2

I_

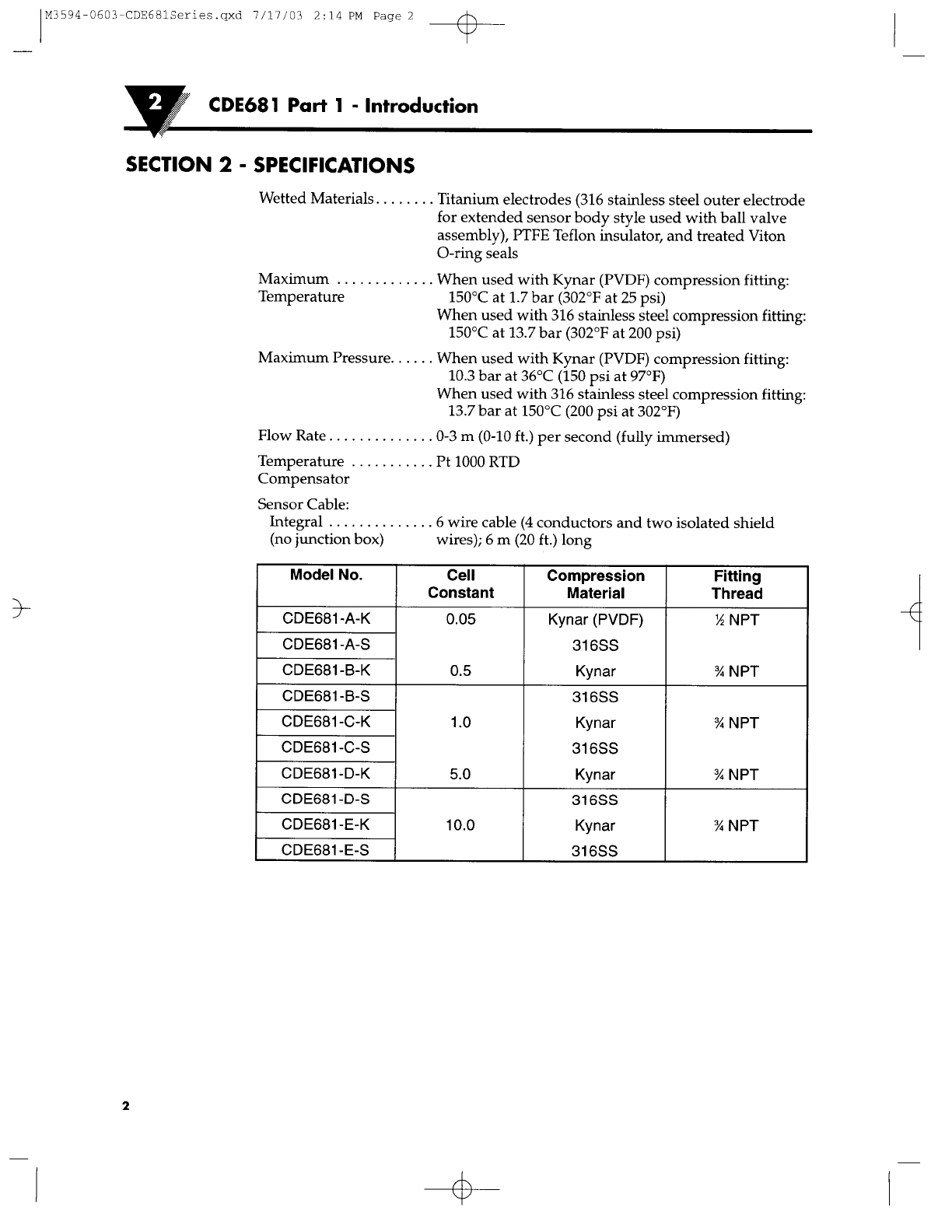

%

NPT

%

NPT

%

NPT

-

%

NPT

%

NPT

(

Compression

Material

K yna r ( PVDF )

316SS

K yna r

316SS

K yna r

316SS

K yna r

316SS

K yna r

316SS

Fitting

Thread

CDE681 - E - S

1

1

CDE681 - E - K10 . 0

I

CDE681 -D-S

.

Model No.

CDE681 - A - K

CDE681 - A - S

CDE681 - B - K

CDE681 - B - S

CDE681 - C - K

CDE681 - C - S

Cell

Constant

0 . 05

0 . 5

1 .0

CDE681 - D - K5 . 0

.

.

.

.

.

.

.

.

.

.

.

(no junction box) wires); 6 m (20 ft.) long

Flow Rate.

.

.

.

.

.

.

.

.

.

.

.

.6

wire cable (4 conductors and two isolated shieldIntegral

.

Compensator

Sensor Cable:

.

.

.

.

.

.

.

.

P t

1000 RTD

Temperature

.

.

O-3 m (O-10 ft.) per second (fully immersed)

.

When used with Kynar (PVDF) compression fitting:

10.3 bar at 36°C (150 psi at 97°F)

When used with 316 stainless steel compression fitting:

13.7 bar at 150°C (200 psi at 302°F)

.

When used with Kynar (PVDF) compression fitting:

150°C at 1.7 bar (302°F at 25 psi)

When used with 316 stainless steel compression fitting:

150°C at 13.7 bar (302°F at 200 psi)

.

. Titanium electrodes (316 stainless steel outer electrode

for extended sensor body style used with ball valve

assembly), PTFE Teflon insulator, and treated Viton

O-ring seals

.

.

.

Temperature

Maximum Pressure.

.

.

.

.

.

.

.

.

.

.

.

Maximum

.

.

.

.

-

SPECIFICATIONS

Wetted Materials.

-

Introduction

SECTION 2

-

CDE681 Part

1

m

2:14

PM Page 2

7/17/03

M3594-0603mCDE681Series.qxd