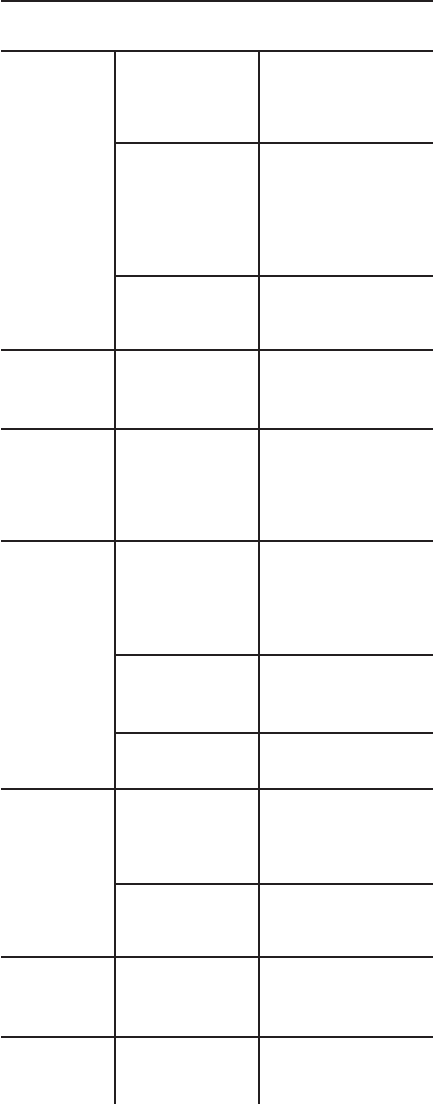

20

101274

PROBLEM

Piston hangs

out of muzzle.

Overdriven fas-

tener.

Piston jammed.

Expended load

will not extract.

Reduction or

loss of power.

Reduction or

loss of power

Tool does not

completely de-

press.

Tool does not

fire.

POSSIBLE

CAUSE

Tool overdriven.

Piston not properly

assembled in rela-

tion to barrel screw.

Broken piston.

Excessive power.

Overdriving of fas-

tener (see above).

Dirty or damaged

chamber.

Broken ejector.

Pins being used are

over 2

1

/

2

" long.

Piston not returning

to full rear position.

Worn piston ring or

broken piston.

Misassembled or

damaged breech

and firing pin parts.

Failure of tool to de-

press completely.

REMEDY

Tap piston on a hard surface

until piston is pushed back

into the muzzle (see

Overdriven Fastener

below).

Remove barrel assem-

bly. Follow instructions

for barrel replacement

(see page 17). Replace

all damaged or missing

parts.

Replace barrel assem-

bly or take tool to your

distributor.

Change either to next

lower powder load or next

longer length fastener.

Remove barrel assem-

bly. Follow instructions

for barrel replacement

(see page 17). Replace

other parts if damaged.

Clean chamber. If loads

will not chamber with

slip-fit or extraction dif-

ficulties continue, take

tool to your distributor.

Replace barrel assem-

bly or take tool to your

distributor.

Use proper pin size.

Barrel must be snapped

to the full extended posi-

tion to properly position

piston against breech.

Replace barrel assem-

bly or take tool to your

distributor.

Remove breech and

check all parts for cor-

rect fit assembly.

See data listed under

Tool does not completely

depress,

above.

Troubleshooting Guide