1 Features of the ANUJ 3000/3500

1

The ANUJ 3000/3500 is an UV curing device that quickly hardens UV resins (inks, adhesives, and coatings)

via irradiation with UV light from an LED light source. The focused application of UV radiation to UV resins

coated on minute surfaces (2 to 3 mm dia.) such as the lenses of CD, MD, and DVD players, and the LCD

panels of notebook PCs, enables precise adhesion.

■High-power irradiation: 10,000 mW/cm

2

(with ANUJ6423 lens)

Higher radiation intensity and a wider range of applications. Shorter production cycles.

■Long LED life: 20,000 hours (LED life: Total irradiation time before UV intensity falls to 70% of

initial value)

At least six times longer LED life than a comparable lamp model, enabling reduced running costs.

■UV curing without temperature increases

Uses a single 365-nm LED UV light source that does not emit any infrared radiation, eliminating the risk of

heat damaging the workpiece.

■UV intensity stabilization

UV intensity is kept constant, even if the ambient or LED temperature changes.

■Easy-to-install LED head

At 12 mm dia. by 50 mm len., the LED is easy to mount on a jig. Mounting the LED head in place reduces

overheating and increases UV intensity.

■No cooling fan, enabling cleanroom use

There is no need to deal with exhaust.

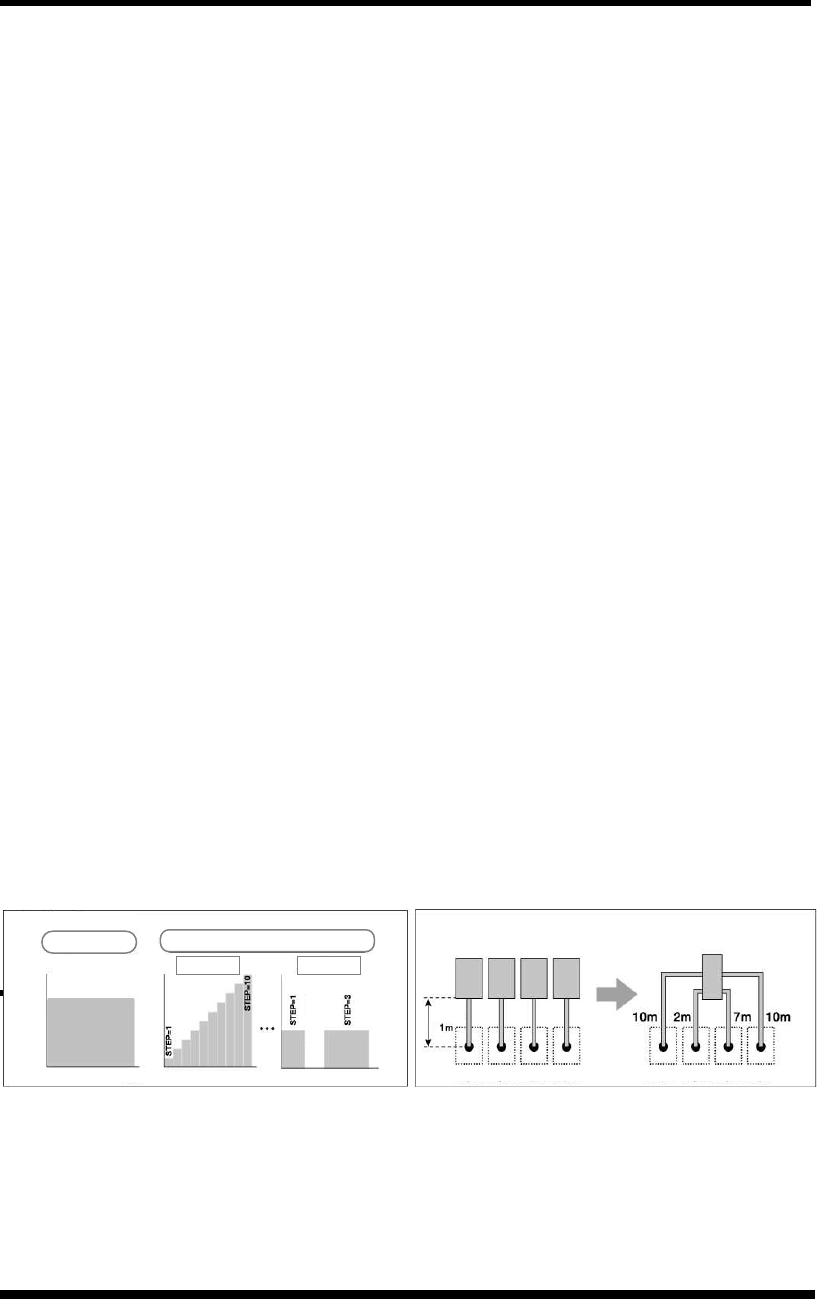

■Programmable UV irradiation with four independently controlled heads

Each LED head can be controlled independently. The heads can also be controlled all together or in

combination. Up to eight different operation programs can be stored for each channel, including one program

for the constant intensity irradiation and seven programs composed of up to 10 steps each.

1 Features of the ANUJ 3000/3500

Up to 7 programs can be set.

Program examples

Simple mode

Program 1

Program 7

Constant

intensity

UV

intensity

Time

Interval (closed)

[Lamp type]

Four units need to be installed

separately for

proce

sses 1 to 4.

Process 1 Process 2 Process 3 Process 4

One controller handles processes

1 to 4.

Process 1 Process 2 Process 3 Process 4

Fiber