Ver: 10/14/2004 9

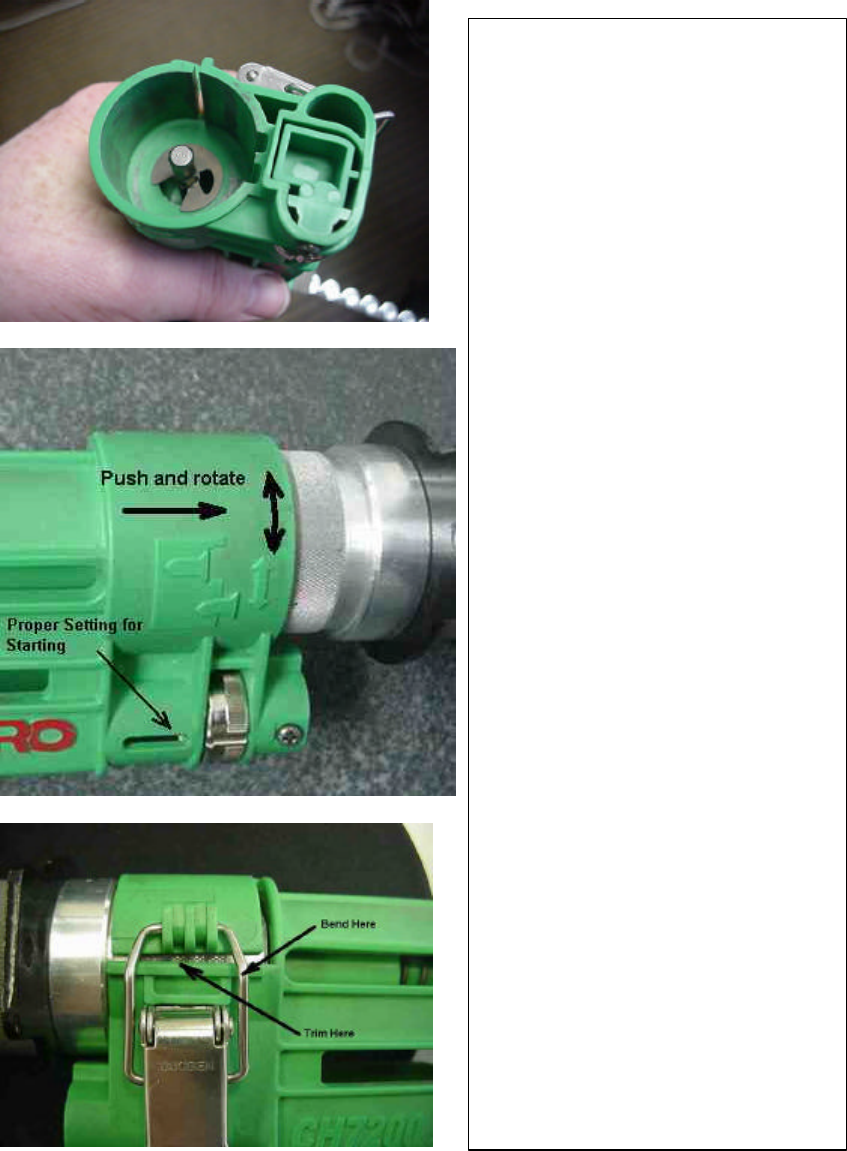

When the bit and clip are

assembled into the CH7260, it may

then be attached to the driver tool.

Rotate the attachment to allow the

small hex end of the bit to mate

with the driver. Once mated, push

the attachment fully onto the

aluminum adaptor. Latch the hasp.

. (Tip: if more latching force is

required after a period of use, the

wire part of the hasp can be bent

with pliers to re-

tension the clasp. If

very badly worn, the plastic sides

may touch and some plastic must

be removed from the metal clip side

with a blade to provide clearance

for clamping.)

For Wood applications set the

screw gun torque to Max and set

the starting depth control on the

attachment to the middle of the

adjust range and adjust attachment

depth adjustment to suit.

Hex screws are normally seated

using the torque control of the

screw gun to prevent “stripping

out” or fastener breakage. Set

starting torque per chart and adjust

torque until it seats consistently.

The depth control on the attachment

is set to “deep” to allow this per

middle photo.