16

Fig. O

SAWDUST BLOWER (FIG. P)

The sawdust blower (4) should be positioned to point to

the blade and workpiece to blow sawdust out of the line-

of-sight when cutting. It is not designed to blow all of the

sawdust off the table.

Fig. P

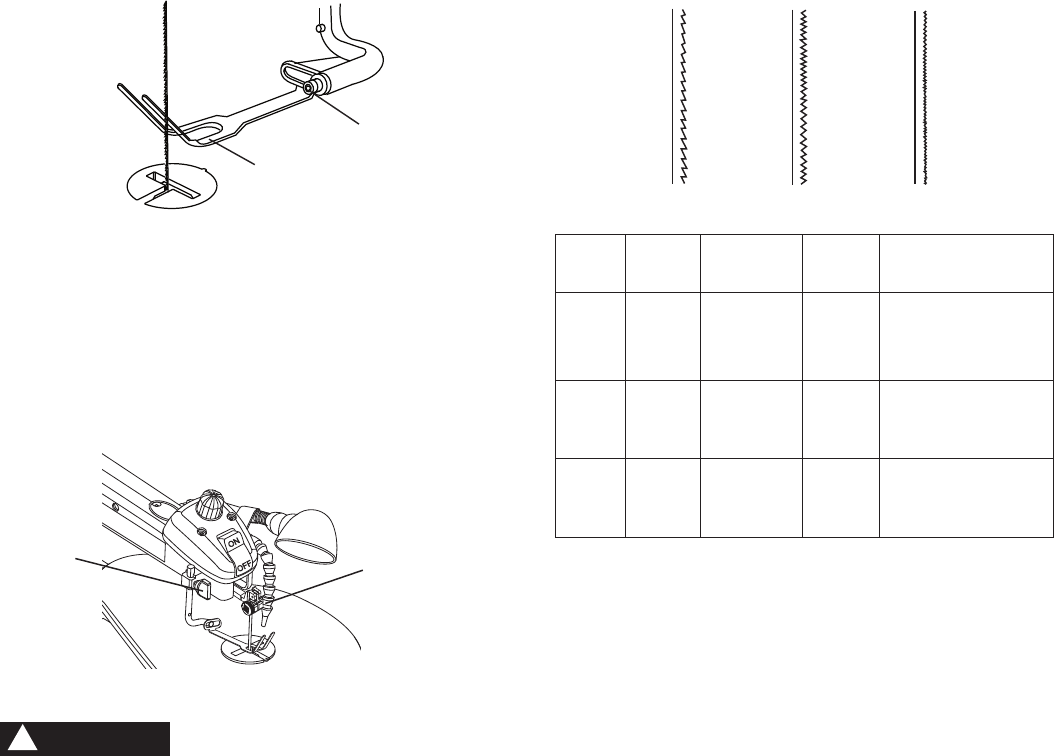

BLADE SELECTION (FIG. Q)

To avoid injury from accidental starting, always turn

the switch OFF and unplug the scroll saw before

moving, replacing the blade or making adjustments.

This scroll saw accepts 5-in. (127-mm) length blades

with a wide variety of blade thickness and widths. The

type of material and cutting operations (size of radius or

curve) will determine the number of teeth per inch. As

a rule, always select the narrowest blades for intricate

curve cutting and the widest blades for straight and

large curve cutting operations.

The following table represents suggestions for various

materials. When purchasing blades, refer to the back of

the package for the best use of blades and speeds on

various materials.

Use this table as an example, but practice and your own

personal preference will determine the best selection

method.

1

2

WARNING

!

Fig. Q

TEETH/

INCH

TPI

BLADE

WIDTH

INCH

BLADE

THICKNESS

INCH

BLADE/

SPM MATERIAL CUT

9.5-15

0.110

(2.8 mm)

0.018

(0.46 mm)

400-1200

Medium turns on 1/4

in. (6.35 mm) to 1-3/4

in. (44.45 mm) wood,

soft metal, hardwood

15-28

.055-.110

(1.4-2.8 mm)

.010-.018

(0.25-0.46 mm)

800-1800

Small turns on 1/8 in.

(3.18 mm) to 1-1/2 in.

(38.1 mm) wood, soft

metal, hardwood

30-48

.024-.041

(0.6-1.0 mm)

.012-.019

(0.3-0.48 mm)

Varies

Non-ferrous

metals/hardwoods

using very slow

speeds

NOTE: When using blades, sometimes speeds must

change to compensate for smaller curves, radii or

smaller diameters. Thinner blades will have more

possibilities for blade deflection when cutting angles

which are not perpendicular to the table. Read BASIC

SCROLL SAW OPERATION for more suggestions.

NOTE: The blade must be installed with the teeth

pointing downward, to prevent the workpiece from being

pulled upward by the saw blade action.

9.5-15

15-28

30-48

4

3