The linearity and accuracy of the FP-6000 Series

sensor depend on predictable flow conditions in

the pipe and proper location of the fitting. As

with any insertion flow sensor, the pipe must be full

and generally free of air pockets.

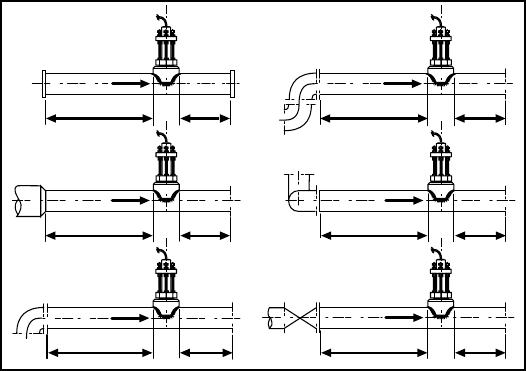

2.1 Location of Fitting

The sensor must be located in a free-flowing

straight run of pipe. OMEGA recommends a

minimum of 10 pipe diameters of straight pipe

upstream and a minimum of 5 diameters down-

stream to insure a fully developed flow profile.

Any obstructions to the flow will require consider-

ably longer straight runs. Figure 1 illustrates

several common situations and recommended

piping distances.

2

Chapter 2

Installation and

Wiring

2.2 Sensor Position

When installing the sensor in a horizontal pipe run

the optimum position is at 0° or 180°, assuming

the line is always full and contains no solids.

Air pockets or sediment in the line will disturb the

rotation of the paddlewheel, causing inaccuracy in

the calibration. Installing the sensor at an angle

Figure 1

Sensor upstream/

downstream mounting

requirements

15 X I.D. 5 X I.D.

Reducer

Flange

40 X I.D. 5 X I.D.

2 x 90° Elbow

3 dimensions

20 X I.D. 5 X I.D.

90° Elbow

50 X I.D. 5 X I.D.

Valve/Gate

10 X I.D. 5 X I.D.

25 X D 5 X I.D.

2 x 90°

Elbow

Inlet OutletInlet Outlet