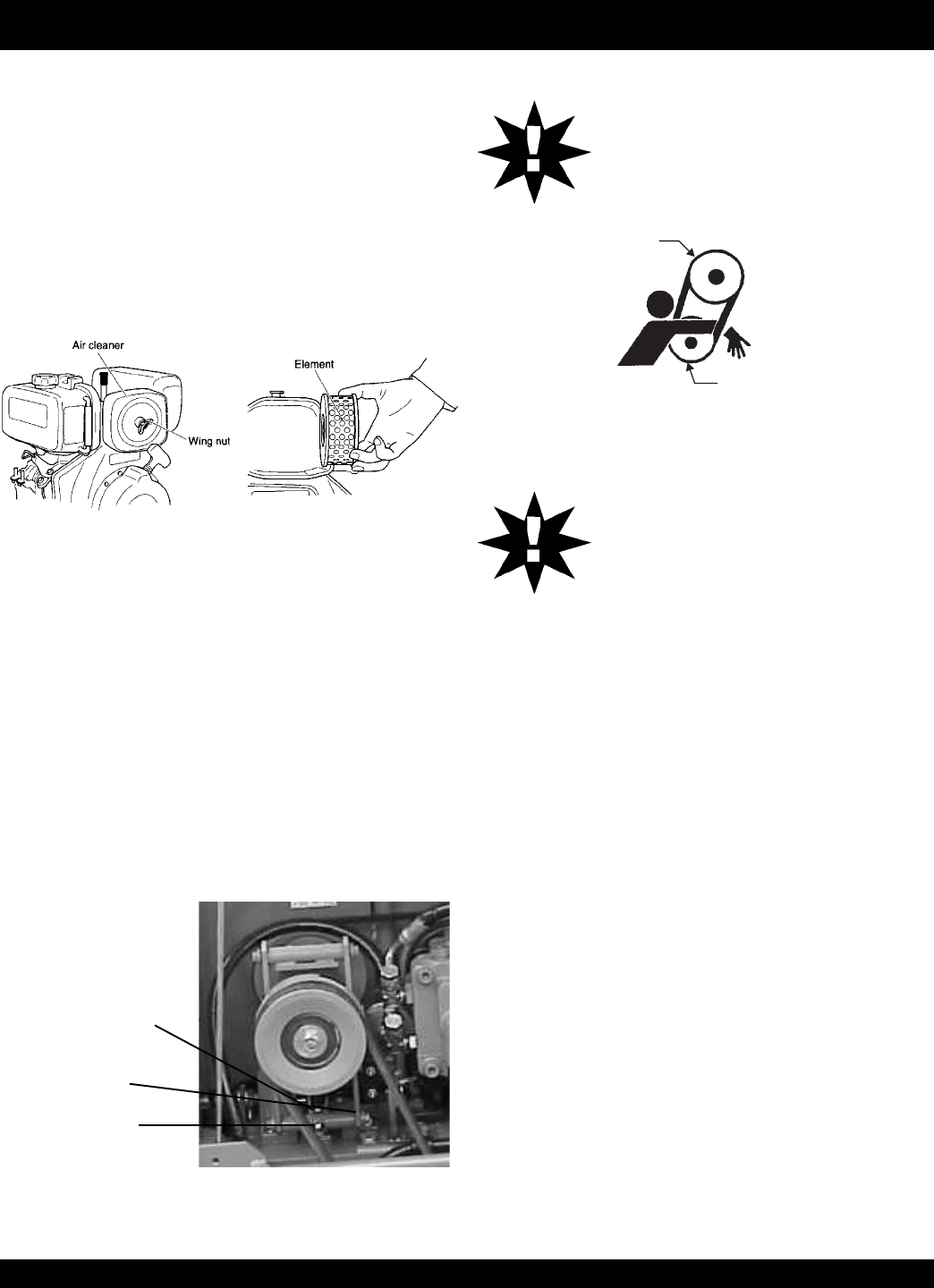

VIBRATION CLUTCH ADJUSTMENT

1. Move vibration lever to the OFF position.

2. Loosen the front and rear nuts at the end of vibration clutch

cable (Figure 25).

3. Turn in the nut on the front side again and at the position

that release fork starts to move, turn in the nut by one or two

threads. Lock it a this position together with the rear nut.

Figure 25. Vibration Clutch Adjustment

Rear Nut

Front Nut

Fork

CLUTCH

PULLEY

VIBRATOR

PULLEY

Figure 26. V-Belt Hazard

HYDRAULIC SYSTEM INSPECTION AND SERVICE

1. Check motor and pump for any damage.

2. Check hoses and pipes for proper tightness and make sure

there are no leaks.

3. Check nylon tubes for hydraulic oil intake and drain.

Retighten brass nut if loose and if a leak is detected. If leak

continues after retightening, replace nylon tube, nut and

sleeve.

4. Check oil tank for proper oil level using the hydraulic system

oil level gauge (See Figure 7). Make sure hydraulic oil has

not whitened or emulsified. Whitish color means aeration in

pump. Retighten pipe and correct level of oil. Emulsification

means water in the hydraulic oil. Replace the oil.

CAUTION:

NEVER attempt to check the V-belt with the en-

gine running. Severe injury can occur if your hand

gets caught between the V-belt and the clutch

(Figure 26). Always use safety gloves.

Excessive turning of front nut may cause the

sliding engagement of clutch to take place or

no vibration takes place even when vibration

lever is engaged.

On the other hand, insufficient turn may cause

sliding engagement of clutch even when the

vibration lever is placed in the OFF position or

for vibration to remain engaged.

CAUTION :

ROLLER INSPECTION AND ADJUSTMENT

1. Refer to Table 8 for oil and grease requirements.

2. Check oil tank level daily.

3. Check the machine for oil leak and proper function of lever,

cables, and links daily.

MRH-800DS—MAINTENANCE