No. 700 Portable Power Drive

Ridge Tool Company

3

Tool Use and Care

• Use clamp or other practical way to secure and

support the workpiece to a stable platform. Holding

the work by hand or against your body is unstable and

may lead to loss of control.

• Do not force tool. Use the correct tool for your

application. The correct tool will do the job better

and safer at the same rate for which it is designed.

• Do not use if switch does not turn the tool ON or

OFF. Any tool that cannot be controlled with the switch

is dangerous and must be repaired.

• Disconnect the plug from the power source before

making any adjustments, changing accessories or

storing the tool. Such preventive safety measures

reduce the risk of starting the tool accidentally.

• Store idle tools out of the reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp

and clean. Properly maintained tools with sharp cut-

ting edges are less likely to bind and are easier to con-

trol.

• Check for misalignment or binding of moving

parts, breakage of parts and any other condition

that may affect the tool’s operation. If damaged,

have the tool serviced before using. Many accidents

are caused by poorly maintained tools.

• Use only accessories that are recommended for

your tool. Accessories that may be suitable for one

tool may become hazardous when used on another

tool.

• Keep handles dry and clean; free from oil and

grease. Allows for better control of the tool.

Service

• Tool service must be performed only by qualified

repair personnel. Service or maintenance performed

by unqualified repair personnel could result in injury.

• When servicing a tool, use only identical replace-

ment parts. Follow instructions in the Maintenance

Section of this manual. Use of unauthorized parts or

failure to follow maintenance instructions may create

a risk of electrical shock or injury.

Specific Safety Information

WARNING

Read this operator’s manual carefully before using

the 700 Power Drive. Failure to understand and fol-

low the contents of this manual may result in

electrical shock, fire and/or serious personal injury.

Call Ridge Tool Company, Technical Service Depart-

ment at (800) 519-3456 if you have any questions.

Power Drive Safety

• The Power Drive is made to turn threaders and

other equipment. Follow instructions in this Oper-

ator’s Manual on proper use when threading. When

using it to power other equipment, read and follow

the safety and operating instructions provided

with that equipment. Other uses may increase the

risk of serious injury.

• When threading one inch or larger pipe, secure

Power Drive using a No. 775 Support Arm. Hold

Power Drive firmly. If the Power Drive cannot be

secured by a Support Arm, use other mechanical

means such as a pipe wrench. Resists high handle

forces developed during use and prevents losing con-

trol of the tool.

• Do not use this power drive if switch is broken.

This switch is a safety device that lets you shut off the

motor by removing your finger.

• Do not wear gloves or loose clothing when oper-

ating Power Drive. Keep sleeves and jackets but-

toned. Do not reach across rotating tool parts or

workpiece. Clothing can be caught resulting in entan-

glement and serious injury.

• When using to power equipment other than thread-

ers, the 700 Power Drive may have to be secured

to resist high handle forces. Handle forces that are

developed will depend on the application. High handle

forces may cause serious injury.

• Do not use dull or damaged dies. Sharp cutting

dies require less torque and the Power Drive is easier

to control.

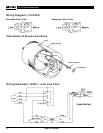

Description, Specifications and

Standard Equipment

Description

The RIDGID Model 700 Power Drive provides rotation-

al motion for threading pipe, conduit and rod (bolt stock)

and other purposes. Forward and Reverse rotation can

be selected with the REV/OFF/FOR switch.