7

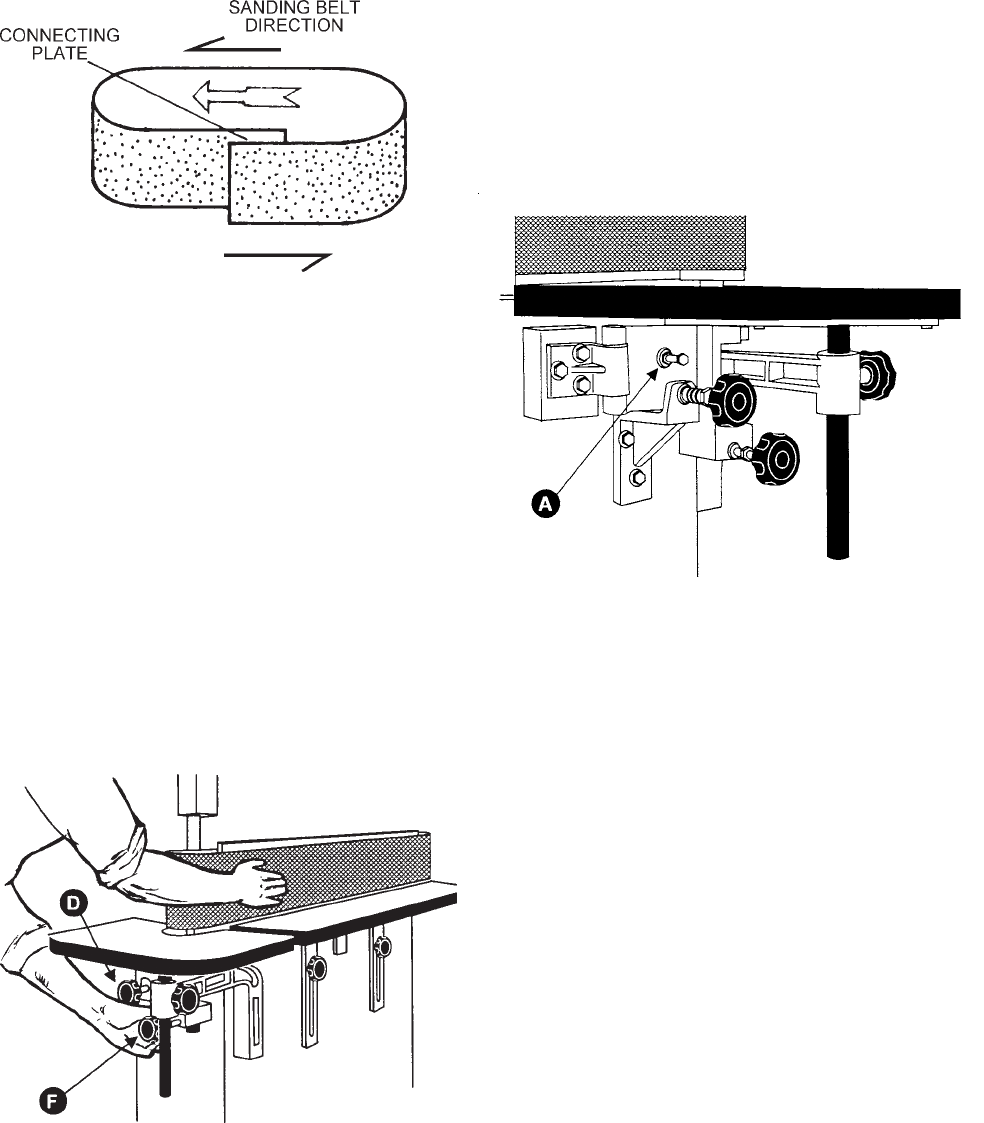

NOTE: Identify the sanding belt direction before you

install the belt, because the belt's rotational direction

must be the same as the machine. An arrow on the

reverse side of the belt shows the proper direction

and should match the arrow direction on the machine

guard. If the belt has no arrow indicator, find the

joint of the belt (where it is layered) and install it ac-

cording to Figure 3.

FIGURE 3

4. Place the new sanding belt between the con-

tact wheel and idler pulley, then adjust the tension

adjustment knob (D). Counterclockwise will maxi-

mize the tension, clockwise will minimize it.

5. Check that the new belt is tracking correctly by

rotating it with one hand, Figure 4, and use your other

hand to make any adjustments to the track adjust-

ment knob (F). To lower the abrasive belt, rotate the

track adjustment knob clockwise. To raise it, rotate

counterclockwise.

NOTE: The track adjustment mechanism is

very sensitive - make these corrections gently.

When properly adjusted, the sanding belt should keep

the same steady level during rotation without mov-

ing too high or too low.

FIGURE 4

6. Replace safety guard (B), close dust hood and

re-tighten knobs (A).

7. Turn machine on and off quickly several times

to check that the sanding belt rotation is normal and

that it tracks properly. If not, repeat the above pro-

cedure.

SANDING BELT TENSION SPRING

FATIGUE COMPENSATION

Adjustment of the sanding belt will cause spring fa-

tigue when used for a long period. If this happens,

it's not necessary to change the spring. Simply ro-

tate the tension adjustment screw (A), Figure 5, clock-

wise until you achieve the proper tension compen-

sation.

FIGURE 5

FRONT WORK TABLE INCLINATION

Using the inclined table method on this edge sander

may give you better sanding surface contact, de-

creased sanding marks and burr residue, with re-

sults equal to that of an oscillating sanding machine.

To adjust the front work table:

1. Loosen the two fixed knobs (A), Figure 6.

2. Raise the front work table (B) by rotating the

adjustment knob (C) and incline it to the degree de-

sired.

3. Re-tighten the fixed knobs (A).