10

11

FEATURES

KNOW YOUR AIR COMPRESSOR

See Figure 2.

Before attempting to use this product, familiarize yourself

with all operating features and safety rules.

BUILT-IN CORD WRAP

A built-in cord wrap is provided for convenience in moving

and storing the unit.

DRAIN VALVES

A drain valve is located on each tank for draining condensa-

tion to help prevent tank corrosion.

HANDLE

The handle of your air compressor lifts up for use and folds

down for storage or transportation.

PRESSURE REGULATOR KNOB

Use the pressure regulator knob to adjust the amount of

air being delivered through the hose. Pressing down on the

knob will lock it into place. This prevents movement of the

knob caused by vibration during use.

REGULATOR PRESSURE GAUGE

The current line pressure is displayed on the regulator pres-

sure gauge. This pressure can be adjusted by rotating the

pressure regulator knob.

SAFETY VALVE

The safety valve is designed to automatically release air if

the air receiver pressure exceeds the preset maximum.

TANK PRESSURE GAUGE

The tank pressure gauge indicates the pressure of the air

in the tank.

UNPACKING

This product has been shipped completely assembled.

n Carefully remove the air compressor and any accessories

from the box. Make sure that all items listed in the packing

list are included.

n Inspect the air compressor carefully to make sure no

breakage or damage occurred during shipping.

n Do not discard the packing material until you have care-

fully inspected and satisfactorily operated the product.

n If any parts are damaged or missing, please call

1-866-539-1710 for assistance.

PACKING LIST

Air Compressor

Oil Dipstick

Operator’s Manual

WARNING:

If any parts are damaged or missing do not operate

this tool until the damaged or missing parts are

replaced. Failure to do so could result in possible

serious personal injury.

WARNING:

Do not attempt to modify this tool or create

accessories not recommended for use with this

tool. Any such alteration or modification is misuse

and could result in a hazardous condition leading

to possible serious personal injury.

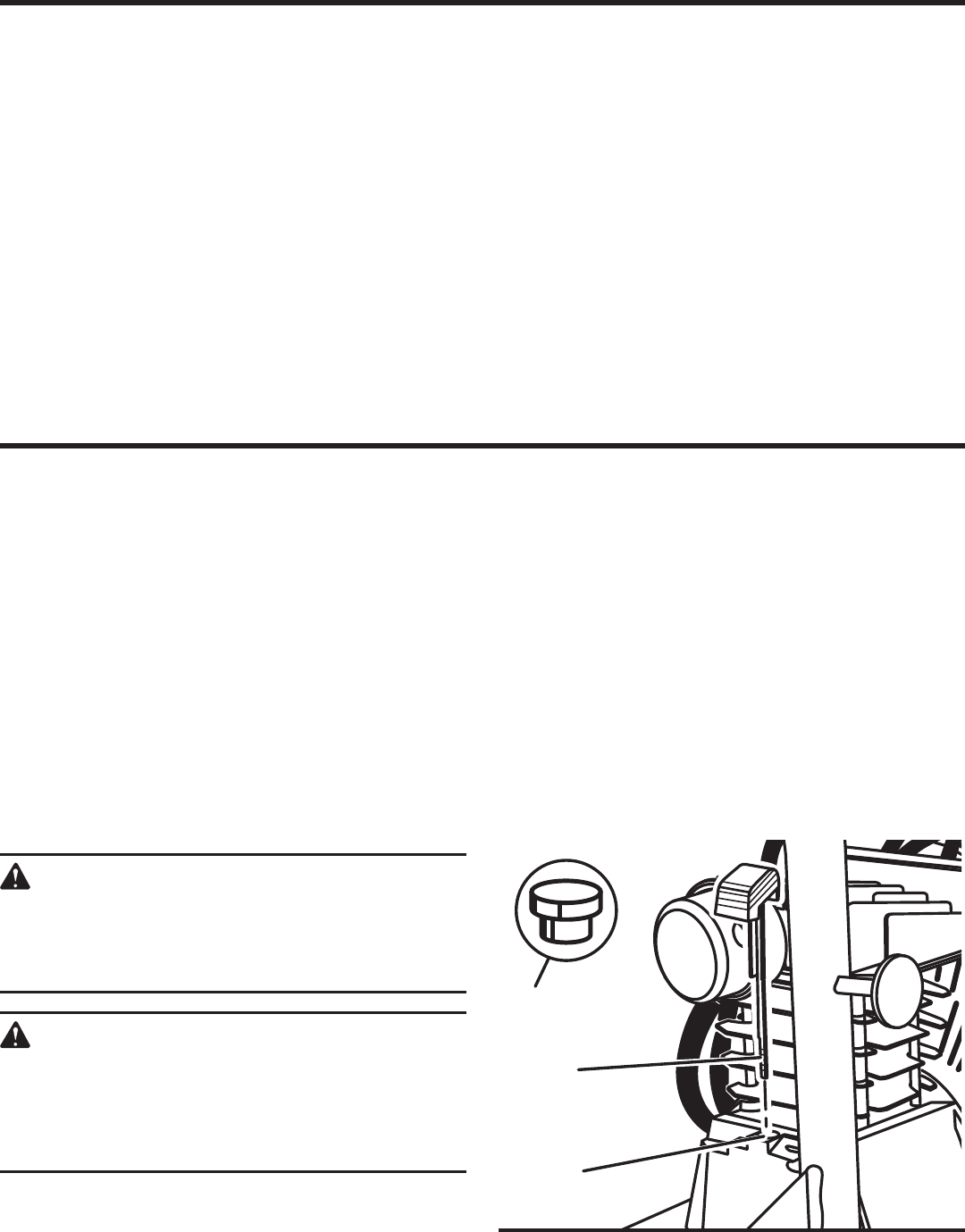

ASSEMBLY

Fig. 3

INSTALLING THE DIPSTICK

See Figure 3.

To prevent oil from spilling during shipping, the air compres-

sor has a plug installed in the oil fill hole. Before using the

unit the first time, replace the plug with the oil fill dipstick

and check the oil level.

n Remove the plug from the oil fill hole.

n Insert the dipstick into the oil fill hole.

n Remove the dipstick and check the oil level, making sure

the oil registers between the MIN and MAX reference lev-

els on the dipstick. If the level does not register between

those areas, refer to Checking the Oil in the Operation

section of this manual.

n Replace the dipstick.

OIL FILL

HOLE

OIL PLUG

DIPSTICK