31

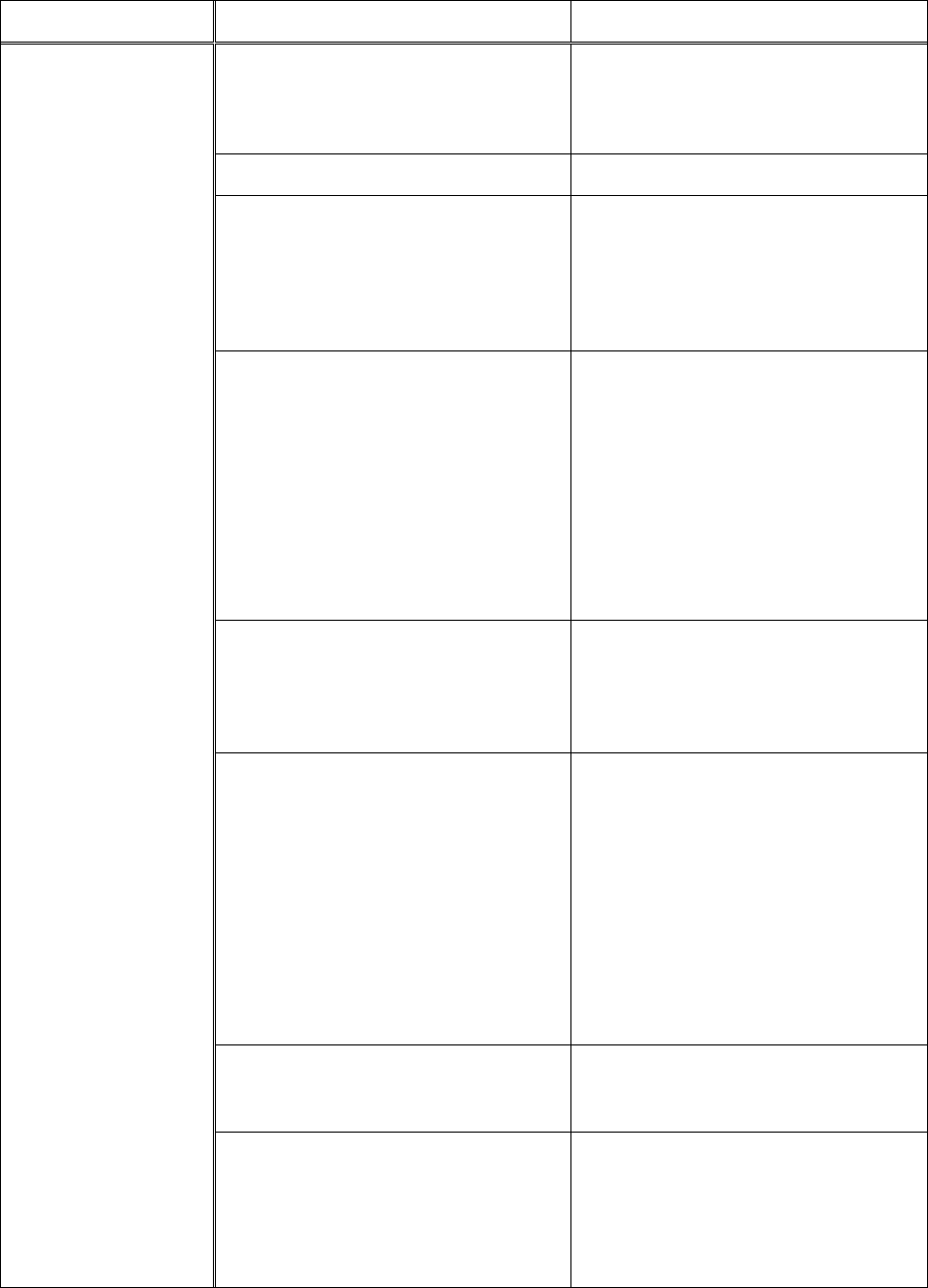

Troubleshooting – Mechanical and Electrical Problems

Trouble Probable Cause Remedy

No incoming power.

Verify machine is connected to power

source. Make sure START button is

pushed in completely, and the STOP

button is disengaged. See page 21.

Cord damaged. Replace cord.

Overload automatic reset has not

been reset.

Remove the switch plate from the rear

of the column (see page 14) and reset

the overload by pushing in completely

the OFF (red) button on the magnetic

switch. If problem persists, check amp

setting on the motor starter.

Band Saw frequently trips.

One cause of overloading trips which

are not electrical in nature is too

heavy a cut. The solution is to reduce

feed pressure into the blade. If too

heavy a cut is not the problem, then

check the amp setting on the overload

relay. Match the full load amps on the

motor as noted on the motor plate. If

amp setting is correct then there is

probably a loose electrical lead.

Check amp setting on motor starter.

Building circuit breaker trips or fuse

blows.

Verify that band saw is on a circuit of

correct size. If circuit size is correct,

there is probably a loose electrical

lead. Check amp setting on motor

starter.

Switch or motor failure (how to

distinguish).

If you have access to a voltmeter, you

can separate a starter failure from a

motor failure by first, verifying

incoming voltage at 220+/-20 and

second, checking the voltage

between starter and motor at 220+/-

20. If incoming voltage is incorrect,

you have a power supply problem. If

voltage between starter and motor is

incorrect, you have a starter problem.

If voltage between starter and motor

is correct, you have a motor problem.

Motor overheated.

Clean motor of dust or debris to allow

proper air circulation. Allow motor to

cool down before restarting.

Machine will not

start/restart or

repeatedly trips

circuit breaker or

blows fuses.

Motor failure.

If electric motor is suspect, you have

two options: Have a qualified

electrician test the motor for function

or remove the motor and take it to a

qualified electric motor repair shop

and have it tested.