— 11 —

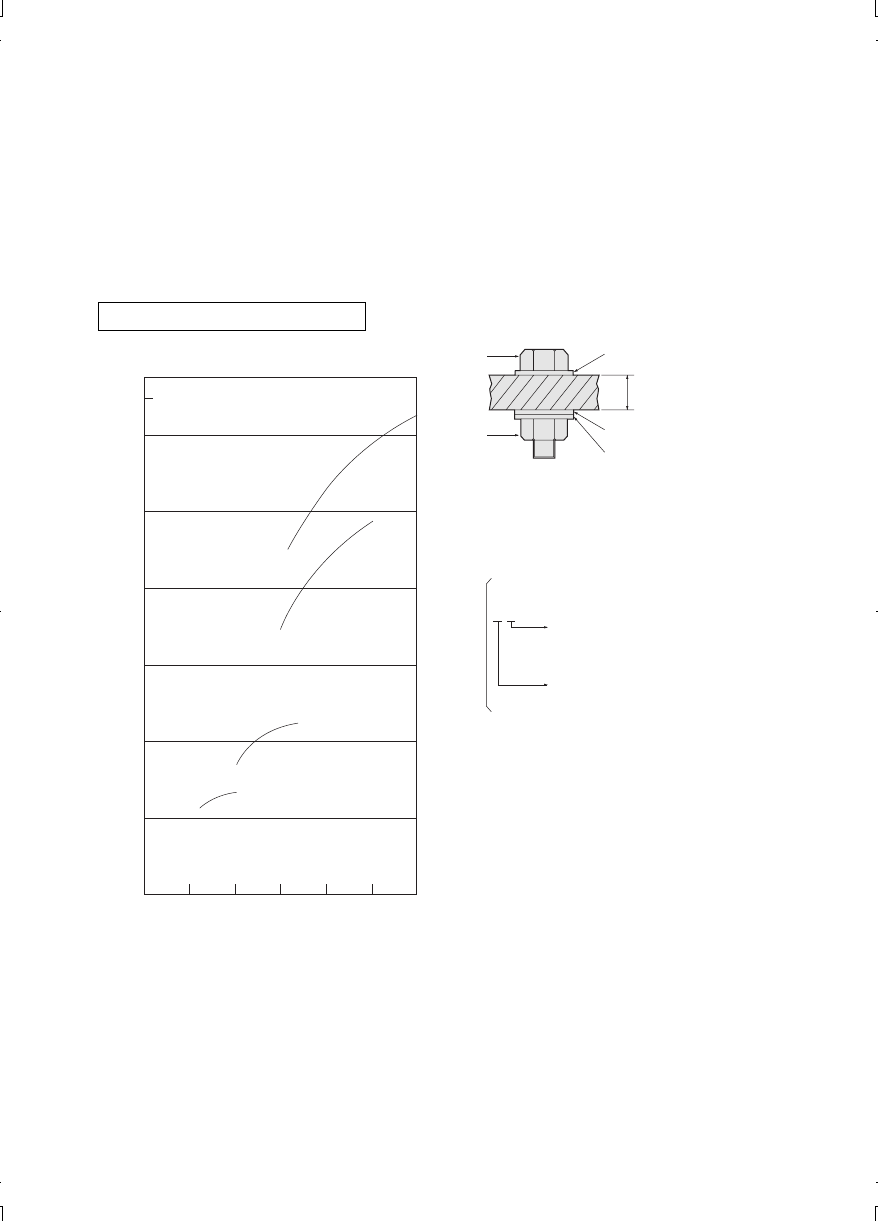

TIGHTENING TORQUE

• The power required for tightening a bolt will vary, according to bolt material and size, as well as the

material being bolted. Choose the length of tightening time accordingly.

Reference values are provided below.

(They may vary according to tightening conditions.)

FACTORS AFFECTING TIGHTENING TORQUE

The tightening torque is affected by a wide variety of factors including the followings. After tightening,

always check the torque with a torque wrench.

1) Voltage

When the battery pack becomes nearly discharged, the voltage decreases and the tightening

torque drops.

Bolt Tightening Conditions

M8, M10, M12, M14 x 25 mm Standard bolt

(Bolt size : Millimeters)

127.4

(1300)

N·m

(kgf-cm)

M14

39.2

(400)

58.8

(600)

78.5

(800)

98.1

(1000)

0.1 0.25 0.5

Tightening time (Sec.)

12

3

117.7

(1200)

Tightening torque

19.6

(200)

M8

M10

M12

Washer

Washer

Spring washer

Steel plate

thickness 10 mm (3/8")

Bolt

Nut

Tightening conditions

*

The following bolts are used.

Standard bolt: Strength type 4.8

High tensile type 12.9

Explanation of the strength type

4.8

Bolt tensile strength 588 N/mm

2

(60 kgf/mm

2

)

Bolt yield point

(80% of tensile strength)

471 N/mm

2

(48 kgf/mm

2

)

EY6535(EU).book Page 11 Tuesday, March 1, 2005 9:36 AM