12-ENG

D26998

How to Use Your Unit

How to Stop:

1. See the engine manufacturer's manual for the procedure to safely shut

down the gasoline engine. Turning the gasoline engine off will turn off the air

compressor as well.

Before First Start-up

Break-in Procedure

Serious damage may result if the following break-in

instructions are not closely followed.

This procedure is required when:

1. Before the air compressor is used for the first time.

2. When the unloader valve is replaced.

3. When a complete compressor pump is replaced.

The procedure:

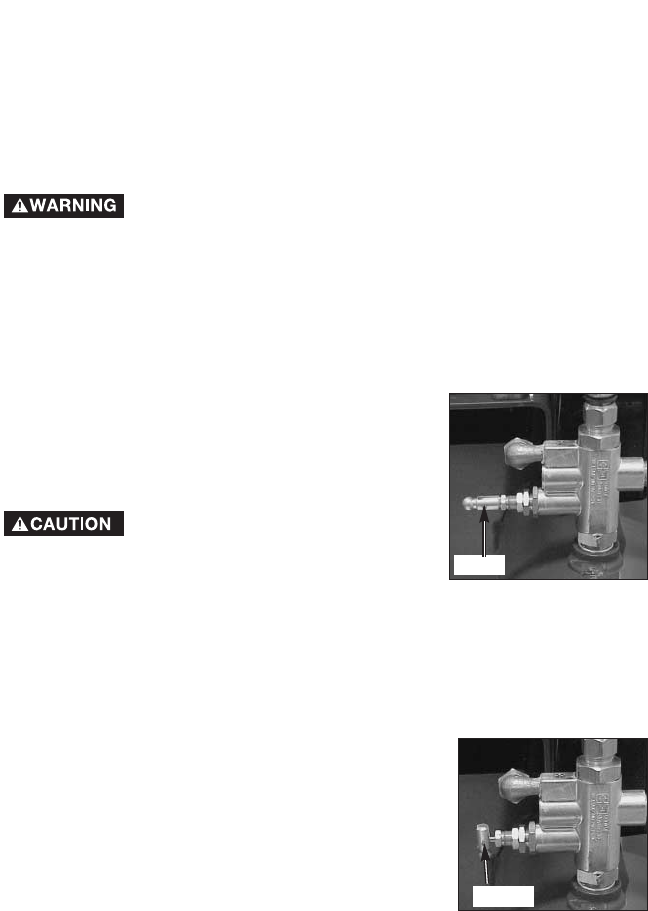

1. To prevent pressure from building up in the air tanks during this break-in

period, you must open the unit's unloader valve. Place unloader valve in

“Open” position as shown.

2. Open the pressure regulator. Pull regulator

knob and rotate clockwise until it stops.

3. Start engine. See engine manual supplied by

engine manufacturer for correct procedure.

The air compressor is top

heavy. Make sure the unit is in

a stable position and will not tip before pulling

the starter cord of the engine.

4. Make sure the unloader valve is in the “Open” position to prevent tank

pressure buildup.

5. Run the air compressor for 30 minutes to seat the rings and lubricate all

the internal surfaces. Make sure there is no pressure build up in the tank by

observing the reading on the tank pressure gauge.

6. Place unloader valve in the “Closed” position as shown.

7. Close the pressure regulator. Rotate the regulator

knob counter-clockwise to its built-in stop and

push knob in to lock in place. This will allow air to

build pressure in the air tanks.

NOTE: When the air tank is pressurized, the tank pres-

sure gauge will indicate the pressure available in the air

tank and the gasoline engine will reduce its speed to

idle and keep running. The pressurization of the air tank

will be adjusted automatically by the "reset" and "blow

off" setting of the unloader valve. When the pressure in

the air tank drops to the "reset" value, the gasoline engine will increase its rpm

to operate the compressor and pressurize the tanks. When the pressure in the

air tank increases to the "blow off" value, the engine rpm will drop to idle.

NOTE: Consult the engine manufacturer's manual for the proper engine

break-in running time and oil change interval for the engine used on your

air compressor as well as other engine maintenance requirements.

Open

Closed