15

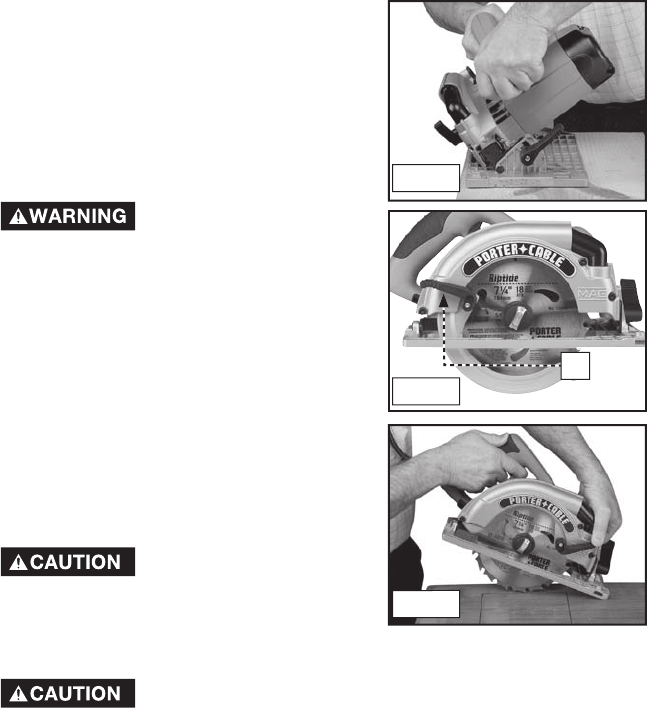

BEVEL CUTTING

Bevel cuts are made in the same manner as

crosscuts and rip cuts. The difference is that

the blade is set at an angle between 0° and

45° (Fig. 19).

The bevel cut made at an angle to the edge

of a board is called a compound cut. Certain

compound cuts may require you to manually

retract the telescoping guard to allow the blade

to enter into and/or through the cut.

Use the lever (A) Fig.

20 provided on the

telescoping guard when you have to retract

the telescoping guard manually.

POCKET CUTS (PLUNGE CUTTING)

A pocket cut is one which must be made

inside the area of the workpiece and not

starting from the edge. Mark the area clearly

with lines on all sides. Start near the corner of

one side and place the front edge of the saw

base firmly on the workpiece. Hold the saw up

so that the blade clears the material. Confirm

that you have adjusted the blade properly for

the depth-of-cut. Push the telescoping guard

lever all the way back so the blade is exposed

(Fig. 21).

Keep your hands and fingers

away from the blade.Start

the motor and lower the blade into the work.

After the blade has cut through, and the base

rests flat on the work, follow the line to the

corner.

Let the saw come to a complete stop before removing it from

the workpiece.

Use a keyhole or bayonet saw to cut clean corners.

Fig. 19

Fig. 20

A

Fig. 21