14

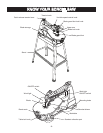

Fig. G

3. Tilt the table to 0° and tighten the table lock knob

(6-Fig. H). Loosen the lower blade holder lock knob

(7-Fig. G) under the table on the left side of the lower

blade holder (8-Fig. G) by turning counterclockwise.

4. Pull down on the arm, and then remove the blade

from the upper and lower blade holders by pulling

forward and lifting the blade through the access hole

(9) in the table (10). (Fig. H)

Fig. H

Plain-end blade installation (FIG. H, I, J)

In order to avoid uncontrollable lifting of the workpiece,

the teeth of the blade should ALWAYS point downward.

1. Install the new blade (1) through the access hole (9)

in the table (10) with teeth pointing down. (Fig. H)

2. Insert the new blade (1) into the lower blade holder

slot (11), then tighten the lower blade holder knob (7).

(Fig. I)

Fig. I

3. Tilt the table to 0° bevel setting and lock the bevel

knob (6). (Fig. H)

4. Insert the other end of the blade into the upper blade

holder slot (12-Fig. I) and then tighten the quick

release tension lever (14-Fig. J).

NOTE:

●

Apply slight downward pressure against the upper

arm (3) when installing the blade into the upper blade

holder. (Fig. I)

●

Clamp plain-end blades more tightly by using a hex

wrench through the screw (13).

5. Tighten the tension on the blade by turning the

tension knob (15) clockwise. Check the tension on

the blade. If too loose, turn knob clockwise. (Fig. J)

Overtightening blade will cause blade breakage.

NOTE: The quick release lever must always be down

to make tension adjustments. Release the quick

release lever only during blade changing operations.

If the blade is tightened too tight, the lever will be difficult

to lower and could result in damage to the blade holder

or arm assembly.

Fig. J

PIN-END BLADE REMOVAL AND INSTALLATION

To prevent personal injury, always turn the saw

OFF and disconnect the plug from the power outlet

before changing blades or making adjustments.

Pin-end type blades are thicker for stability and faster

assembly. These blades are used whenever faster

cutting on a variety of materials and 3/4 in. (19 mm)

thickness or greater are required. Use whenever less

precision or thicker kerf cutting is acceptable.

NOTE: When installing Pin-end blades, the set screws

located on the upper and lower blade holders should

not be over or under tightened. The slot must be slightly

wider than the thickness of the blade. After the blade

is installed, the blade tension mechanism will keep the

Pin-end in place.

14

15

WARNING

!

5

3

1

4

8

7

CAUTION

12

1

4

11

7

3

13

1

6

9

10

CAUTION