15

1. Disconnect machine from power source.

2. Remove the belt guard so that you can

rotate the cutterhead by turning the motor

pulley or by moving the drive belt. Do not

grab the cutterhead itself to rotate it.

3. Remove the old knives by loosening gib

screws with an 8mm wrench, and allowing

the springs to push the knife upward.

Remove knife and gib.

4. Clean the gib and the knife slot. Sandwich

new knife and gib together and drop into

slot. Make sure the knife is oriented properly

as shown in Figure 16.

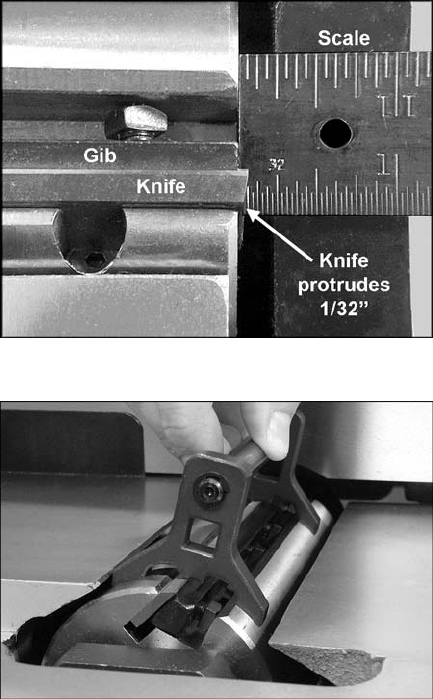

IMPORTANT: To position the knives for rabbet

cuts, take a shop scale with 1/32" graduations

and place it against the end of the cutterhead.

See Figure 17. Slide the knife out until it is at the

1/32" mark on the scale; that is, the knife will

now be 1/32" beyond the edge of the

cutterhead. The gib should remain in normal

position, even with the edge of the cutterhead.

This adjustment will ensure that the knife clears

the end of the gib and cutterhead, and has good

contact with the workpiece. (See under “Basic

Jointer Operation” for further information on

rabbeting procedures.)

5. The height of the knife in the slot, both for

rabbeting and normal jointer work, must now

be set properly, to ensure correct operation

as well as minimize the hazard of kickback.

Proceed as follows:

6. Rotate the cutterhead (using the belt or

pulley) until the tip of the knife is at the top

of the cutterhead arc. Place the knife setting

gauge (Figure 18) over the cutterhead so

the tip of the knife contacts the center of the

gauge, and all four "feet" of the gauge rest

firmly upon the cutterhead, as the knife is

pushed down into its slot. The gauge will

position the knives at approximately .015"

above the cutterhead. Knife height should

not vary more than .002-.003" across the

length of the cutterhead.

7. Tightening the gib screws should be done in

increments, to prevent any distortion to the

cutterhead or buckling of knives. While

holding the gauge down on one knife, snug

down the five gib screws, beginning with the

center screw and working your way to the

ends. Do not fully tighten yet.

8. Rotate the cutterhead to the next slot and

repeat steps #6 and #7, only making the

knives snug.

9. Repeat for the third knife.

Figure 17

(straight cutterhead only)

Figure 18

(straight cutterhead only)