21

III. MAINTENANCE

The Blockbuster Compact requires very little maintenance for long satisfactory operation.

However, the following points must be watched:

A. V-Belts

The drive belts are made of premium oil and heat resistant materials. They require very little

adjustment, but should be tightened after the first few days of running.

Adjustment And Alignment

Warning: Never make adjustments to v-belts and pulleys while engine is running.

1. The best tension for a v-belt drive is the lowest tension at which the belts will not slip

under full load. The normal tension is 3.8 to 5.4 lbf. approx. 1/2” defection

2. Simply take up the drive until the belts are snug in the grooves. Run the drive for

about 15 minutes to "seat" the belts. Then impose the peak load. If the belts slip,

tighten them until they no longer slip at peak load.

3. Remember, too much tension shortens belt and bearing life.

4. Check belt tension frequently during the first day of operation. Check belt tension

periodically thereafter and make any necessary adjustments.

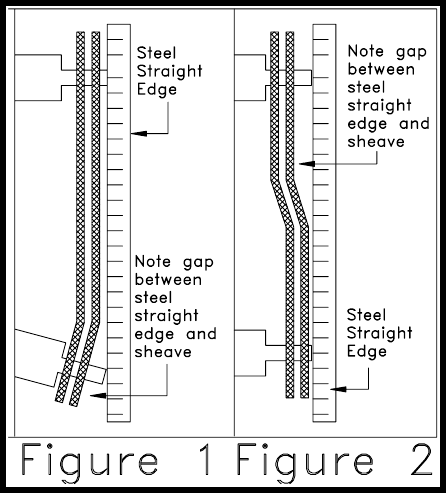

5. The two most common causes of misalignment are shown in the drawing.

a). The engine drive shaft pulley and the blade shaft are not parallel.[See figure 1]

b). The pulleys are not located properly on the shafts.[See figure 2]

6). To check alignment, all you need is a steel straight edge.

7). Line up the straight edge along the outside face of both pulleys as shown in the

drawing.

8). Misalignment will show up as a gap between the pulley face and the straight edge.

9). Make sure that the width of the outside land is equal on both pulleys.