9

Assembly and Installation

Tools needed for assembly:

8.5mm drill bit

M10 x 1.5P tap

17mm wrench

Remove the clear plastic from around the Stock

Feeder and Fence Assembly.

Exposed metal surfaces have been given a

protective coating at the factory. This should be

removed with a soft cloth moistened with a good

commercial solvent, such as kerosene or

mineral spirits. Do not use acetone, gasoline, or

lacquer thinner for this purpose. Do not get

solvents near plastic or rubber parts, and do not

use an abrasive pad because it may scratch

metal surfaces.

The Stock Feeder should be mounted to a band

saw table in a well-lit area. Leave enough space

around the work area for loading and off-loading

stock and general maintenance.

The Stock Feeder and the

band saw to which you are mounting it

should both be disconnected from power

during installation.

Follow these steps to assemble and install the

Stock Feeder and Fence:

Use the diagram in Figure 1 (page 8) to identify

the proper location for marking the hole patterns

on the band saw table. Do not drill and tap the

holes yet, only mark them.

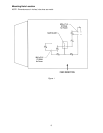

Mounting the Fence

1. The fence must be parallel with the blade

for accurate cuts as well as for safety. To

achieve this, mark the location of the near

hole for the Fence based on the dimensions

in Figure 1, page 8. Drill and tap the near

hole then place the fence over the hole

pattern. Insert an M10 x 30 hex cap screw

with lock washer into the near hole, as

shown in Figure 2. With a 17mm wrench,

make the screw snug. Do not tighten

completely.

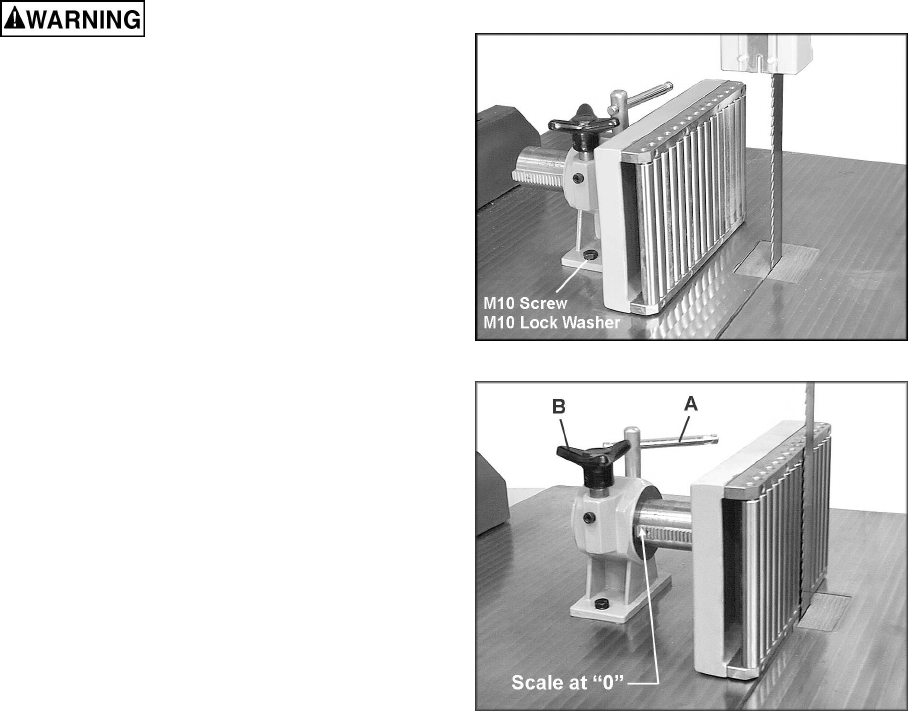

2. Loosen the handle (A, Figure 3) and rotate

the knob (B, Figure 3) until the fence is right

up to the blade; that is, the scale on the

fence should be at “0”.

Figure 2

Figure 3