8

3. Start motor by squeezing trigger.

4. Turn the belt aligning screw (A) in

either direction until edge of belt runs

flush with outer edge of rear rubber

covered pulley. The edge of the belt

will extend beyond edge of the front

pulley.

5. Turn motor OFF and allow sander

to come to a COMPLETE STOP

before setting it down.

ATTACHING AND CARE OF

DUST BAG

Models 360, 360VS, 362 and 362VS

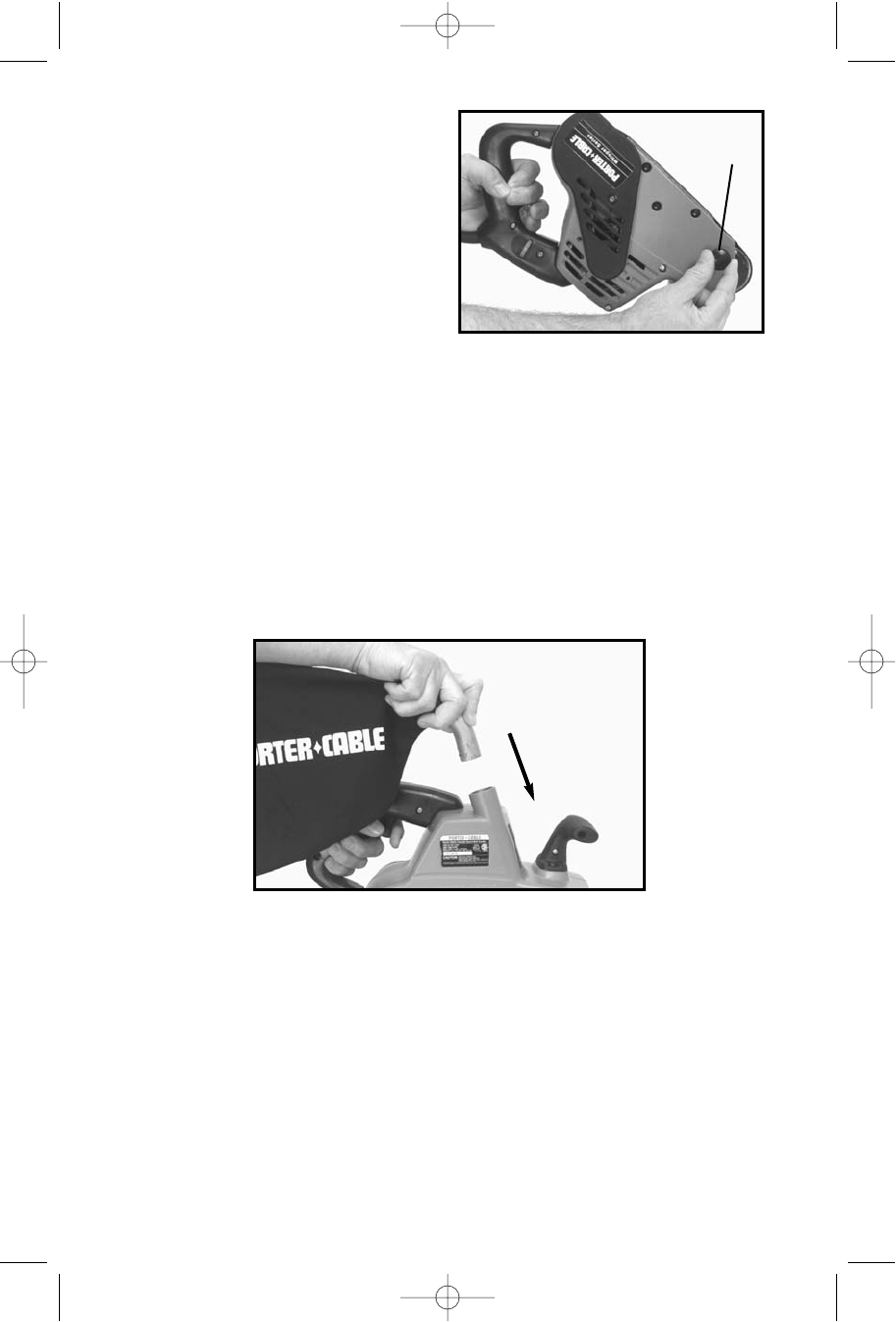

The dust bag is completely assembled at the factory. Attach dust bag to

sander by pushing the dust bag tube into the sander vacuum housing (see Fig.

4).

For most efficient operation, empty the dust bag when it is not more than half

filled. To remove, grasp dust bag tube where it enters vacuum housing and

pull straight out. Unzip rear of bag and shake out dust. Occasionally turn bag

inside out and brush the dust accumulations from the inside.

CAUTION: Do not operate sander without dust bag or a dust

collection hose attached.

OPERATION

SELECTING AN ABRASIVE BELT

The principle abrasive material used on belts for machine sanding are aluminum

oxide and silicon carbide. The first is not as hard as the second, but is tougher

and more suited for woods and soft (non-ferrous) metals. Silicon carbide is

extremely hard and is best suited for surfacing stone, marble and glass.

Abrasives are classed as open-coated (spaced) or closed-coated, meaning

that the grits are spaced apart or close together. Closed coatings provide

hard, fast cutting action for hardwoods and dense metals while the open

coatings are more suited to soft materials and painted surfaces.

Fig. 4

Fig. 3

A

899713 - 04-12-02.qxd 9/23/02 1:50 PM Page 8