10

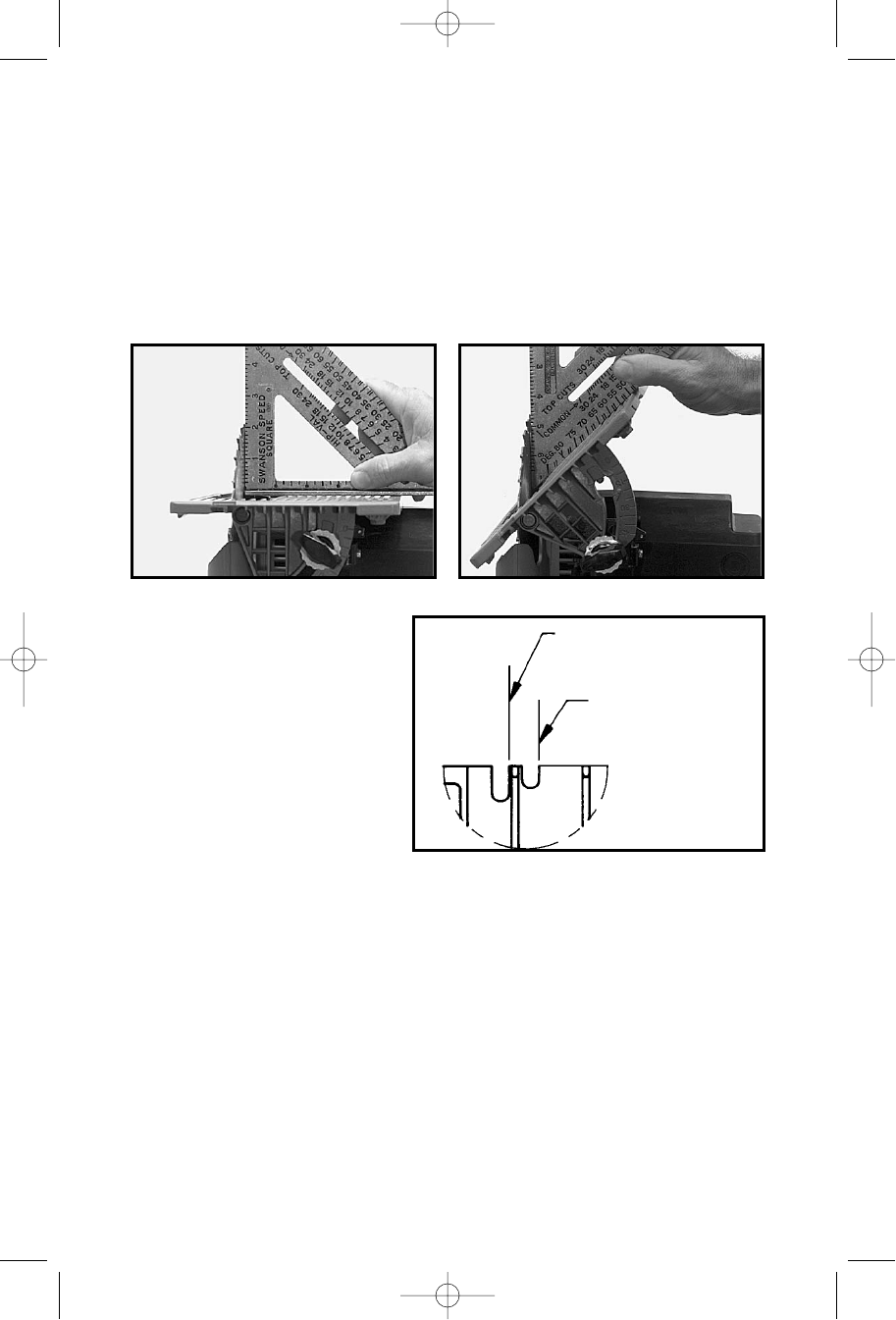

TO ADJUST 90° POSITIVE STOP

1. CAUTION: DISCONNECT TOOL FROM POWER SOURCE.

2. Set bevel stop sleeve to normal position (see Fig. 6).

3. Loosen bevel adjustment knob (A) Fig. 5, and position base for 90° cut

being sure that the bevel stop sleeve is against the 90° stop screw.

4. Turn saw upside down, retract telescoping guard and check squareness

of blade as shown in Fig. 7.

5. If adjustment is necessary, loosen bevel adjustment knob, keeping bevel

stop sleeve in contact with stop screw, turn stop screw (see Fig. 6) until

squareness is obtained.

TO ADJUST 45° BEVEL

POSITIVE STOP

1. CAUTION: DISCONNECT

TOOL FROM POWER

SOURCE.

2. Set bevel stop sleeve to

normal position (see Fig. 6).

3. Loosen bevel adjustment

knob (A) Fig. 5, and position

base for 45° cut being sure that

the bevel stop sleeve is against

the 45° stop screw.

4. Turn saw upside down, retract telescoping guard and check 45° angle as

shown in Fig. 8.

5. If adjustment is necessary, loosen bevel adjustment knob and turn stop

screw (see Fig. 6) until angle is correct.

LINE-OF-CUT INDICATOR

Line-of-cut indicator slots (see Fig. 9), are provided at the front of the saw

base. The left slot is used to follow a line when making a 90° cut. The right slot

is used to follow a line when making a 45° cut.

BLADE WRENCH STORAGE

Blade wrench storage is provided in the bottom of the saw handle (see Fig.

10). Position the handle end of the blade wrench into the storage slot and

push forward until seated.

Fig. 9

SIGHT THIS EDGE

FOR 90° CUTS

SIGHT THIS EDGE

FOR 45° CUTS

VIEWED FROM

OPERATOR’S

POSITION

Fig. 7 Fig. 8

900004 - 06-07-02.qxd 6/24/02 1:13 PM Page 10