613GC OPERATOR’S MANUAL

19

MAINTENANCE

CHAIN TENSIONER

The chain tensioner (Figure 1) can become clogged with concrete

slurry during cutting. After each use thoroughly flush the chain

tensioner with water. Then apply a liberal amount of grease.

Most Common Causes of Tensioner Damage:

• Side cover nuts are not tight enough. Side cover nuts

should be torqued to 20 ft-lbs (27Nm).

• Chain tensioning is attempted without loosening the

side cover nuts.

• Concrete debris in tensioner pocket.

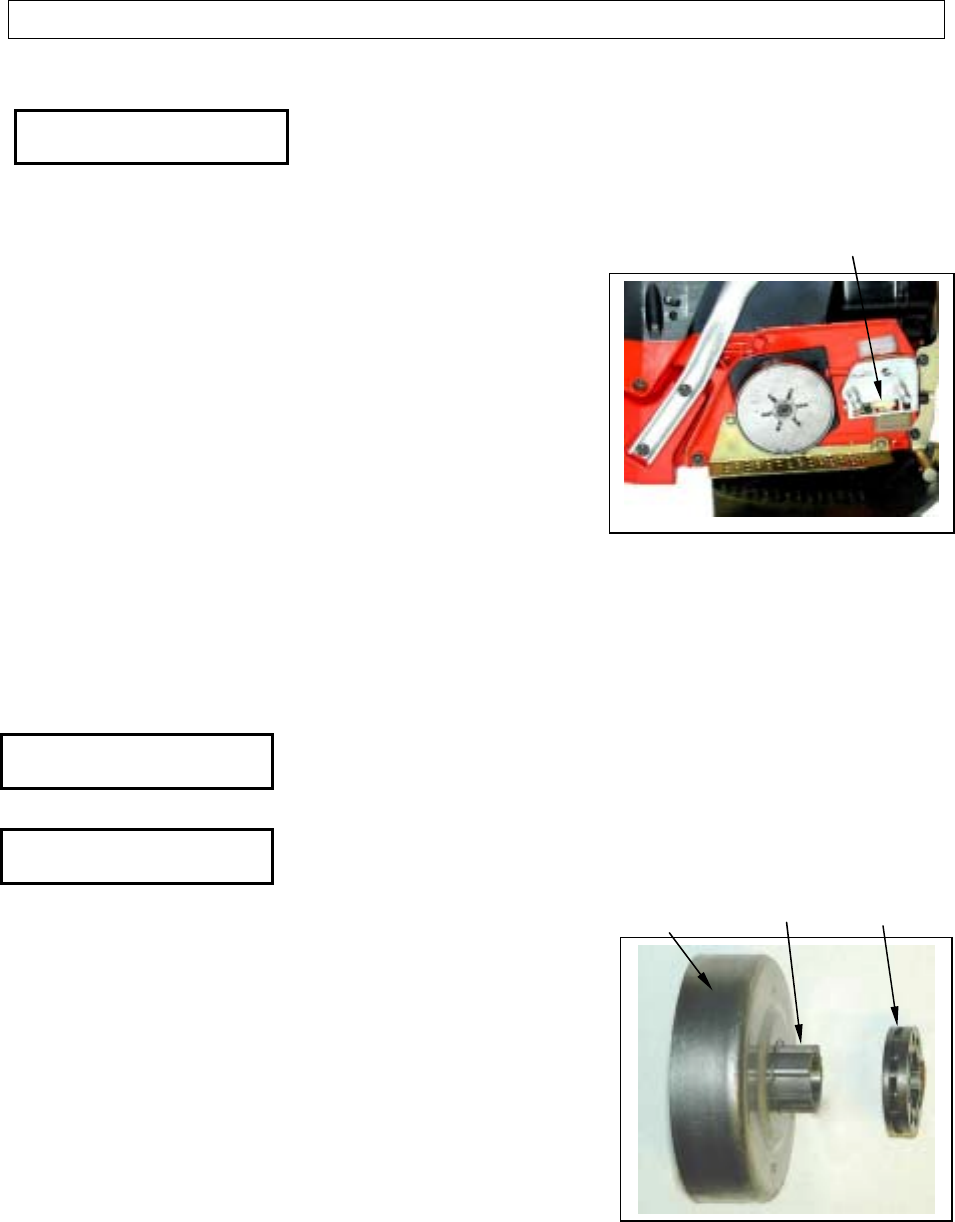

DRIVE SPROCKET

The drive sprocket (rim sprocket) is a wear item and should be

replaced every 2-3 diamond chains.

The needle bearing inside the splined adapter should be greased

regularly and should be replaced with each new clutch cup.

A rim sprocket system (Figure 2) consists of a clutch cup w/

splined adapter and a rim sprocket. When the rim sprocket

wears out, it is the only part that needs to be replaced. The

clutch cup w/ splined adapter is a wear item that needs

replacement after 3 to 5 rim sprockets have been used.

• Inspect the rim the rim sprocket for wear. Replace the rim

sprocket if the drive teeth become pointed.

• Check the drive sprocket bearing by spinning clutch cup.

Replace the bearing if it is worn out.

• The needle bearing on the drive shaft must be greased

regularly, use high quality water-resistant bearing grease.

IMPORTANT

IMPORTANT

IMPORTANT

Figure 2

Splined

Adapter

Clutch

Cu

p

Rim

Sprocket

Chain

Tensioner

Figure 1