Ridge Tool Company

7

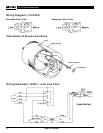

Figure 5 – Threading 2” Pipe With Power Drive

Positioned On Right Side Of Vise

Figure 6 – Threading Using Pipe Wrench As A Support

Arm

5. Place Die Head over end of pipe.

To avoid serious injury, make sure Power

Drive is correctly positioned on support arm (Figures 4, 5

& 6). For right hand threads, Die Head will rotate clockwise

(looking at the face of the Die Head). Forces developed by

the threading torque will be in the opposite or counter-

clockwise direction.

6. Simultaneously actuate the switch button and exert

pressure against the Die Head with the palm of free

hand to make sure thread is started. Apply plenty of

thread cutting oil to the dies during threading. This will

reduce the torque required to thread and improve

the thread quality.

7. Keep switch depressed until end of the pipe is even

with edge of the dies and release the switch button.

8. Back off the Die Head from the threaded pipe by

actuating the switch button in the reverse direction.

To avoid injury, hold onto the Power Drive

handle firmly to resist handle forces developed while

backing off the Die Head.

9. When dies clear the end of the pipe, grip the handle

on top of the Power Drive and remove the Power

Drive and Die Head from the pipe.

10. Remove the support arm from the pipe and the pipe

from the vise.

To avoid injury, make sure long sections of

pipe are supported at the end farthest away from the

vise prior to removal.

11. Clean up any oil spills or splatter on the ground sur-

rounding the vise and oiler.

Operation Instructions For

Threading With Geared

Threaders

WARNING

Do not wear gloves or loose clothing when oper-

ating Power Drive. Keep sleeves and jackets but-

toned. Do not reach across the geared threader.

Do not use this Power Drive if the switch is broken.

Always wear eye protection to protect eyes from

dirt and other foreign objects.

To prevent tipping, proper set-up of the Power

Drive and Geared Threader is required. Follow

instructions carefully.

Geared Threaders weigh 95 to 160 pounds. Two (2)

persons should be used to lift these threaders.

Adjusting Nos. 141 And 161 Geared

Threaders

Cam Plate (Pipe Size) Adjustment

Procedure

1. Place threader on floor or workbench with drive shaft

up.

No. 700 Portable Power Drive

No. 418 Oiler

Pipe

No. 775 Support Arm

Switch Button

WARNING

WARNING

WARNING