HOW TO USE THE PORTA-PLANE

®

MAKING THE CUT

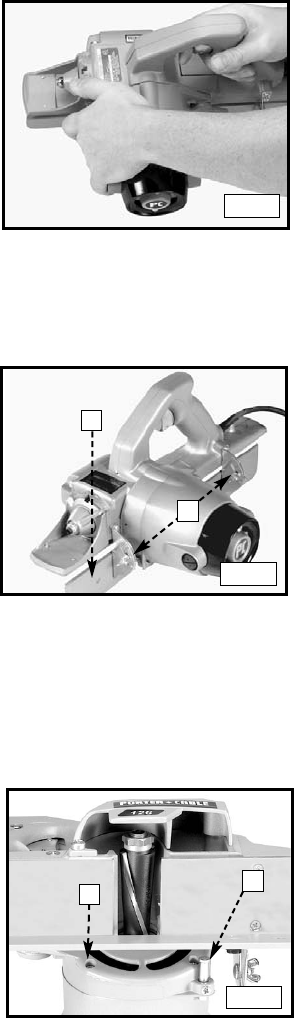

To provide maximum control of the tool,

hold the planer with the right hand on

the handle and the left hand on the front

of the motor housing (Fig. 7). Rest the

thumb on the depth adjusting lever and

wrap the fingers around the motor

housing.

The position of the plane on the work is

important in obtaining optimum results.

Hold the plane shoe and the apron firmly

against the work. At the start of the cut,

place the pressure on the front shoe.

After the plane has entered the work, put pressure on the rear shoe. Follow

through with the plane to the end of the cut and continue the rear pressure until

the cut is complete.

BEVEL CUTTING

The plane may be quickly set for outside

bevel cuts from 0 degrees to 15 degrees

or inside bevel cuts from 0 degrees to

45 degrees. Make the bevel adjustment

by loosening the two wing nuts (A) Fig. 8

on the apron hinges and tilting the apron

(B) until the pointers on the hinges line

up with the desired angle graduations.

Tighten the wing nuts (A) securely. The

beveled cuts are made the same as

regular right-angle cuts. More than one

pass may be necessary, depending on

the width of the bevel. Keep the plane shoe and the apron pressed firmly against

the work during the entire cut. Make each cut for the full length of the board.

APRON STOP STUD

The apron stop stud is located directly behind the front hinge of the apron (A)

Fig. 9 and on the underside of the motor housing (B) Fig. 9, and is held in place

by a screw. This stud is used to produce exact settings of the apron quickly for

repeated cuts of the same angle.

Select the required setting of the

apron and lock it in place with the

thumb screws (A) Fig. 8. With a

screwdriver, turn the screw and

release the stud. Move the stud until

the head rests against the side of the

apron (Fig. 9). Tighten the screw. After

this procedure, the apron can be

adjusted to smaller angles and quickly

re-set to the original angle by simply

moving it back against the apron stop

stud.

11

Fig. 7

B

A

Fig. 8

B

A

Fig. 9