6

Northern Industrial Welder

O

p

eratin

g

Instructions and Parts Manual

Flux Core 125

Wire Feed, Gasless Welder

High pressure cylinders can explode

if damaged, so treat them carefully.

-Never expose cylinders to high heat,

sparks, open flames, mechanical

shocks or arcs

-Do not touch cylinder with MIG gun.

-Do not weld on the cylinder.

-Always secure cylinder upright to a

cart or stationary object cart or

stationary object

-Do not touch cylinder with MIG gun.

-Do not weld on the cylinder.

-Always secure cylinder upright to a

cart or stationary object.

-Keep cylinders away from welding or

electrical circuits.

-Use the proper regulators, gas hose

and fittings for the specific application

Assembly

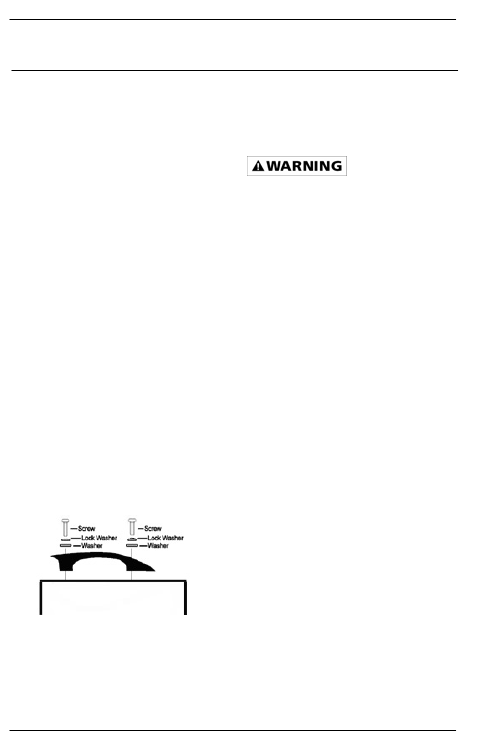

INSTALLING THE HANDLE

1. Line up the holes in the handles

with the holes on the top of the

welder.

2 Place a lock washer then a washer

onto the welder handle screws.

3 Insert the screws with the washers

through the holes on the welder

handle and into the top of the welder

and tighten.

MIG gun/torch assembled,

some assembly required for

ground cable.

Installation

1. Power requirement

AC single phase 115v (110-120V),

60HZ fused with a 20amp time

delayed fuse or circuit breaker is

required. DO NOT OPERATE THIS

UNIT if the ACTUAL power source

voltage is less than 105 volts ac or

greater than 132 volts ac.

• High voltage danger from power

source! Consult a qualified

electrician for proper installation of

receptacle. This welder must be

grounded while in use to protect

the operator from electrical shock.

• Do not remove grounding prong

or alter the plug in any way. Do

not use any adapters between the

welder’s power cord and the power

source receptacle. Make sure the

POWER switch is OFF when

connecting your welder’s power

cord to a properly grounded 115

VAC, 60Hz, 1 phase, 20 amp input

power supply.

2. Extension cord

We do not recommend an extension

cord because of the voltage drop they

produce. This drop in voltage can

affect the performance of the welder.

If you need to use an extension cord

it must be a size #12 gauge or larger.

Do not use an extension cord over 25

ft. in length.

3. Install the wire roller

Open the wire feed compartment.

Before installing any welding wire into

the unit, the proper sized groove must

be placed into position on the wire

drive mechanism. Adjust the drive

roller according to the following steps,

see following picture about the wire

feeder structure: