11

Grounding Instructions

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

As received from the factory, the PF-BS Stock

Feeder will run on either 230 volt or 460 volt,

depending upon your particular model. Make

sure the voltage of your power supply matches

the specifications on the motor plate of the

machine.

You may either connect an appropriate UL/CSA

listed plug or “hard-wire” the machine directly to

a control panel. If hard-wired to a panel, make

sure a disconnect is available for the operator.

The Stock Feeder must comply with all local and

national codes after being wired. If it is to be

hard-wired, make sure the fuses have been

removed or the breakers have been tripped in

the circuit to which the Stock Feeder will be

connected. Place a warning placard on the fuse

holder or circuit breaker to prevent it being

turned on while the machine is being wired.

Refer to “Electrical Connections” on page 23 for

connecting the motor leads.

This machine must be grounded. In the event of

a malfunction or breakdown, grounding provides

a path of least resistance for electric current, to

reduce the risk of electric shock to the operator.

Improper connection of the equipment-

grounding conductor can result in a risk of

electric shock. The conductor, with insulation

having an outer surface that is green with or

without yellow stripes, is the equipment-

grounding conductor. If repair or replacement of

the electric cord or plug is necessary, do not

connect the equipment-grounding conductor to a

live terminal.

Repair or replace a damaged or worn cord

immediately.

Extension Cords

If an extension cord is necessary make sure the

cord rating is suitable for the amperage listed on

the machine's motor plate. An undersize cord

will cause a drop in line voltage resulting in loss

of power and overheating.

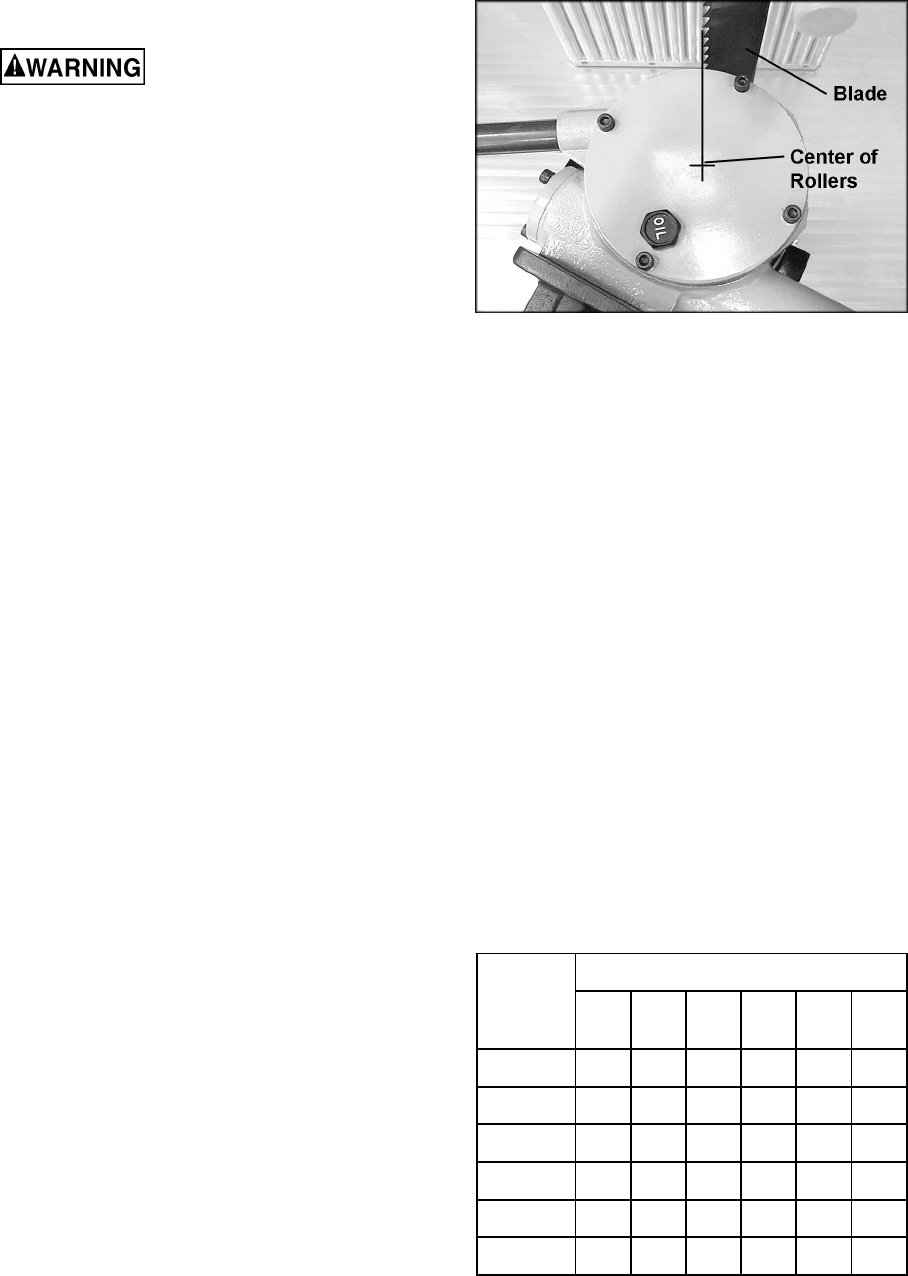

The chart in Figure 9 shows the correct size

cord to use based on cord length and motor

plate amp rating. If in doubt, use the next

heavier gauge. The smaller the gauge number

the heavier the cord.

Figure 8

Recommended Gauges (AWG) of Extension Cords

Extension Cord Length *

Amps

25

feet

50

feet

75

feet

100

feet

150

feet

200

feet

< 5 16 16 16 14 12 12

5 to 8 16 16 14 12 10 NR

8 to 12 14 14 12 10 NR NR

12 to 15 12 12 10 10 NR NR

15 to 20 10 10 10 NR NR NR

21 to 30 10 NR NR NR NR NR

*based on limiting the line voltage drop to 5V at 150% of the

rated amperes.

NR: Not Recommended.

Figure 9